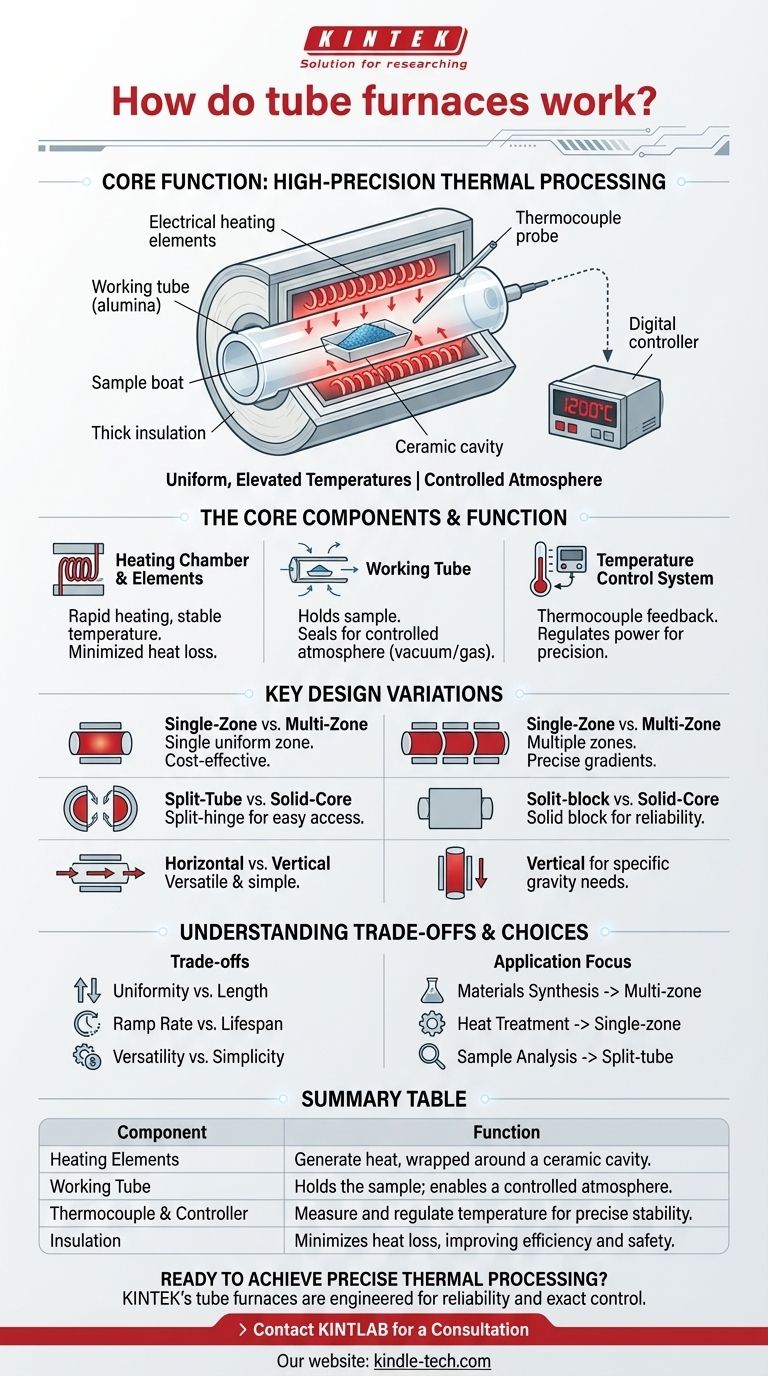

At its core, a tube furnace is a high-precision oven designed for processing materials at uniform, elevated temperatures. It operates by using electrical heating elements, typically coils, wrapped around a cylindrical ceramic cavity. A separate, sealed "working tube" containing the material sample is placed inside this heated zone, and a thermocouple provides real-time temperature feedback to a controller, which modulates power to maintain a precise and stable thermal environment.

A tube furnace provides a highly uniform and precisely controlled high-temperature environment. Its fundamental design isolates a sample within a tube, enabling thermal processing under a controlled atmosphere—such as a vacuum or a specific gas—which is critical for advanced materials synthesis and analysis.

The Core Components and Their Function

To understand how a tube furnace achieves such precision, it's essential to break down its primary components. Each part plays a critical role in the overall function.

The Heating Chamber and Elements

The outer body of the furnace is a cylindrical chamber containing the heating elements. These are surrounded by a high-density, thermally insulating matrix.

