With the advent of electric heating, the core design purpose of the muffle furnace shifted from protecting a sample from a dirty heat source to perfecting the control of a clean one. The introduction of high-temperature electric heating elements in the 1950s made combustion by-products a non-issue, allowing furnace design to focus entirely on achieving superior temperature uniformity and a pristine heating environment.

While older fuel-fired muffle furnaces were designed around the complex challenge of isolating a sample from combustion, the shift to electric heating made the heat source itself clean. This pivotal change simplified furnace construction and allowed design to evolve, prioritizing precision, control, and purity above all else.

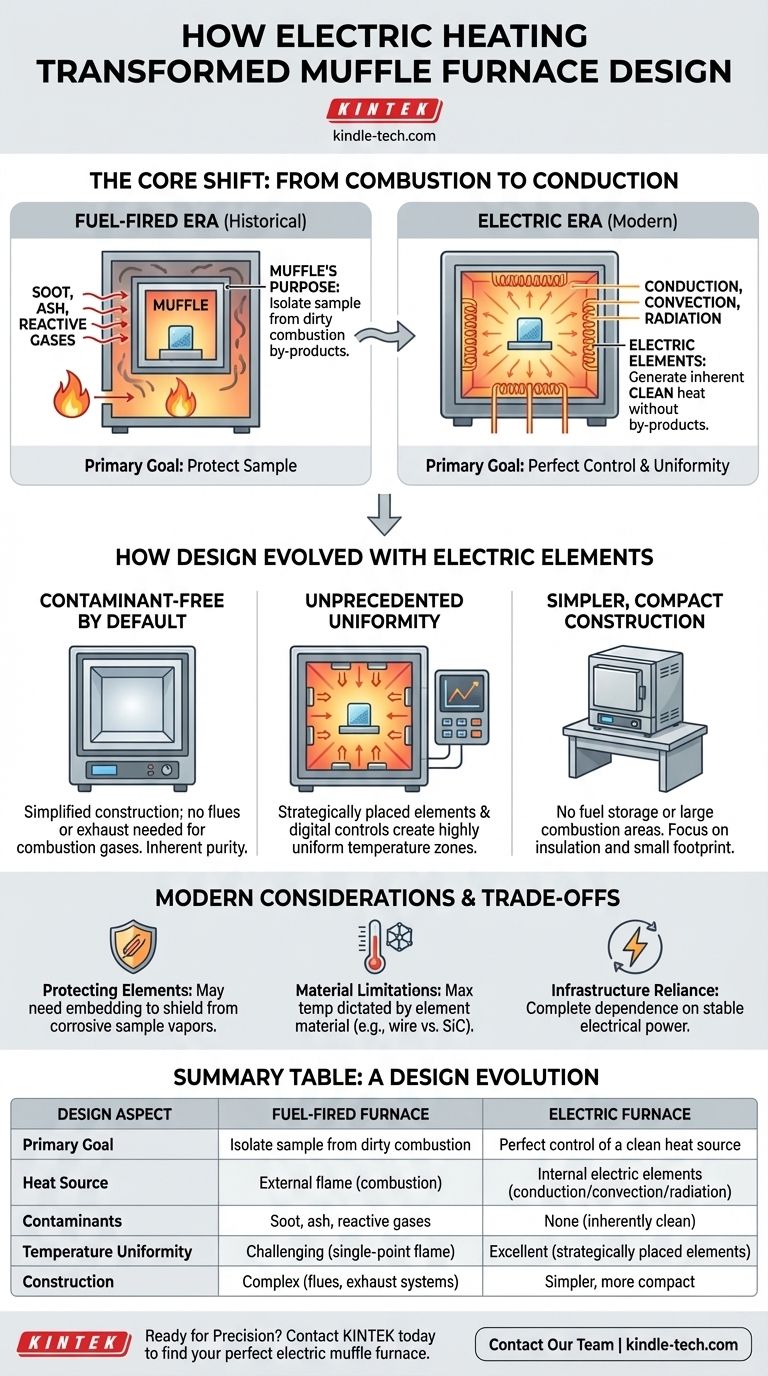

The Core Shift: From Combustion to Conduction

To grasp the significance of the change, one must first understand the fundamental problem that early muffle furnaces were built to solve.

The Challenge of Fuel-Fired Heat

Historically, achieving high temperatures meant burning a fuel source like coal, gas, or oil. This process of combustion is inherently "dirty," producing by-products like soot, ash, and reactive gases.

These contaminants could easily react with or deposit on the material being heated, ruining experiments, altering chemical compositions, and compromising the integrity of the final product.

The Original Purpose of the "Muffle"

The solution was the "muffle"—a sealed inner chamber made of a refractory material. The sample was placed inside this muffle, which was then heated externally by the flame.

This chamber-within-a-chamber design acted as a physical barrier. It protected the sample from the direct impact of the flame and its contaminants, ensuring a clean heating process. The primary design challenge was managing this separation effectively.

