Adjusting the temperature on a muffle furnace is a straightforward process executed via the digital control panel. You will typically press a 'Set' or 'Temperature Set' button, use arrow keys to change the target temperature value (often displayed in green), and then press the button again to confirm. This target is the "setpoint" the furnace will automatically work to achieve and maintain.

While pressing the buttons is simple, the key to successful operation lies in understanding that you are not just turning up a dial. You are providing a target to a sophisticated control system that uses a feedback loop to precisely manage the furnace's internal temperature.

The Core Components of Temperature Control

To operate the furnace effectively, you must understand its user interface and the underlying technology. These components work together to translate your input into a stable, high-temperature environment.

The Control Panel and Display

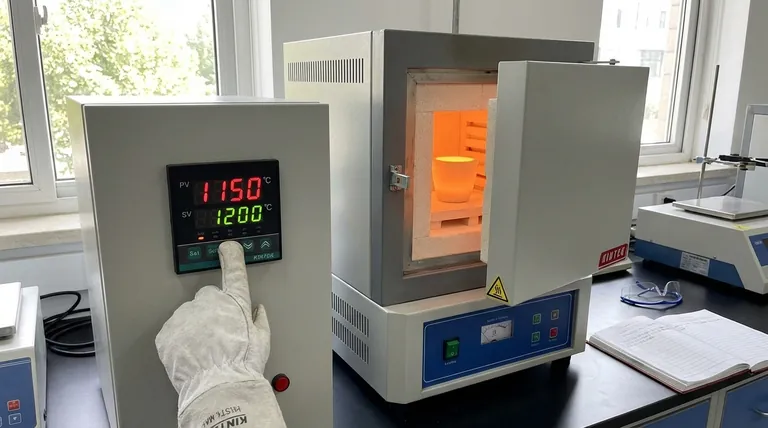

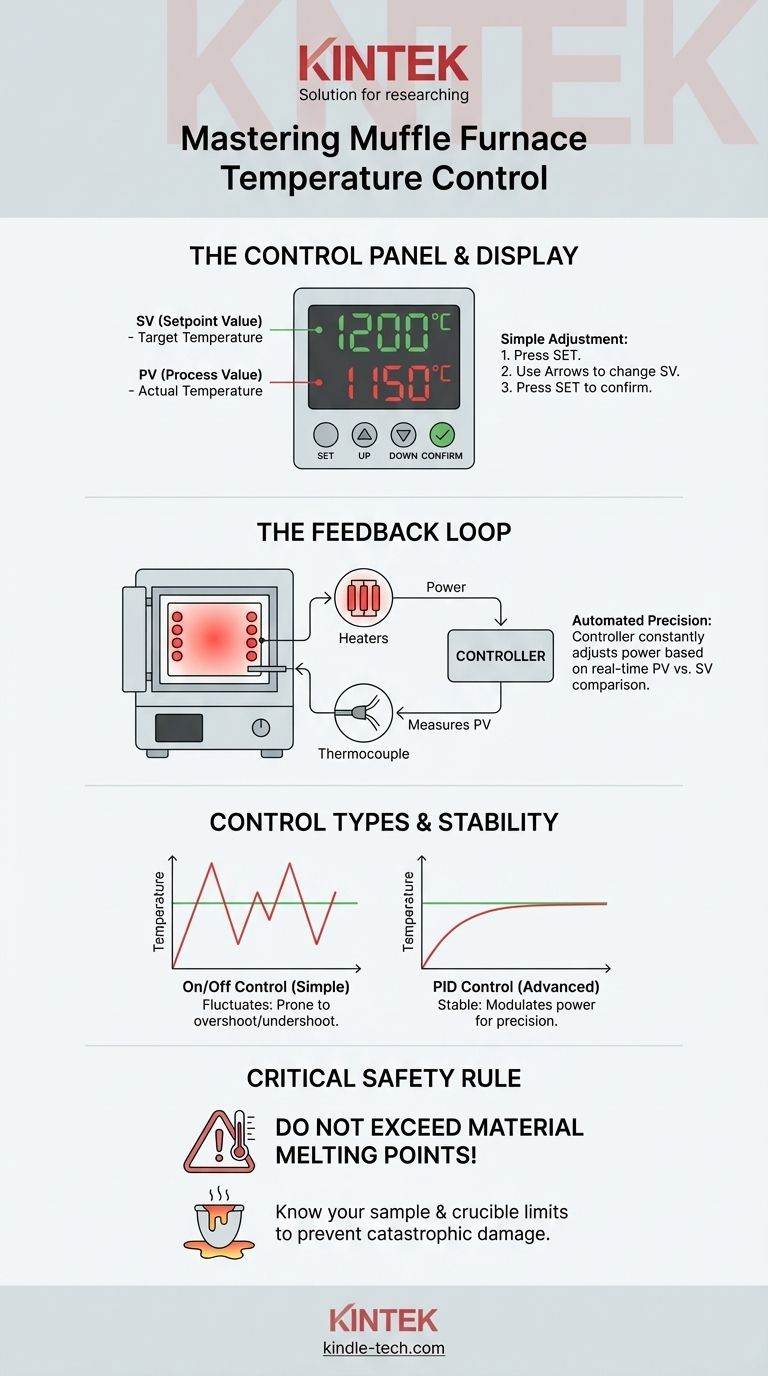

Most modern muffle furnaces feature a digital control panel with a dual display. You will typically see two numbers: the Setpoint Value (SV) and the Process Value (PV).

The SV is the target temperature you input. This is often shown in green and is the value you will adjust.

The PV is the actual, real-time temperature inside the furnace chamber, measured by a sensor. This is often displayed in red.

Setting the Temperature Setpoint

The process универсаally involves a few simple steps.

- Press the 'Temperature Set' or equivalent button to enter adjustment mode. The SV number will usually begin to flash.

- Use the dedicated 'Up' and 'Down' arrow buttons to increase or decrease the SV to your desired working temperature.

- Press the 'Set' button again to confirm your selection. The SV will stop flashing, and the furnace's control system now has its target.

The Thermocouple and Feedback Loop

The furnace controls its temperature through a process of feedback adjustment. A sensor, typically a thermocouple, constantly measures the actual internal temperature (the PV).

The furnace's controller compares this real-time temperature (PV) to your required temperature (SV). If the PV is lower than the SV, the controller sends power to the heating elements. If the PV is higher, it cuts power.

How the Furnace Manages Heat

Once you input the setpoint and turn on the main power, the furnace begins its work. The efficiency and precision of this process depend on the sophistication of its controller.

The Heating-Up Phase

After you confirm the setpoint, you will see the PV begin to climb. This rise indicates that the heating elements are active and the system is operating correctly. The furnace will continue to apply power until the PV nears the SV.

The Principle of Automatic Control

The furnace's goal is to stabilize its temperature. The method it uses to do this determines its precision.

Common controllers range from simple to complex. A two-position (on/off) controller simply turns the heaters on when it's too cold and off when it's too hot. This is effective but can lead to temperature "overshoot" and "undershoot," where the temperature fluctuates around your setpoint.

More advanced furnaces use Proportional-Integral-Derivative (PID) controllers. These are smarter systems that modulate the amount of power sent to the heaters, allowing the furnace to approach the setpoint smoothly and hold it with minimal fluctuation.

Understanding Critical Limitations

Setting the temperature correctly is only part of the equation. Safe and successful operation requires awareness of the physical limits of both the furnace and its contents.

Do Not Exceed Material Melting Points

This is the most critical rule. A muffle furnace can reach temperatures of 1800°C (3272°F) or higher, which is well above the melting point of many metals, glasses, and ceramics.

Before operation, you must know the melting point of your sample and your crucible. Placing a material in a furnace set higher than its melting point will destroy the sample and can cause catastrophic damage to the furnace's internal chamber.

Temperature Stability and Overshoot

Be aware that the actual temperature (PV) may temporarily exceed your setpoint (SV), especially with simpler on/off controllers. If your process is highly sensitive, allow the furnace to run for a period to ensure the temperature has fully stabilized within an acceptable range around your setpoint before introducing your sample.

How to Apply This to Your Process

Your specific goal determines which aspect of temperature control is most important.

- If your primary focus is standard heat-treatment or ashing: Concentrate on setting the correct final temperature and allowing the furnace to fully stabilize before you begin timing the process.

- If your process is sensitive to temperature fluctuations: Select a furnace with PID control, as it will provide a much more stable and precise heating environment.

- If you are working with any material, familiar or not: Always verify the melting points of your sample and crucible to prevent equipment damage and ensure a successful outcome.

Mastering temperature control is the foundation for achieving reliable and repeatable results in your high-temperature applications.

Summary Table:

| Control Element | Function | Key Consideration |

|---|---|---|

| Setpoint (SV) | Target temperature you set | Always confirm the setting |

| Process Value (PV) | Actual, real-time temperature | Monitors furnace status |

| Control Type | On/Off or PID (Proportional-Integral-Derivative) | PID offers superior stability |

| Critical Rule | Do not exceed material melting points | Prevents sample and furnace damage |

Achieve precise and reliable high-temperature results with KINTEK.

Mastering your muffle furnace's temperature control is crucial for consistent ashing, heat treatment, and sintering processes. Whether your lab requires standard benchtop models or advanced furnaces with sophisticated PID controllers for sensitive applications, KINTEK has the right equipment for you.

Our experts can help you select the perfect furnace to ensure temperature stability, prevent overshoot, and protect your valuable samples. Contact us today to discuss your specific laboratory needs and how our reliable lab equipment can enhance your workflow.

Get in touch with our specialists now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What does a high ash content mean? A Guide to Material Quality & Contamination

- What is the theory of muffle furnace? Achieve Pure, Controlled High-Temperature Processing

- What is the use of muffle furnace in soil? Analyze Soil Composition with High-Temperature Precision

- What are the methods of ash determination? Choosing the Right Technique for Accurate Mineral Analysis

- What is the critical point of heat treatment? Master the Key to Steel Transformation