The fundamental difference between a rotary vane pump and a liquid ring pump lies in how they create a vacuum and what they can handle. Rotary vane pumps use sliding vanes and tight mechanical tolerances to generate a high, clean vacuum, making them ideal for dry processes. In contrast, liquid ring pumps use a rotating ring of liquid to create a vacuum, allowing them to handle wet, vapor-heavy, and even dirty gas streams with exceptional robustness.

Your choice is not about which pump is superior, but which is suited for your specific process stream. You are selecting between the high-precision vacuum of a rotary vane pump and the rugged, contaminant-handling capability of a liquid ring pump.

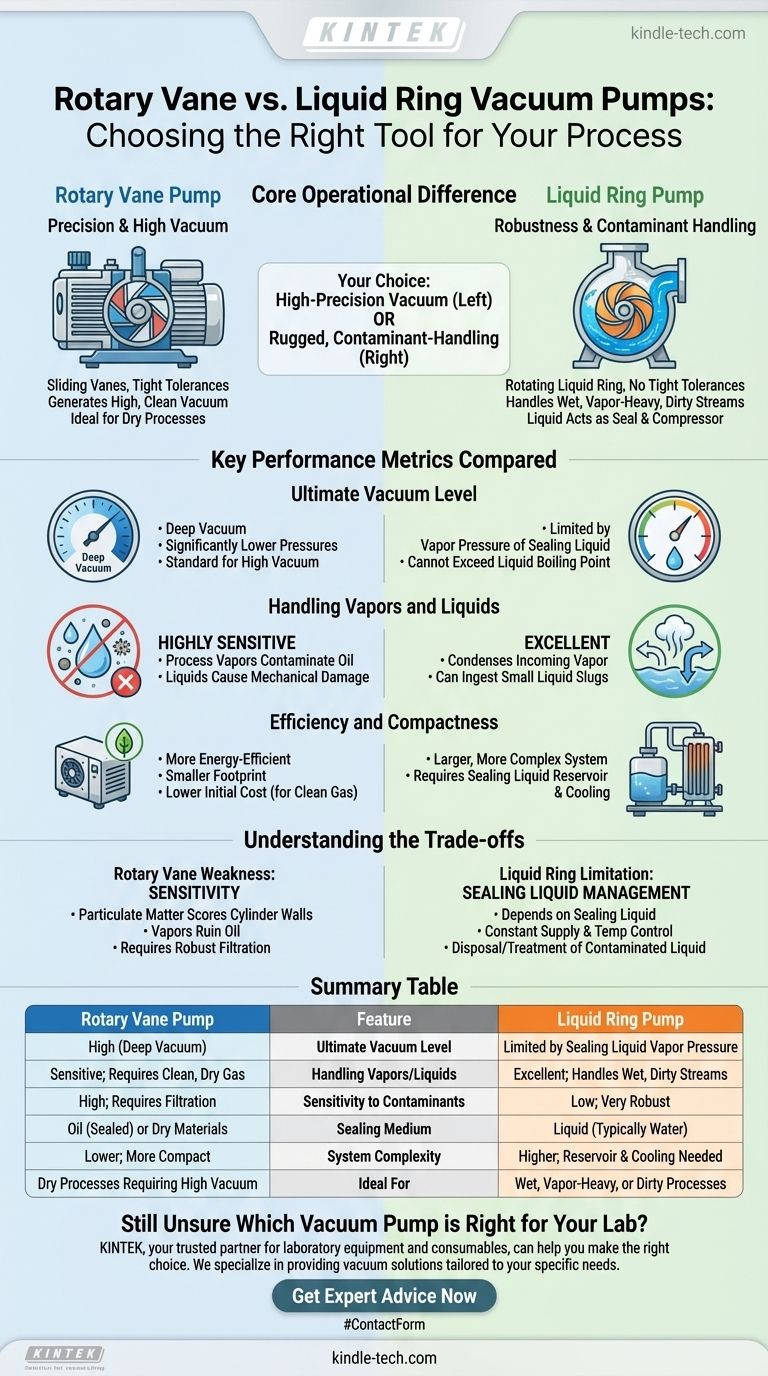

The Core Operational Difference

To choose correctly, you must first understand how each pump works. Their distinct mechanisms are the source of all their respective strengths and weaknesses.

Rotary Vane Pumps: Precision and High Vacuum

A rotary vane pump features a rotor that is offset within a cylindrical housing. This rotor has slots containing vanes that slide in and out, pressing against the housing walls as it spins.

This action creates expanding and contracting chambers, which trap, compress, and exhaust gas molecules from the system. They come in two main types: oil-sealed, which use oil for lubrication and to create a superior seal, and dry-running, which use self-lubricating materials like graphite and rely on extremely tight tolerances.

Liquid Ring Pumps: Robustness and Contaminant Handling

A liquid ring pump also uses an eccentrically mounted rotor (an impeller with fixed blades). As it spins, centrifugal force throws a sealing liquid—typically water—against the outer wall of the pump's housing, forming a stable ring of liquid.

Because the impeller is offset, the pockets between its blades and the liquid ring expand and contract. This action draws in and compresses the process gas. The liquid ring itself acts as the dynamic seal and the compression medium, eliminating the need for tight mechanical tolerances.

Key Performance Metrics Compared

Your process requirements will map directly to one of these pump's performance characteristics. The most important metrics are the ultimate vacuum level and the ability to handle process contaminants.

Ultimate Vacuum Level

Rotary vane pumps are the clear winner for achieving a deep vacuum. An oil-sealed rotary vane pump can reach pressures significantly lower than a liquid ring pump, making it the standard for applications requiring high vacuum.

Liquid ring pumps are limited by the vapor pressure of their sealing liquid. The pump cannot create a vacuum deeper than the pressure at which its own sealing liquid begins to boil.

Handling Vapors and Liquids

Liquid ring pumps excel at handling gas streams saturated with vapors. The cool sealing liquid can condense a significant portion of incoming vapor, increasing the pump's effective capacity. They can even ingest small slugs of liquid without damage.

Rotary vane pumps are highly sensitive to vapors and liquids. In an oil-sealed pump, process vapors can contaminate the sealing oil, degrading pump performance and requiring frequent, costly oil changes. Liquids can cause severe mechanical damage.

Efficiency and Compactness

For a clean, dry gas load, a rotary vane pump is generally more energy-efficient and has a much smaller footprint. Its compact design and lower initial cost make it a cost-effective choice for many applications.

A liquid ring pump system is larger and more complex. It requires a reservoir for the sealing liquid, a separator to remove it from the exhaust stream, and often a heat exchanger to control its temperature.

Understanding the Trade-offs

Neither pump is a perfect solution. Acknowledging their inherent limitations is critical to avoiding costly mistakes and operational downtime.

The Rotary Vane Weakness: Sensitivity

The primary trade-off for a rotary vane pump's high performance is its sensitivity. Particulate matter can score the cylinder walls, and process vapors can ruin the oil. This necessitates robust inlet filtration and makes them unsuitable for dirty or wet processes.

The Liquid Ring Limitation: Sealing Liquid Management

A liquid ring pump's robustness depends entirely on its sealing liquid. You must manage a constant supply, control its temperature, and deal with its disposal. If the process gas contaminates the sealing liquid, it may need to be treated as industrial waste, adding operational complexity and cost.

Making the Right Choice for Your Application

The decision hinges on the nature of the gas you need to pump. Analyze your process stream first, then select the pump that aligns with its characteristics.

- If your primary focus is achieving a high, clean vacuum for a dry process: Choose a rotary vane pump for its efficiency and deep vacuum capability.

- If your primary focus is handling wet, vapor-heavy, or dirty gas streams: Choose a liquid ring pump for its unparalleled robustness and ability to handle contaminants.

- If your primary focus is an oil-free system with high vacuum: A dry-running rotary vane pump is your best option, but ensure your process gas is free of particulates and condensable vapors.

- If your primary focus is low capital cost for a simple, clean application: An oil-sealed rotary vane pump is often the most economical choice.

The right choice depends not on which pump is "better," but on which is best suited to the unique demands of your process.

Summary Table:

| Feature | Rotary Vane Pump | Liquid Ring Pump |

|---|---|---|

| Ultimate Vacuum Level | High (deep vacuum) | Limited by sealing liquid vapor pressure |

| Handling Vapors/Liquids | Sensitive; requires clean, dry gas | Excellent; can handle wet, dirty streams |

| Sensitivity to Contaminants | High; requires filtration | Low; very robust |

| Sealing Medium | Oil (sealed) or self-lubricating materials (dry) | Liquid (typically water) |

| System Complexity | Lower; more compact | Higher; requires liquid reservoir & cooling |

| Ideal For | Dry processes requiring high vacuum | Wet, vapor-heavy, or dirty processes |

Still Unsure Which Vacuum Pump is Right for Your Lab?

Choosing between a rotary vane and a liquid ring pump is critical for your process efficiency and equipment longevity. KINTEK, your trusted partner for laboratory equipment and consumables, can help you make the right choice.

We specialize in providing vacuum solutions tailored to the specific needs of research and industrial labs. Whether you require the high vacuum of a rotary vane pump for sensitive applications or the ruggedness of a liquid ring pump for challenging conditions, our experts will guide you to the optimal solution.

Contact us today to discuss your application requirements and let us help you select the perfect pump for your lab.

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What is the origin of sintering? Discover the Prehistoric Evolution of Thermal Fusion and Ancient Ceramics

- What temperature is THC short path distilled? Master the 180°C-200°C Range for Purity

- Why is an additional annealing process required following silicification? Ensure Composite Stability & Durability

- What are the risk and protective factors of CVD? Take Control of Your Heart Health Today

- What types of biological materials can be safely stored at -70C? A Guide to Long-Term Sample Preservation

- Why are vacuum drying and argon purging equipment necessary for SILP catalyst impregnation? Optimize Performance Now

- What is the relationship between sintering temperature and melting point? A Guide to Controlled Thermal Processing

- What are the factors affecting sintering? Master the Key Variables for Optimal Densification