The Electric Revolution

The development of stable, high-temperature electric heating elements (like those made of electric wire, silicon carbide, or silicon molybdenum) changed everything.

Electric furnaces generate heat through conduction, convection, and radiation. Critically, none of these processes involve combustion, meaning they produce no chemical by-products. The heat source became fundamentally clean.

How Electric Elements Redefined Furnace Design

With a clean heat source, the original reason for the muffle—isolating the sample from fuel by-products—became obsolete. This allowed engineers to completely rethink furnace design and optimize it for new goals.

A Contaminant-Free Environment by Default

In an electric furnace, the entire chamber is inherently free from combustion contaminants. This simplifies construction, as complex flues and exhaust systems for managing combustion gases are no longer necessary. The focus shifts from isolation to containment.

Unprecedented Temperature Uniformity

Electric elements can be strategically placed around the interior of the furnace chamber. This allows for far more even heat distribution than a single-point flame source.

The result is a highly uniform temperature zone, which is critical for processes requiring extreme precision and repeatability. Digital controllers can manage the power to these elements with incredible accuracy.

Simpler, More Compact Construction

Eliminating the need for fuel storage, delivery lines, and large combustion areas allows electric muffle furnaces to be significantly more compact.

Their design can focus on maximizing insulation thickness and minimizing physical footprint, making them ideal for laboratory and workshop environments where space is a premium.

Common Pitfalls and Modern Considerations

While electric heating solved the contamination problem, it introduced a new set of design considerations that are important to understand.

Protecting the Elements, Not Just the Sample

In a reversal of the original design problem, the heating elements themselves must now sometimes be protected from the sample.

Certain processes release corrosive vapors or gases that can degrade the electric elements over time. Because of this, many modern furnaces embed the elements within the refractory insulation to shield them, extending their operational life.

Material and Temperature Limitations

The maximum achievable temperature of an electric furnace is dictated by the material of its heating elements. Standard wire elements have lower limits, while silicon carbide or molybdenum disilicide elements can reach much higher temperatures but come at a greater cost.

The choice of element is therefore a critical design decision tied directly to the furnace's intended application and price point.

Reliance on Electrical Infrastructure

The most obvious trade-off is the complete dependence on a stable and sufficient electrical power supply. Unlike fuel-fired alternatives, an electric furnace's performance is tied directly to the quality of its electrical service.

Making the Right Choice for Your Goal

The design evolution of the muffle furnace directly translates to specific benefits for modern applications. When selecting a furnace, your primary goal should guide your decision.

- If your primary focus is material purity and analysis: An electric furnace is the only choice, as its inherently contaminant-free environment ensures results are not skewed by combustion by-products.

- If your primary focus is process repeatability and precision: The superior temperature control and uniformity of an electric design are non-negotiable for achieving consistent outcomes in applications like heat treating or materials research.

- If your primary focus is operational simplicity and safety: Electric furnaces offer easier integration with programmable digital controls and eliminate the handling risks and infrastructure associated with combustible fuels.

Understanding this evolution from managing combustion to mastering control allows you to select the precise tool your work demands.

Summary Table:

| Design Aspect | Fuel-Fired Furnace | Electric Furnace |

|---|---|---|

| Primary Goal | Isolate sample from dirty combustion | Perfect control of a clean heat source |

| Heat Source | External flame (combustion) | Internal electric elements (conduction/convection/radiation) |

| Contaminants | Soot, ash, reactive gases | None (inherently clean) |

| Temperature Uniformity | Challenging (single-point flame) | Excellent (strategically placed elements) |

| Construction | Complex (flues, exhaust systems) | Simpler, more compact |

Ready to leverage the precision of modern electric muffle furnaces in your lab?

KINTEK specializes in high-performance laboratory equipment, including a range of electric muffle furnaces designed for superior temperature control and contaminant-free heating. Whether your work requires material purity, process repeatability, or operational simplicity, our experts can help you select the perfect furnace for your application.

Contact our team today to discuss your specific needs and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the process of a muffle furnace? From Electricity to Precision High-Temp Control

- Which furnace is used for sintering? A Guide to Choosing the Right System for Your Application

- What is the importance of muffle furnace in laboratory? Achieve Precise, Contaminant-Free Heating

- What role does a high-temperature muffle furnace play in LDH-derived photocatalysts? Engineer Superior Metal Oxides

- Why is a laboratory drying oven necessary for preheating raw materials prior to the smelting of stainless steel alloys?

- What is the role of a muffle furnace in magnetite pellet roasting? Optimize Mineral Phase & Compressive Strength

- What is a microwave furnace? Unlock Faster, More Uniform Heating for Advanced Materials

- What role does a high-temperature muffle furnace play in the preparation of TiO2 nanoparticles? Key Thermal Insights