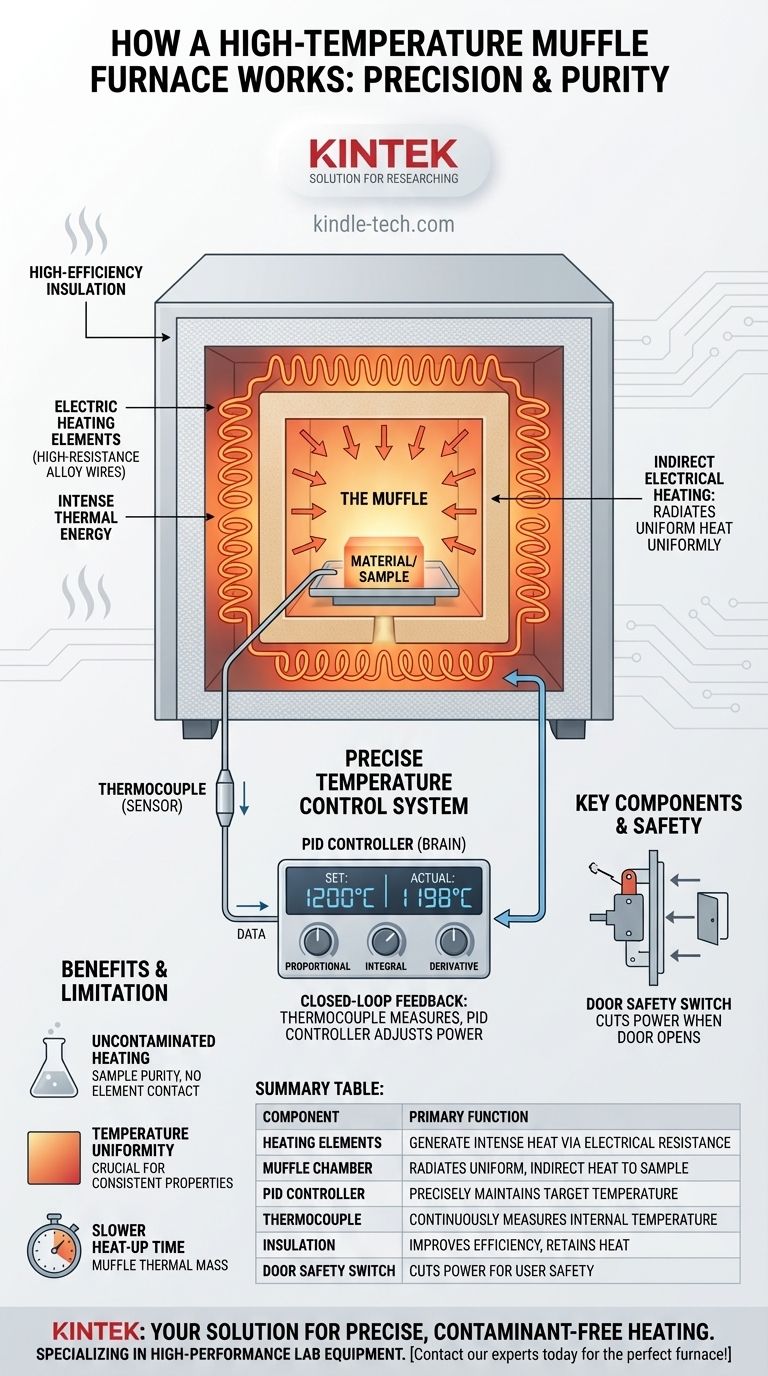

At its core, a high-temperature muffle furnace works by indirect electrical heating. It uses electric resistance elements to heat a separate, enclosed chamber—the "muffle"—which then radiates heat uniformly onto the material inside. This process is precisely managed by a digital control system to achieve and maintain specific high temperatures.

The defining principle of a modern muffle furnace is the separation of the heat source from the sample. This design ensures highly uniform, contaminant-free heating, which is crucial for sensitive laboratory and industrial processes.

The Core Principle: Indirect Heating Explained

The genius of the muffle furnace lies in its simple but effective method of heat transfer. It doesn't heat the sample directly; it heats the environment around it in a highly controlled way.

The Heating Elements: Generating the Heat

The process begins with electric heating elements, typically high-resistance alloy wires, located on the sides, back, or top of the furnace's internal structure.

When electricity passes through these elements, their high resistance causes them to become extremely hot, generating intense thermal energy.

The Muffle: The Heart of the Furnace

This thermal energy is not applied directly to your sample. Instead, it radiates inward and heats a separate, isolated chamber called the muffle.

This muffle, often made of a durable ceramic material, is designed to withstand extreme thermal stress and absorb heat evenly across its entire surface.

