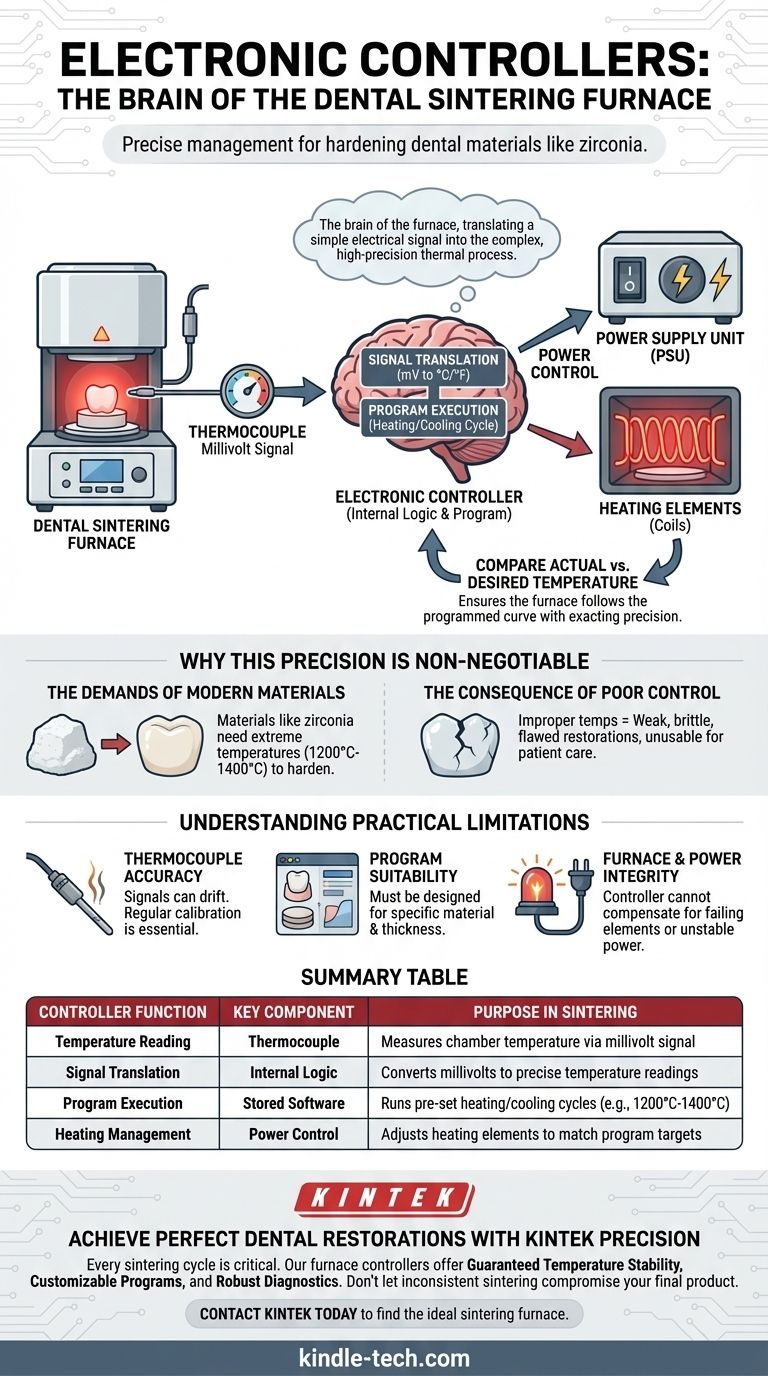

In a dental sintering furnace, an electronic controller serves two primary functions: it precisely measures the internal temperature by interpreting a signal from a sensor and then uses computer logic to execute a pre-programmed heating and cooling cycle. This dual capability allows it to manage the extreme temperatures required to harden dental materials like zirconia.

The controller is the brain of the furnace, translating a simple electrical signal into the complex, high-precision thermal process required to transform a milled restoration into a hard, durable, and patient-ready final product.

The Core Function: From Signal to Control

To understand the controller, it's best to break its function down into a clear, sequential process. It is not merely an on/off switch but an active management system.

Reading the Temperature

The process begins with a sensor, typically a thermocouple, placed inside the furnace chamber. This thermocouple generates a very small electrical signal, measured in millivolts, that changes in direct proportion to the temperature. The controller's first job is to function as a highly sensitive voltmeter, accurately reading this faint signal.

Translating the Signal

A raw millivolt signal is not a useful temperature reading. The controller's internal logic instantly converts this voltage into a precise temperature measurement, such as Celsius or Fahrenheit. This translation is the foundation for all subsequent actions.

Executing the Sintering Program

The controller contains computer hardware that stores and runs specific heating programs. These programs dictate the target temperature at every stage of the sintering cycle—from the initial ramp-up, to the high-temperature hold, to the controlled cool-down.

Managing the Heating Elements

At every moment, the controller compares the actual temperature (from the thermocouple) to the desired temperature (from the program). If the actual temperature is too low, it sends power to the heating elements. If it's too high, it cuts the power, ensuring the furnace follows the programmed curve with exacting precision.

Why This Precision is Non-Negotiable

The controller's role is critical because the sintering process itself is a delicate science. Sintering is the process of using high heat to fuse ceramic particles together, giving a restoration its final strength and stability.

The Demands of Modern Materials

Dental materials like zirconia are milled into crowns, bridges, or frameworks in a soft, chalk-like state. They only achieve their final, formidable hardness after being subjected to temperatures often between 1200°C and 1400°C in a sintering furnace.

The Consequence of Poor Control

Without the precise management of an electronic controller, the entire process fails. Improper temperatures or heating rates can result in a restoration that is weak, brittle, dimensionally inaccurate, or aesthetically flawed, rendering it completely unusable for patient care.

Understanding the Practical Limitations

While modern controllers are highly reliable, their effectiveness is dependent on the entire system. Understanding these factors is key to achieving consistent results.

Thermocouple Accuracy

The controller is only as accurate as the information it receives. Thermocouples can degrade over time, causing their signals to "drift." This leads to the controller receiving an incorrect temperature reading, which compromises the entire cycle. Regular calibration is essential.

Program Suitability

A controller can perfectly execute a flawed program. The programmed heating cycle must be specifically designed for the type and thickness of the material being sintered. Using a generic program for a specialized ceramic can lead to poor outcomes.

Furnace and Power Integrity

The controller tells the heating elements what to do, but it cannot compensate for failing elements or an unstable power supply. Fluctuations in voltage can prevent the furnace from hitting its target temperatures, even with a perfectly functioning controller.

How to Apply This to Your Practice

The ideal controller function depends entirely on the specific needs of your dental lab or practice.

- If your primary focus is consistency for standard zirconia restorations: A controller with reliable, manufacturer-validated pre-set programs and excellent temperature stability is your most critical asset.

- If your primary focus is working with a wide range of advanced ceramics: You need a controller with fully customizable, multi-stage programming capabilities to create unique cycles for different materials.

- If your primary focus is operational uptime and quality control: Prioritize a controller that features self-diagnostics, data logging, and straightforward calibration procedures to ensure accuracy and minimize downtime.

Ultimately, the electronic controller is the critical component that guarantees the transformation of a milled block into a precise and durable final restoration.

Summary Table:

| Controller Function | Key Component | Purpose in Sintering |

|---|---|---|

| Temperature Reading | Thermocouple | Measures chamber temperature via millivolt signal |

| Signal Translation | Internal Logic | Converts millivolts to precise temperature readings |

| Program Execution | Stored Software | Runs pre-set heating/cooling cycles (e.g., 1200°C-1400°C) |

| Heating Management | Power Control | Adjusts heating elements to match program targets |

Achieve Perfect Dental Restorations with KINTEK Precision

Every sintering cycle is critical. A precise electronic controller ensures your dental zirconia reaches its full strength and durability without flaws. At KINTEK, we specialize in laboratory equipment designed for accuracy and reliability.

Our furnace controllers offer:

- Guaranteed Temperature Stability for consistent results on every restoration.

- Customizable Programs tailored to your specific materials and workflows.

- Robust Diagnostics & Calibration Support to maintain peak performance.

Don't let inconsistent sintering compromise your final product.

Contact KINTEK today to find the ideal sintering furnace for your dental lab's needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is dental ceramic used for? Restore Teeth with Aesthetic, Durable Crowns & Fillings

- How can consistent heating of ceramic restorations be achieved within a furnace? Master Your Furnace's Heat Dynamics

- What are some features found in many modern dental ovens? Enhancing Precision Through Digital Integration

- What type of zirconia has better esthetics? Choose High-Translucency 4Y/5Y Zirconia for Superior Beauty

- What is the temperature of the burnout oven? Master the Multi-Stage Cycle for Flawless Castings

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of different sintering process on flexural strength of translucency monolithic zirconia? Optimize Strength vs. Efficiency

- What is the average lifespan of a dental restoration? Maximize Your Investment with the Right Material