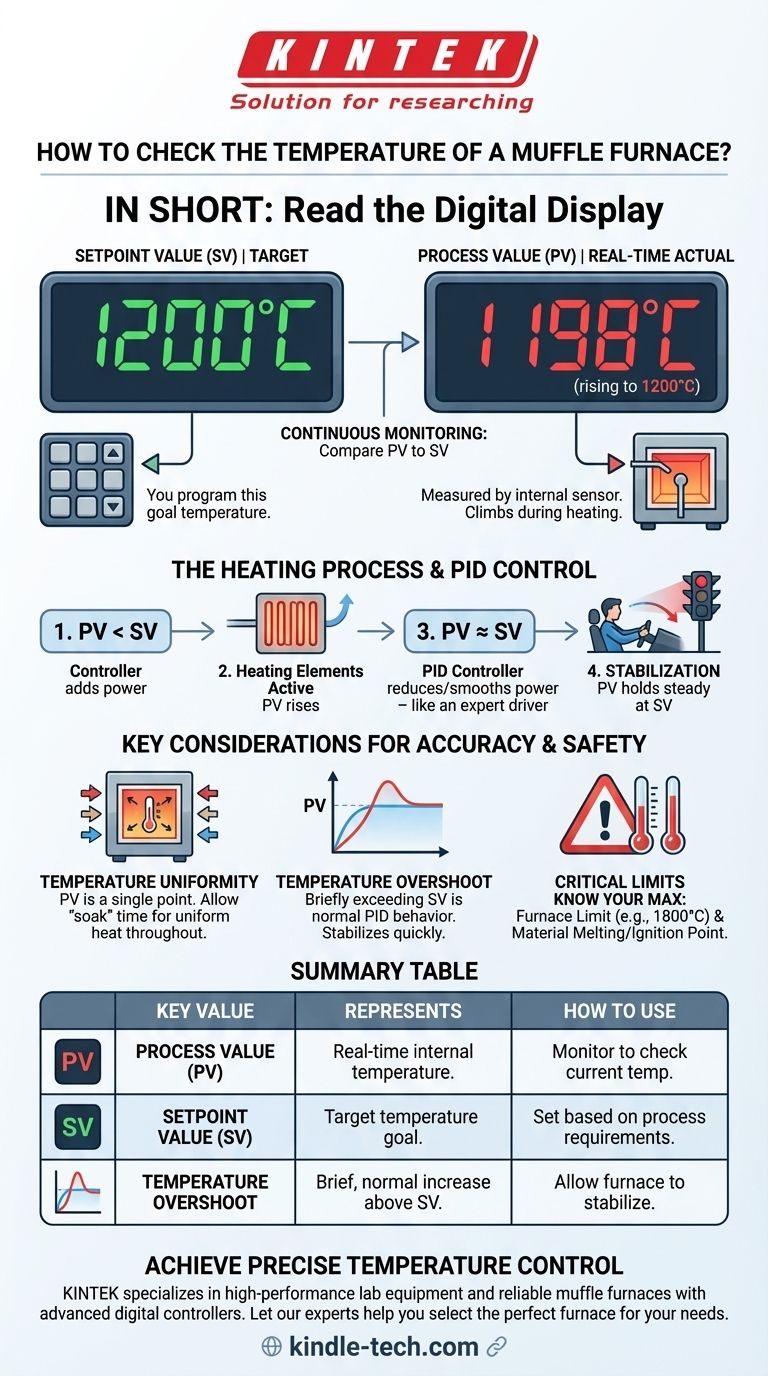

In short, you check the temperature of a muffle furnace by reading the digital display on its control panel. This display shows the real-time internal temperature, often labeled as "PV" (Process Value), which constantly updates as the furnace heats up or cools down. You compare this reading to your "SV" (Set Value), which is the target temperature you programmed.

The key is to understand that checking the temperature is not a single action, but a continuous process of monitoring the relationship between your target temperature (the setpoint) and the actual, real-time temperature reported by the furnace's internal sensor.

Decoding the Furnace Control Panel

Modern muffle furnaces use a digital controller to both manage and display temperature. Understanding the two primary values shown on this display is fundamental to correct operation.

The Setpoint Temperature (SV)

The Setpoint Value (SV) is your goal. This is the target temperature you instruct the furnace to reach and maintain for your specific process.

You program this value using the arrow keys or keypad on the control panel. On many controllers, this number is displayed in green.

The Process Temperature (PV)

The Process Value (PV) is the reality. This is the actual, real-time temperature measured by a sensor (typically a thermocouple) inside the furnace chamber.

This is the number you monitor to "check" the current temperature. It will climb during the heating phase, hold steady once stabilized, and fall during cooldown.

Observing the Heating Process

When you turn the furnace on, you will see the PV begin to rise toward the SV. This confirms the heating elements are working and the system is operating as expected. The rate of this increase depends on the furnace's power and size.

How a Muffle Furnace Controls Temperature

A muffle furnace doesn't just turn on and off like a simple oven. It uses a sophisticated feedback loop to achieve and maintain a precise temperature, ensuring stability for sensitive processes.

The Principle of Automatic Control

The furnace's "brain" is its controller, which constantly performs a simple comparison: Is the Process Value (PV) equal to the Setpoint Value (SV)?

If the PV is lower than the SV, the controller sends more power to the heating elements. If the PV is higher than the SV, it reduces or cuts power.

The Role of the Controller (PID)

This adjustment isn't just a crude on/off switch. Most modern furnaces use PID (Proportional-Integral-Derivative) control.

Think of it like an expert driver approaching a red light. Instead of slamming on the brakes at the last second, the driver (the controller) smoothly eases off the gas (the power) as they near the stop line (the setpoint) to avoid overshooting and ensure a stable, precise stop. This intelligent power management is what allows the furnace to hold a temperature with very high accuracy.

Understanding the Key Considerations

While operation is straightforward, awareness of a few key factors is critical for safety and achieving accurate results.

Temperature Uniformity

The displayed temperature (PV) is measured at a single point inside the furnace. The temperature may vary slightly in different areas of the chamber. For highly sensitive work, allow the furnace to "soak" or stabilize at the setpoint for a period to ensure the entire chamber reaches a uniform temperature.

Temperature Overshoot

It is normal for the PV to slightly exceed the SV for a brief moment before settling back down. This is called overshoot and is a natural characteristic of PID control systems. A well-tuned furnace will have minimal overshoot.

Critical Temperature Limits

Always be aware of two maximum temperatures:

- The Furnace Limit: Most muffle furnaces have a maximum operating temperature (e.g., 1800°C), which should never be exceeded.

- The Material Limit: More importantly, never set a temperature that exceeds the melting point or ignition point of the material you have placed inside the furnace.

Applying This to Your Work

Use these guidelines to ensure you are operating the furnace correctly for your specific goal.

- If your primary focus is a quick temperature check: Look for the Process Value (PV) on the digital display; this is the current internal temperature.

- If your primary focus is running a complete process: First, consult your procedural requirements to determine the correct target temperature, then use the control panel to program the Setpoint Value (SV) and monitor the PV until it stabilizes at that target.

- If your primary focus is safety and precision: Always cross-reference your setpoint with the known thermal limits of your sample material and allow the furnace time to soak at the target temperature to ensure uniformity.

By understanding the interplay between the setpoint and the process value, you can operate the muffle furnace with confidence and precision.

Summary Table:

| Key Temperature Value | What It Represents | How to Use It |

|---|---|---|

| Process Value (PV) | Real-time temperature measured by the internal sensor. | Monitor this to check the current furnace temperature. |

| Setpoint Value (SV) | The target temperature you program the furnace to reach. | Set this value based on your process requirements. |

| Temperature Overshoot | A brief, normal increase above the SV before stabilizing. | Allow the furnace to settle; this is part of the PID control process. |

Achieve precise and reliable temperature control in your lab.

Understanding your muffle furnace's temperature is critical for consistent results. KINTEK specializes in high-performance lab equipment, including reliable muffle furnaces with advanced digital controllers for superior accuracy and safety.

Let our experts help you select the perfect furnace for your specific application needs. Contact us today to discuss your requirements and ensure your processes run with maximum efficiency.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace used for? Achieve Precise High-Temperature Processing in Your Lab

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Lab's Needs

- Why is it important to hardening a steel? To Achieve Superior Strength and Wear Resistance

- What is the difference between a lab oven and a muffle furnace? A Guide to Temperature Applications

- What is the inside material of a muffle furnace? Choose the Right Lining for Your Application