The Transfer of Energy

Once the muffle reaches the target temperature, it becomes the primary heat source for your sample. It radiates thermal energy uniformly from all sides, ensuring the object inside is heated evenly without any "hot spots" that could occur from direct exposure to a heating element.

How Temperature is Precisely Controlled

Reaching a high temperature is only half the battle; maintaining it is critical. Muffle furnaces use a sophisticated closed-loop feedback system to achieve exceptional temperature stability.

The Thermocouple: The Sensor

A thermocouple, a highly sensitive temperature sensor, is placed inside the heating chamber. Its sole job is to continuously measure the exact temperature within the muffle.

The PID Controller: The Brain

The thermocouple sends its real-time temperature data to a microprocessor known as a PID (Proportional-Integral-Derivative) controller.

This controller acts as the furnace's brain. It constantly compares the actual temperature (from the thermocouple) to the desired temperature you have set.

The Closed-Loop System in Action

If the temperature is too low, the PID controller increases the power sent to the heating elements. If the temperature is too high, it reduces or cuts the power.

This constant cycle of measuring, comparing, and adjusting allows the furnace to maintain a specific temperature with remarkable accuracy.

Key Components and Safety Features

A muffle furnace is more than just a hot box. Its design incorporates critical components for efficiency and safety.

High-Efficiency Insulation

The entire heating chamber is encased in layers of advanced insulating material. This prevents heat from escaping, which improves energy efficiency and allows the furnace to reach and maintain high temperatures more quickly.

The Door Safety Switch

Nearly all modern furnaces include a door safety switch. This mechanism immediately cuts power to the heating elements the moment the door is opened, protecting the user from exposure to extreme heat and preventing thermal shock to the heating elements.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs that are important to understand.

Benefit: Uncontaminated Heating

The single greatest advantage is sample purity. Because the material never comes into contact with the heating elements or byproducts of combustion (in fuel-fired versions), the risk of contamination is virtually eliminated.

Benefit: Temperature Uniformity

Heating via the muffle ensures a highly uniform thermal environment. This is critical for processes like annealing, ashing, or sintering, where consistent material properties are essential.

Limitation: Slower Heat-Up Time

Because the furnace must first heat the muffle, which then heats the sample, the overall heat-up time can be slower compared to direct heating methods. The muffle itself has thermal mass that needs to be overcome.

Making the Right Choice for Your Goal

Understanding how a muffle furnace operates allows you to leverage its strengths for your specific application.

- If your primary focus is material purity and precision: The muffle's indirect heating is its most valuable feature, shielding your sample from direct element contact and ensuring a clean environment.

- If your primary focus is process repeatability: Rely on the PID controller. Its ability to execute and hold precise temperature profiles ensures you get consistent results from one run to the next.

- If your primary focus is operational safety: Always confirm the door switch is functional and trust the PID controller's display as the definitive reading of the internal chamber temperature.

Ultimately, the muffle furnace is a purpose-built tool designed for control, uniformity, and purity in high-temperature applications.

Summary Table:

| Component | Primary Function |

|---|---|

| Heating Elements | Generate intense heat via electrical resistance. |

| Muffle Chamber | Radiates uniform, indirect heat to the sample. |

| PID Controller | Precisely maintains the target temperature. |

| Thermocouple | Continuously measures the internal temperature. |

| Insulation | Improves efficiency by retaining heat. |

| Door Safety Switch | Cuts power when the door is opened for user safety. |

Ready to achieve precise, contaminant-free heating in your lab?

KINTEK specializes in high-performance lab equipment, including a range of reliable muffle furnaces designed for accuracy, safety, and repeatability. Whether your application requires material purity, process repeatability, or operational safety, our solutions are built to meet your specific laboratory needs.

Contact our experts today to find the perfect furnace for your application and enhance your lab's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the advantages of using a precision furnace for SrFeO3 synthesis? Low-Temp Efficiency and Nanoscale Control

- What is the maximum temperature of muffle furnace? A Guide from 1100°C to 1800°C

- What role does a high-temperature muffle furnace play in Cu-TiO2 thin films? Achieve Precise Phase Transformation

- How can residual mold release wax be removed from alloy compacts? Essential Furnace Debinding Steps for Purity

- How is a box resistance furnace applied in Ti2AlN/TiN oxidation study? Simulate High-Temp Durability

- How are high-temperature heating devices like muffle furnaces used in the preparation of silica powder? Expert Guide

- What is the function of industrial box resistance furnaces in 3D printing post-processing? Optimize Metal AM Parts

- Why is a calcination furnace operated at 900°C for radioactive waste? Ensure Total Organic Destruction & Stability