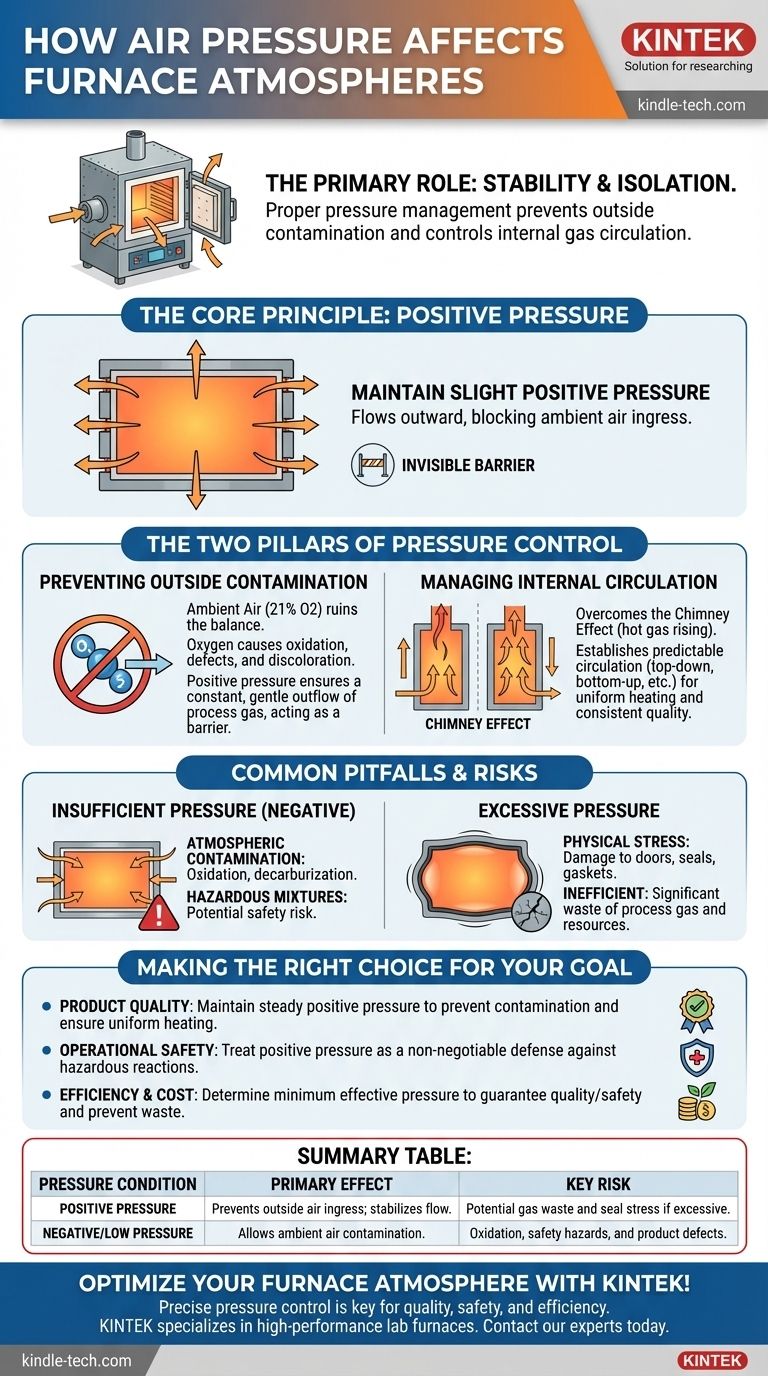

The primary role of air pressure is to create a stable and isolated environment inside a furnace. Proper pressure management prevents contamination from the outside atmosphere and controls the internal circulation of gases, ensuring both the quality of the product and the safety of the operation.

The core principle is maintaining a slight positive pressure within the furnace. This ensures that the controlled atmosphere flows outward through any potential leaks, effectively blocking ambient air from entering and disrupting the process.

The Two Pillars of Pressure Control

To understand why pressure is so critical, we need to look at the two main problems it solves: contamination from the outside and instability on the inside.

Preventing Contamination from Outside Air

A furnace with a controlled atmosphere is a carefully balanced chemical environment. The introduction of uncontrolled ambient air can ruin that balance.

Ambient air is roughly 21% oxygen. If this oxygen leaks into a high-temperature heating chamber, it can cause unwanted oxidation on the surface of the parts, leading to defects, discoloration, or failed metallurgical properties.

Maintaining a slight positive pressure ensures a constant, gentle outflow of the process gas. This acts as an invisible barrier, preventing any oxygen-rich air from seeping in through seals, doors, or other connection points.

Managing Internal Atmosphere Circulation

A significant temperature difference exists between the hot atmosphere inside the furnace and the cooler air outside. This creates a natural phenomenon known as the chimney effect.

The hot, less-dense gas inside the furnace wants to rise, creating buoyancy and unpredictable convection currents. If not managed, this effect can lead to uneven heating and inconsistent product quality.

By actively managing gas flow and pressure, you can overcome the chimney effect and establish a predictable circulation pattern, whether it's top-down, bottom-up, or horizontal, ensuring every part is exposed to the same conditions.

Common Pitfalls and Risks

Failing to manage furnace pressure introduces significant risks that compromise both the final product and the safety of the equipment.

The Risk of Insufficient Pressure

When the internal pressure is too low (or negative), the furnace becomes vulnerable to leaks. This is the most common failure mode.

The immediate result is atmospheric contamination. This can lead to oxidation, decarburization, or other undesirable surface reactions that render the processed parts unusable.

In some cases, the introduction of ambient air into a hot, gas-rich environment can create a potentially hazardous or explosive mixture.

The Problem with Excessive Pressure

While positive pressure is necessary, too much of it creates its own problems.

Excessive internal pressure puts unnecessary physical stress on the furnace structure, particularly on doors, seals, and gaskets, leading to premature wear and potential damage.

It is also highly inefficient. Pushing too much process gas through the system to maintain high pressure is a significant waste of resources and increases operational costs. The goal is to find the minimum effective pressure that guarantees a stable environment.

Making the Right Choice for Your Goal

Achieving a stable furnace atmosphere requires balancing your objectives. Your pressure strategy should be directly tied to your primary operational goal.

- If your primary focus is product quality: Maintain a steady, consistent positive pressure to prevent any level of atmospheric contamination and ensure uniform heating by overcoming the chimney effect.

- If your primary focus is operational safety: Treat positive pressure as your non-negotiable first line of defense against hazardous reactions caused by ambient air leaking into a controlled atmosphere.

- If your primary focus is efficiency and cost: Systematically determine the minimum effective pressure that still guarantees part quality and safety, thereby preventing the unnecessary waste of expensive process gases.

Ultimately, mastering air pressure is about taking control of the furnace's internal environment to deliver predictable and safe results.

Summary Table:

| Pressure Condition | Primary Effect | Key Risk |

|---|---|---|

| Positive Pressure | Prevents outside air ingress; stabilizes internal gas flow. | Potential gas waste and seal stress if excessive. |

| Negative/Low Pressure | Allows ambient air contamination. | Oxidation, safety hazards, and product defects. |

Optimize your furnace atmosphere for superior results with KINTEK!

Whether you're focused on product quality, operational safety, or cost efficiency, precise pressure control is key. KINTEK specializes in high-performance lab furnaces and consumables designed to deliver consistent, contamination-free heating for your most critical processes.

Contact our experts today to discuss how our solutions can enhance your laboratory's performance and reliability.

Visual Guide

Related Products

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the working mechanism of a high-purity hydrogen atmosphere furnace? Master Tungsten Sintering Efficiency

- What is the core function of a high-temperature atmosphere sintering furnace in the fabrication of Ni-Al2O3-TiO2 composites?

- What is a controlled atmosphere lab furnace? Master Material Protection and Transformation

- Why Use an Atmosphere Protection Furnace with Argon for FM Steel? Ensure Integrity and Prevent Oxidation

- Why use a tube atmosphere furnace with inert gas for catalyst calcination? Protect Active Sites from Contamination

- How does a high-temperature atmosphere furnace contribute to AlN/Si3N4 substrates? Unlock Superior Thermal Conductivity

- How does a high-temperature atmosphere furnace study point defect equilibrium? Control ZrO2/Cr2O3 Interface Potentials

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results