To solve issues caused by incorrect pressing times, some modern press furnaces utilize an automated process. This intelligent feature monitors the procedure and automatically stops the press program at the optimal moment, ensuring a complete press without the negative effects of excessive hold times.

The central challenge with dental pressing is that a fixed timer is a poor substitute for knowing when a press is actually complete. Modern furnaces solve this by replacing manual guesswork with an automated system that stops the process precisely when the restoration is fully formed, eliminating a critical point of failure.

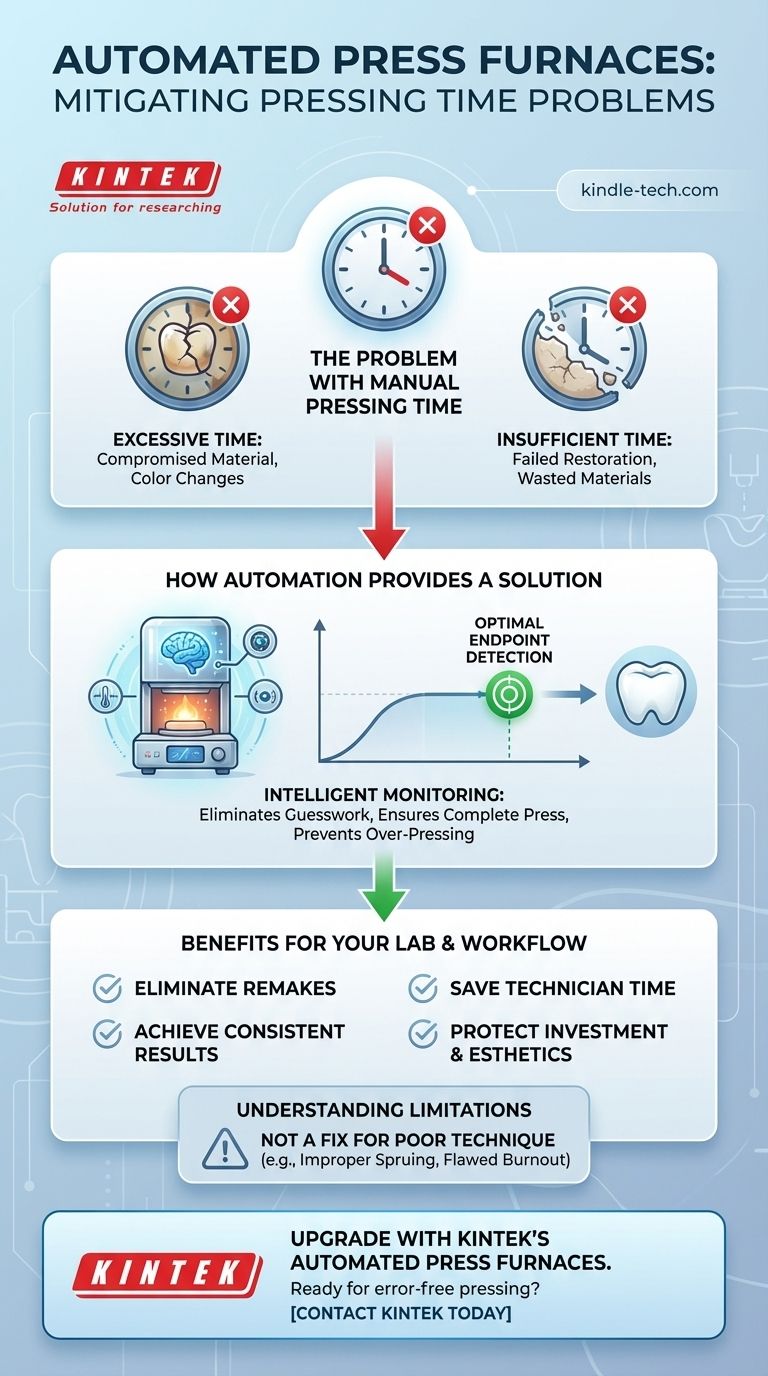

The Problem with Manual Pressing Time

Traditionally, technicians had to calculate and set pressing times manually. This approach is inherently prone to error and can lead to inconsistent results, even for experienced professionals.

The Consequences of Excessive Time

When a restoration is held under pressure and temperature for too long, its material properties can be compromised. This can result in undesirable color changes or alterations to the physical integrity of the ceramic.

The Risk of Insufficient Time

The more obvious risk of manual timing is setting the duration too short. An incomplete press results in a failed restoration, wasting valuable materials, investment, and technician time, forcing the entire process to be repeated.

How Automation Provides a Solution

Automated press functions are designed to remove the guesswork entirely. Instead of relying on a pre-set timer, the furnace intelligently determines the exact point of completion.

Optimal Endpoint Detection

The key feature is the furnace's ability to recognize when the pressing process is finished. It automatically concludes the program at this optimal point.

Ensuring a Complete Press

This automated stop ensures that every press is fully completed, preventing the failures and remakes associated with insufficient press times.

Preventing Over-Pressing Defects

By stopping the moment the press is complete, the furnace also prevents the negative effects of over-pressing. This protects the restoration from color shifts and maintains its intended physical properties, leading to more predictable and esthetic outcomes.

Understanding the Limitations

While this automation is a significant advancement, it's essential to recognize what it does and does not solve. It is a powerful tool, not a replacement for fundamental best practices.

Not a Fix for Poor Technique

This technology specifically addresses the variable of pressing time. It cannot compensate for errors in other critical areas, such as improper spruing, incorrect investment procedures, or a flawed burnout cycle.

Reliance on the System

The accuracy of the outcome depends on the proper functioning and calibration of the furnace's automated system. Technicians must still ensure the equipment is maintained and operated according to the manufacturer's guidelines.

Applying This to Your Workflow

Choosing equipment with this feature depends on your lab's specific goals regarding consistency, efficiency, and quality control.

- If your primary focus is minimizing remakes and ensuring consistency: An automated press furnace is a highly valuable investment that eliminates a major source of process variability.

- If your primary focus is on operator-driven control: A manual furnace can still yield excellent results but requires strict adherence to standardized protocols to mitigate the risks of timing errors.

Leveraging automation for pressing time allows you to shift your focus from managing process variables to perfecting the final restoration.

Summary Table:

| Problem with Manual Pressing | Automated Furnace Solution |

|---|---|

| Inconsistent results due to human error | Intelligent system monitors and stops at optimal completion point |

| Risk of over-pressing (color shifts, weakened integrity) | Prevents excessive hold times, protecting material properties |

| Risk of under-pressing (failed restorations, remakes) | Ensures complete press every time, reducing waste and labor |

| Reliance on technician experience and guesswork | Removes variability, standardizes the pressing process for all skill levels |

Upgrade your dental lab with KINTEK's automated press furnaces.

Stop wasting time and materials on inconsistent presses and remakes. Our advanced furnaces are designed for dental laboratories like yours, featuring intelligent automation that guarantees a complete, perfect press every time—eliminating the guesswork and risks of manual timing.

Benefits for your lab:

- Eliminate remakes caused by under- or over-pressing

- Achieve consistent, predictable results across all your restorations

- Save valuable technician time by automating a critical variable

- Protect your investment in materials and ensure esthetic outcomes

Ready to achieve error-free pressing and enhance your lab's efficiency? Contact KINTEK today to find the perfect press furnace for your needs.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What are the advantages of using vacuum hot pressing for SiC/Al composites? Achieve Superior Microstructural Control

- Why is it necessary to maintain a high-vacuum environment within a vacuum hot press furnace? Optimize Cu-SiC Sintering

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production