This design enables rapid heating and cooling while minimizing heat loss to the surrounding environment, ensuring both energy efficiency and a stable internal temperature.

The Working Tube

This is the vessel that holds the sample. It is inserted through the center of the heated chamber. Tubes are typically made of alumina, quartz, or ceramic, chosen based on the required temperature and chemical compatibility.

Crucially, the working tube can be sealed at the ends, allowing for the creation of a controlled atmosphere. This is what enables processes like vacuum brazing, sintering, or growing materials in an inert gas environment. Samples are often placed in smaller "boats" and slid into the tube's center.

The Temperature Control System

This is the brain of the furnace. A thermocouple, a temperature-sensing probe, is placed near the heating elements or the working tube.

It constantly measures the temperature and sends this data to a digital controller. The controller compares the actual temperature to the user-set target and adjusts the power supplied to the heating elements to eliminate any deviation.

Key Design Variations

Not all tube furnaces are the same. Their design varies based on the intended application, influencing their capabilities and cost.

Single-Zone vs. Multi-Zone

A single-zone furnace has one set of heating elements and one controller, creating a single, uniform hot zone in the center. This is the most common and cost-effective configuration.

A multi-zone furnace has two or more independent heating zones along the length of the tube, each with its own thermocouple and controller. This allows for an exceptionally long and uniform hot zone or the creation of precise temperature gradients.

Split-Tube vs. Solid-Core

A solid-core furnace is a single, solid cylinder. The working tube must be inserted and removed from one of the ends.

A split-tube (or split-hinge) furnace is built in two halves that can be opened. This allows for much easier placement and observation of the working tube, which is ideal for experiments that need quick access or have complex setups.

Horizontal vs. Vertical Orientation

Most tube furnaces are used in a horizontal position, which is simple and versatile.

Some split-tube models can be oriented vertically. This is useful for processes where gravity is beneficial, such as preventing powdered samples from contaminating the tube or for specific crystal growth applications.

Understanding the Trade-offs

While powerful, tube furnaces have inherent design trade-offs that are important to recognize for proper use and selection.

Uniformity vs. Tube Length

Achieving a perfectly uniform temperature becomes more difficult as the length of the heated zone increases. A longer tube will naturally have cooler temperatures at its ends. Multi-zone furnaces are the solution to this, but they add significant cost and complexity.

Ramp Rate vs. Element Lifespan

While many furnaces are capable of rapid heating (a high "ramp rate"), doing so repeatedly puts significant thermal stress on the heating elements. For non-critical processes, a slower ramp rate can extend the life of these expensive components.

Versatility vs. Simplicity

Features like split-hinge design, multi-zone control, and vacuum-compatible flanges dramatically increase the furnace's versatility. However, they also increase the purchase price and operational complexity. A simple, solid-core, single-zone furnace remains a rugged and reliable workhorse for many standard applications.

Making the Right Choice for Your Application

The ideal furnace configuration depends entirely on your primary goal. Use these points to guide your decision-making.

- If your primary focus is materials synthesis (e.g., graphene, composites): You need precise control over both temperature and atmosphere, making a gas-compatible, multi-zone furnace the superior choice.

- If your primary focus is routine heat treatment or annealing: A single-zone, solid-core horizontal furnace offers the best balance of performance, durability, and cost.

- If your primary focus is sample testing and analysis (e.g., aerospace metals, soil testing): A split-tube design will significantly improve your workflow by allowing for rapid sample exchange and easier setup.

By understanding these core principles, you can select and operate a tube furnace not just as a tool, but as a precise instrument for achieving your specific scientific or industrial goals.

Summary Table:

| Component | Function |

|---|---|

| Heating Elements | Generate heat, wrapped around a ceramic cavity. |

| Working Tube | Holds the sample; enables a controlled atmosphere. |

| Thermocouple & Controller | Measure and regulate temperature for precise stability. |

| Insulation | Minimizes heat loss, improving efficiency and safety. |

Ready to achieve precise thermal processing in your lab?

KINTEK's tube furnaces are engineered for reliability and exact control, whether your application involves materials synthesis, heat treatment, or sample analysis. Our expertise in lab equipment ensures you get the right configuration—single or multi-zone, horizontal or vertical—to meet your specific needs.

Let our specialists help you select the ideal furnace for your workflow. Contact KINTLAB today for a consultation!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- How is temperature controlled in a furnace? Mastering Precise Thermal Management

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation