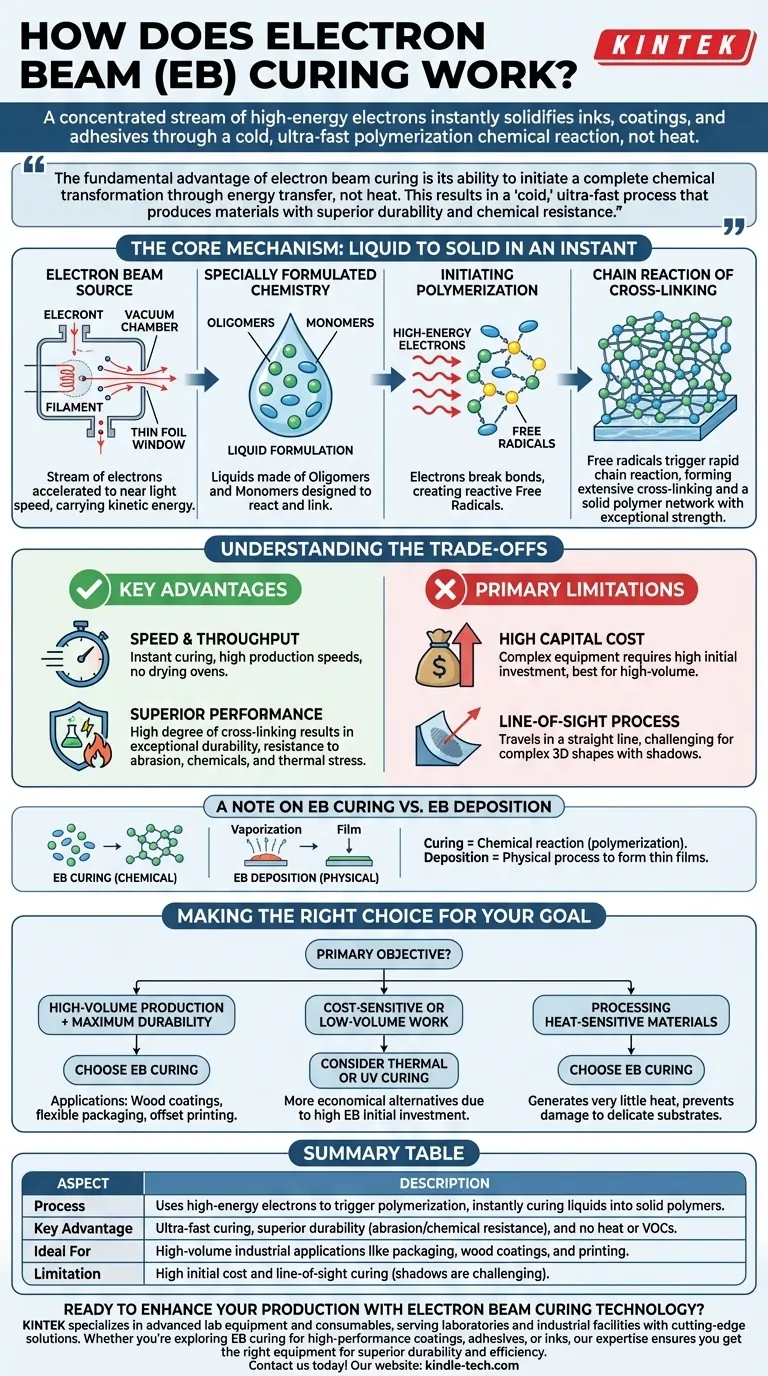

At its core, electron beam (EB) curing is a process that uses a concentrated stream of high-energy electrons to instantly solidify specially formulated liquids like inks, coatings, and adhesives. Unlike traditional methods that rely on heat to evaporate solvents, EB curing triggers a rapid chemical reaction called polymerization. This reaction transforms the liquid into a durable, solid polymer network almost instantaneously, without the need for high temperatures or volatile organic compounds (VOCs).

The fundamental advantage of electron beam curing is its ability to initiate a complete chemical transformation through energy transfer, not heat. This results in a "cold," ultra-fast process that produces materials with superior durability and chemical resistance.

The Core Mechanism: From Liquid to Solid in an Instant

To understand how EB curing works, it's essential to break down the process into its key components: the energy source, the material chemistry, and the resulting reaction. This is not a heating or drying process; it is a fundamental chemical change at the molecular level.

What is an Electron Beam?

An electron beam is a stream of electrons accelerated to very high speeds, typically close to the speed of light, within a vacuum chamber. This beam is then directed out of the chamber through a thin foil window onto the material being treated.

Each electron carries a significant amount of kinetic energy. It is this energy, not heat, that drives the curing reaction.

The Specially Formulated Chemistry

EB curing does not work on standard paints or glues. It requires liquids made of two primary components: oligomers and monomers.

These are relatively small molecules that act as the building blocks for the final solid polymer. When exposed to the electron beam, they are designed to react and link together.

Initiating Polymerization

When the high-energy electrons from the beam strike the liquid formulation, they transfer their energy to the oligomer and monomer molecules. This energy transfer breaks chemical bonds, creating highly reactive species known as free radicals.

The creation of these free radicals is the critical first step that initiates the entire curing process.

The Chain Reaction of Cross-Linking

Once free radicals are formed, they trigger an extremely fast chain reaction. Each free radical attacks a neighboring monomer or oligomer, linking to it and creating a new, larger free radical in the process.

This repeats thousands of times in a fraction of a second, creating long, interconnected polymer chains. This extensive, three-dimensional bonding is called cross-linking, which is responsible for the final material's exceptional strength and stability.

Understanding the Trade-offs

While powerful, electron beam curing is a specialized technology with a distinct set of advantages and limitations. It is not a universal solution, and its suitability depends entirely on the application's specific requirements.

Key Advantage: Speed and Throughput

The curing reaction is nearly instantaneous. This allows for incredibly high production speeds, as materials are fully cured the moment they pass under the beam. There is no need for long drying ovens or cool-down periods.

Key Advantage: Superior Performance

The high degree of cross-linking achieved with EB curing results in a finish with exceptional durability. These surfaces are highly resistant to abrasion, chemicals, and thermal stress, making them suitable for demanding industrial and commercial applications.

Primary Limitation: High Capital Cost

The equipment required to generate and safely shield an electron beam is complex and expensive. This high initial investment is the most significant barrier to adoption and is typically only justifiable for high-volume manufacturing operations.

Primary Limitation: Line-of-Sight Process

The electron beam travels in a straight line. Therefore, it can only cure surfaces that are directly exposed to the beam. Curing complex, three-dimensional shapes with shadowed areas can be challenging or impossible without sophisticated part-handling systems.

A Note on Electron Beam Deposition

It is crucial not to confuse EB curing with electron beam deposition. While both use an electron beam, their purpose is different. Curing initiates a chemical reaction (polymerization). Deposition is a physical process used to vaporize a solid material, which then condenses onto a surface to form a thin film coating.

Making the Right Choice for Your Goal

Selecting the right curing technology requires a clear understanding of your project's primary objective, from production volume to end-use performance requirements.

- If your primary focus is high-volume production with maximum durability: EB curing is a leading choice for applications like industrial wood coatings, high-performance flexible packaging, and offset printing.

- If your primary focus is cost-sensitive or low-volume work: The high initial investment for EB systems makes traditional thermal curing or even UV curing more practical and economical alternatives.

- If your primary focus is processing heat-sensitive materials: EB curing is an excellent solution, as it generates very little heat, preventing damage to delicate substrates like thin plastic films or paper.

Ultimately, electron beam curing is a powerful tool for achieving unmatched performance and speed in applications where the initial investment can be justified by the final product's quality and the efficiency of the manufacturing process.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Uses high-energy electrons to trigger polymerization, instantly curing liquids into solid polymers. |

| Key Advantage | Ultra-fast curing, superior durability (abrasion/chemical resistance), and no heat or VOCs. |

| Ideal For | High-volume industrial applications like packaging, wood coatings, and printing. |

| Limitation | High initial cost and line-of-sight curing (shadows are challenging). |

Ready to enhance your production with electron beam curing technology?

KINTEK specializes in advanced lab equipment and consumables, serving laboratories and industrial facilities with cutting-edge solutions. Whether you're exploring EB curing for high-performance coatings, adhesives, or inks, our expertise ensures you get the right equipment for superior durability and efficiency.

Contact us today to discuss how we can support your specific needs and help you achieve faster, more reliable curing results!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Small Injection Molding Machine for Lab Use

People Also Ask

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How is diamond coating made? A Guide to CVD and PVD Methods

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation