At its core, an Inductotherm furnace works by using a powerful, controlled magnetic field to make metal heat and melt itself from the inside out. This process, known as electromagnetic induction, bypasses the need for external flames or heating elements. Instead, an alternating electric current flows through a copper coil, generating a magnetic field that induces electrical currents directly within the conductive metal, causing it to heat rapidly due to its own internal resistance.

The fundamental advantage of induction technology is its ability to generate heat directly within the material being melted. This avoids the inefficiencies of conventional heating methods, resulting in faster melting, higher purity, and more precise temperature control.

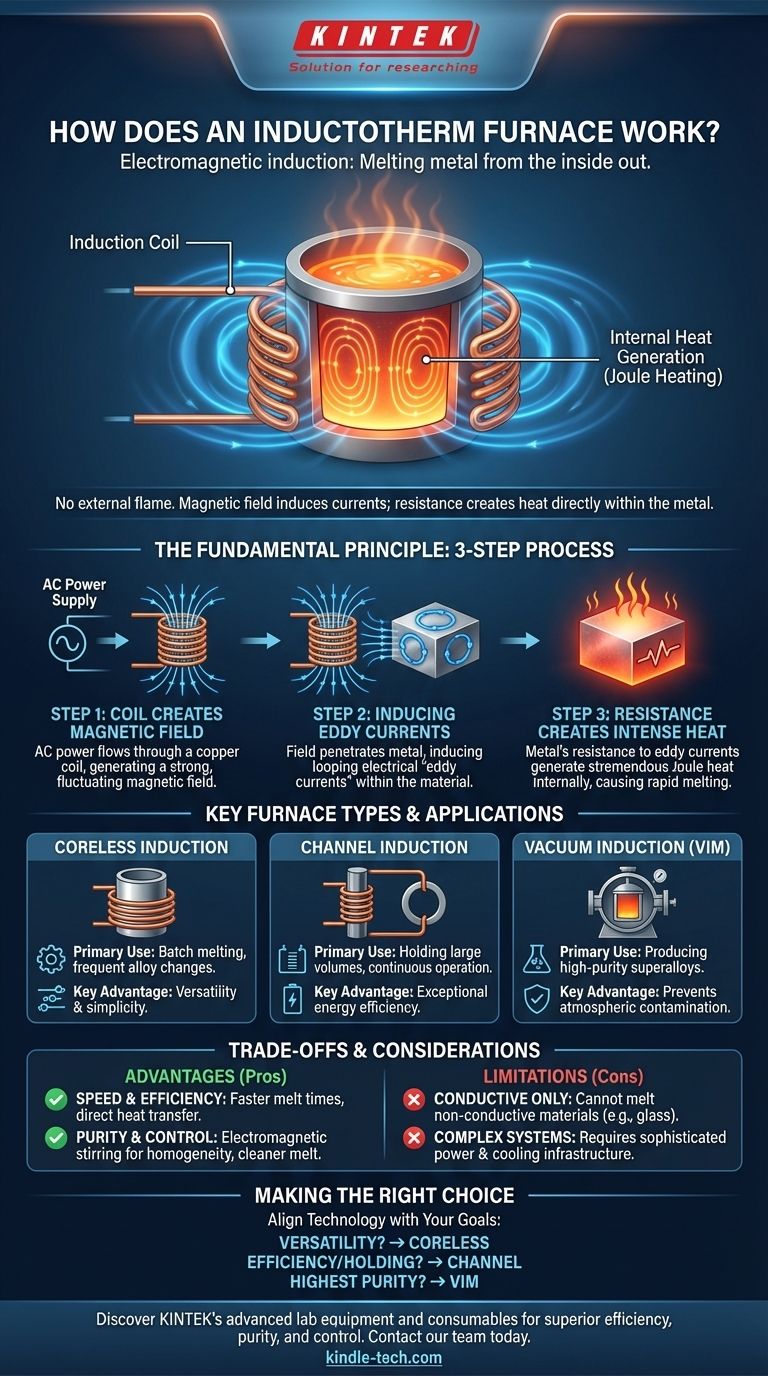

The Fundamental Principle: Turning Magnetism into Heat

Understanding how an induction furnace operates requires grasping a three-step sequence that converts electrical energy into thermal energy with remarkable efficiency.

Step 1: The Induction Coil Creates a Magnetic Field

The process begins with a specialized power supply that converts standard utility power into a high-current, alternating current (AC) at a specific frequency. This current is sent through a multi-turn copper coil that surrounds the crucible holding the metal charge. The flow of AC through this coil generates a strong, rapidly fluctuating magnetic field in the space within the coil.

Step 2: Inducing "Eddy Currents" in the Metal

This alternating magnetic field penetrates the conductive metal placed inside the crucible. According to Faraday's Law of Induction, the fluctuating magnetic field induces looping electrical currents within the metal. These circular flows of electricity are known as eddy currents.

Step 3: Resistance Creates Intense Heat

The metal has a natural resistance to the flow of these induced eddy currents. As the eddy currents circulate against this resistance, they generate tremendous heat through a principle known as Joule heating. This heat is produced inside the metal itself, causing it to heat and melt uniformly and quickly.

A Closer Look at the Key Furnace Types

While the core principle remains the same, induction furnaces are engineered into different configurations to suit specific industrial applications.

The Coreless Induction Furnace

This is the most common design. It consists of a refractory-lined crucible that is directly surrounded by the induction coil. Its simple, robust design makes it extremely versatile for melting a wide range of metals and alloys in batches, from iron and steel to copper and aluminum.

The Channel (or Core-Type) Induction Furnace

This design operates more like a transformer. The induction coil is wound around an iron core, which is linked to a closed loop or "channel" of molten metal. The molten metal loop acts as the secondary coil of the transformer. Heat generated in this loop causes the metal to circulate into the main furnace bath, providing excellent stirring. These furnaces are exceptionally efficient and are primarily used for holding large volumes of a single molten alloy at a constant temperature.

The Vacuum Induction Melting (VIM) Furnace

A VIM furnace is a specialized coreless furnace housed within a vacuum-tight chamber. By melting metal in a vacuum, it prevents the molten charge from reacting with oxygen, nitrogen, and other atmospheric gases. This is essential for producing high-purity, "clean" superalloys required for critical applications in the aerospace, medical, and power generation industries.

Understanding the Trade-offs and Considerations

No technology is a universal solution. Induction heating offers clear advantages but also comes with specific limitations.

Advantage: Speed and Efficiency

Because heat is generated internally, melt times are significantly shorter than in fuel-fired furnaces. Energy is transferred directly to the metal with minimal heat loss to the surrounding environment, making the process highly energy-efficient.

Advantage: Purity and Control

The electromagnetic field creates a natural stirring action in the molten bath, ensuring a homogenous mixture and consistent alloy composition. The absence of combustion byproducts also results in a cleaner melt. VIM furnaces take this purity to the highest possible level.

Limitation: Conductive Materials Only

The working principle relies entirely on inducing currents in the material. Therefore, induction furnaces cannot be used to melt non-conductive materials like glass or ceramics.

Limitation: Sophisticated Power and Cooling Systems

The power supply units that create the necessary high-current AC are complex and represent a significant capital investment. Furthermore, the induction coil itself must be water-cooled to dissipate waste heat, adding another layer of operational complexity.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on your operational and metallurgical goals.

- If your primary focus is versatility and frequent alloy changes: A coreless induction furnace is the industry standard for foundries that need to produce various metals in distinct batches.

- If your primary focus is holding large volumes of molten metal efficiently: A channel induction furnace offers superior efficiency for continuous operation and maintaining a single alloy's temperature.

- If your primary focus is producing the highest purity alloys for critical applications: A vacuum induction melting (VIM) furnace is the only suitable choice to prevent atmospheric contamination.

By understanding this core principle of electromagnetic heating, you can align the right technology with your specific production goals.

Summary Table:

| Furnace Type | Primary Use Case | Key Advantage |

|---|---|---|

| Coreless Induction | Batch melting, frequent alloy changes | Versatility and simplicity |

| Channel Induction | Holding large volumes of a single alloy | Exceptional energy efficiency |

| Vacuum Induction (VIM) | Producing high-purity superalloys | Prevents atmospheric contamination |

Ready to select the right induction furnace for your metal melting needs?

KINTEK specializes in providing advanced lab equipment and consumables for laboratory and industrial applications. Whether you require a versatile coreless furnace, an efficient channel furnace for holding, or a high-purity VIM furnace for critical alloys, our experts can help you find the perfect solution for superior efficiency, purity, and control.

Contact our team today to discuss your specific requirements and discover how KINTEK can enhance your melting operations.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity