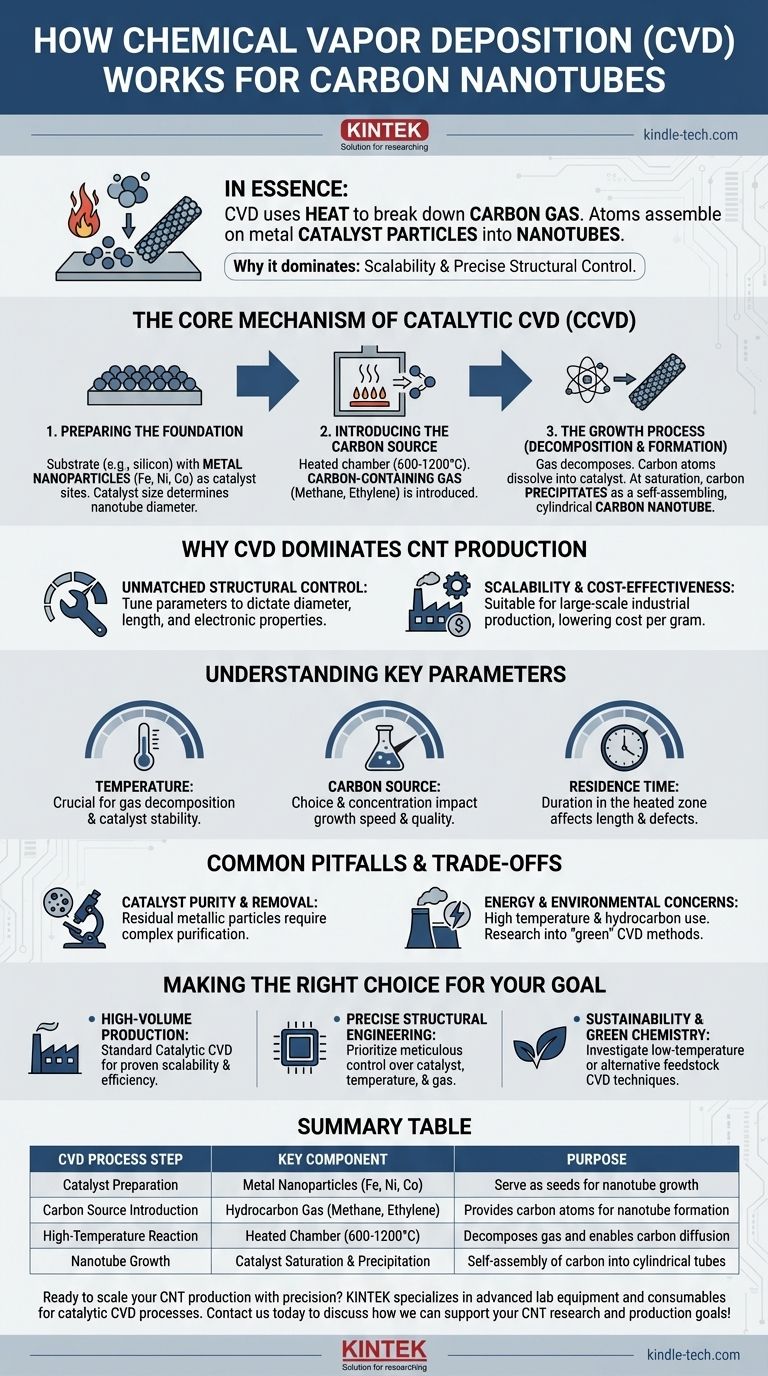

In essence, chemical vapor deposition (CVD) for carbon nanotubes works by using heat to break down a carbon-containing gas. In a high-temperature reaction chamber, these carbon atoms land on a surface prepared with tiny metal catalyst particles. These catalyst particles act as "seeds," assembling the carbon atoms into the unique, cylindrical structure of a nanotube.

The core reason CVD dominates carbon nanotube production is its unique combination of scalability and precise structural control. It allows for the cost-effective, large-scale synthesis of nanotubes with specific, engineered properties that other methods cannot easily achieve.

The Core Mechanism of Catalytic CVD (CCVD)

To understand how carbon nanotubes (CNTs) are grown, we must look at the specific variant used for their production: catalytic chemical vapor deposition, or CCVD. The catalyst is not just an additive; it is the engine of the growth process.

Step 1: Preparing the Foundation (The Catalyst)

The process begins not with carbon, but with a substrate (like silicon or quartz) coated with a thin layer of metallic nanoparticles.

These nanoparticles, typically iron, nickel, or cobalt, serve as the catalyst sites. The size of these particles is critical, as it directly influences the diameter of the nanotubes that will grow from them.

Step 2: Introducing the Carbon Source

The prepared substrate is placed inside a reaction chamber and heated to a high temperature, often between 600°C and 1200°C.

A carbon-containing gas, such as methane, ethylene, or acetylene, is then introduced into the chamber. This gas is known as the carbon feedstock or precursor.

Step 3: The Growth Process (Decomposition and Formation)

At these high temperatures, the hydrocarbon gas molecules break apart, or "decompose." This releases individual carbon atoms.

These carbon atoms diffuse towards and dissolve into the metal catalyst particles. The catalyst particle quickly becomes saturated with carbon.

To regain a stable state, the catalyst "precipitates" the excess carbon out. Because of the specific crystalline interaction between the carbon and the metal catalyst, the carbon atoms emerge in a self-assembling, cylindrical lattice—forming the hollow tube structure of a carbon nanotube.

Why CVD Dominates CNT Production

While older methods like laser ablation and arc discharge can produce high-quality CNTs, they are difficult to scale. CVD has become the commercial standard for clear and practical reasons.

Unmatched Structural Control

The single greatest advantage of CVD is controllability. By carefully tuning the process parameters, operators can dictate the final properties of the nanotubes.

This includes controlling their diameter (by changing catalyst particle size), length (by adjusting growth time), and even their electronic properties (chirality).

Scalability and Cost-Effectiveness

Unlike the extreme conditions required for laser ablation or arc discharge, CVD operates under more manageable temperatures and pressures.

This makes the process far more suitable for continuous, large-scale industrial production, significantly lowering the cost per gram of nanotubes and enabling their use in commercial products.

Understanding the Key Parameters

The success of any CVD process for CNTs depends on the precise management of three critical operating parameters.

The Role of Temperature

Temperature is arguably the most important variable. It must be high enough to decompose the carbon source gas but not so high that it damages the catalyst or produces unwanted amorphous carbon byproducts.

The Impact of Carbon Source

The choice and concentration of the carbon gas are crucial. Different gases decompose at different rates and temperatures, which directly impacts the growth speed and structural quality of the nanotubes.

The Importance of Residence Time

Residence time refers to how long the carbon gas stays within the heated reaction zone. A longer residence time can lead to longer nanotubes, but too long can also increase the formation of defects and impurities.

Common Pitfalls and Trade-offs

Despite its advantages, the CVD process is not without challenges that require careful management.

Catalyst Purity and Removal

A common issue is that residual catalyst particles can remain embedded in or attached to the nanotubes after growth.

This contamination can negatively affect the material's properties and often necessitates a complex, multi-step purification process to remove the metallic impurities.

Energy and Environmental Concerns

The high temperatures required for CVD make it an energy-intensive process. This energy consumption, along with the use of hydrocarbon gases, contributes to its environmental footprint.

Current research is heavily focused on developing "green" CVD methods, using lower temperatures or alternative feedstocks like captured CO2 and pyrolyzed methane to reduce ecotoxicity.

Making the Right Choice for Your Goal

Understanding the fundamentals of the CVD process allows you to align your production strategy with your final objective.

- If your primary focus is high-volume, cost-effective production: Standard catalytic CVD is the definitive industrial choice due to its proven scalability and efficiency.

- If your primary focus is precise structural engineering for electronics: You must prioritize meticulous control over catalyst particle size, temperature, and gas flow to achieve the desired nanotube properties.

- If your primary focus is sustainability and green chemistry: Investigate emerging low-temperature CVD techniques or those that utilize waste or captured carbon feedstocks to minimize environmental impact.

Mastering the interplay of catalyst, carbon, and heat is the key to unlocking the full potential of carbon nanotubes for the next generation of advanced materials.

Summary Table:

| CVD Process Step | Key Component | Purpose |

|---|---|---|

| Catalyst Preparation | Metal Nanoparticles (Fe, Ni, Co) | Serve as seeds for nanotube growth |

| Carbon Source Introduction | Hydrocarbon Gas (Methane, Ethylene) | Provides carbon atoms for nanotube formation |

| High-Temperature Reaction | Heated Chamber (600-1200°C) | Decomposes gas and enables carbon diffusion |

| Nanotube Growth | Catalyst Saturation & Precipitation | Self-assembly of carbon into cylindrical tubes |

Ready to scale your carbon nanotube production with precision? KINTEK specializes in advanced lab equipment and consumables for catalytic CVD processes. Whether you're focused on high-volume synthesis, precise structural control, or sustainable green chemistry methods, our expertise and solutions are tailored to meet your laboratory's unique challenges. Contact us today to discuss how we can support your CNT research and production goals!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating