At its core, freeze-drying benefits the cosmetics industry by removing water—the primary catalyst for ingredient degradation and microbial growth. This process, known as lyophilization, allows for the creation of highly stable, potent, and preservative-free products that remain inert until the moment of use, dramatically extending shelf life and preserving the efficacy of sensitive active ingredients.

The central challenge in modern cosmetics is delivering potent, active ingredients without them degrading on the shelf. Freeze-drying solves this by putting the formula into a state of suspended animation, preserving its full power until it is rehydrated by the consumer.

The Core Problem Freeze-Drying Solves: Ingredient Instability

Why Water is a Double-Edged Sword

Water is essential for life, but in a cosmetic formula, it is also the medium where most undesirable reactions occur. It enables the oxidation of antioxidants, the breakdown of sensitive molecules, and the growth of bacteria, mold, and yeast.

Traditionally, formulators combat this by adding preservatives, which many consumers now seek to avoid.

The Vulnerability of Active Ingredients

High-performance ingredients are often the most fragile. Actives like Vitamin C (L-Ascorbic Acid), retinoids, peptides, and certain plant extracts are notoriously unstable in water-based serums and creams, losing their potency long before the product is finished.

This forces manufacturers to either use less effective but more stable derivatives or accept that the product's efficacy will decline significantly over time.

The Traditional Solution and Its Drawbacks

Besides preservatives, brands have relied on airtight packaging, opaque bottles, and lower concentrations of actives to slow degradation. These are compromises that mitigate the problem but do not solve it at the source.

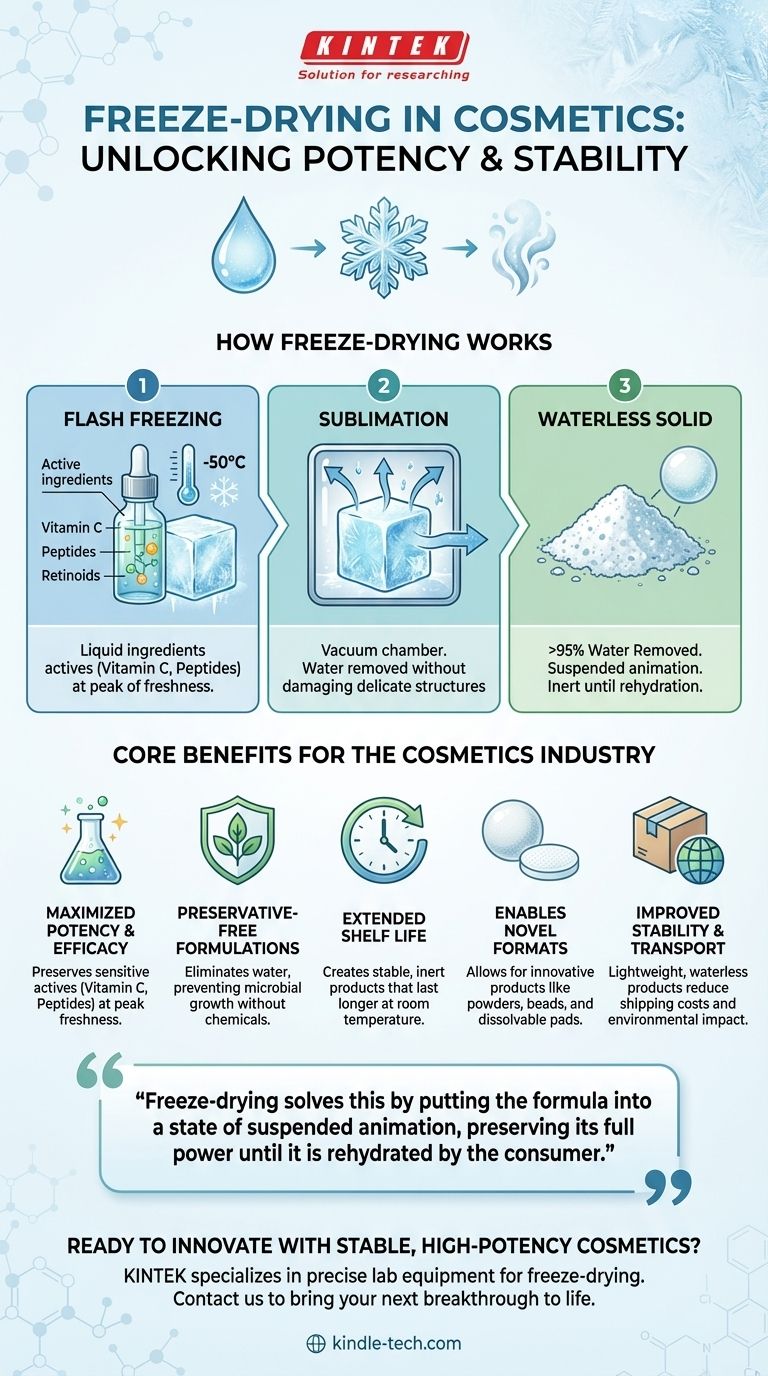

How Freeze-Drying Works in Cosmetics

Step 1: Flash Freezing the Formulation

The process begins by taking a liquid cosmetic formula—often a potent serum or treatment—and rapidly freezing it at a very low temperature. This locks all the ingredients, including the delicate actives, into a fixed, solid state.

Step 2: Removing Water via Sublimation

The frozen product is then placed in a strong vacuum. The pressure is lowered to a point where the frozen water transitions directly from a solid (ice) to a gas (water vapor), completely bypassing the liquid phase. This gentle process is called sublimation.

Because the water is never in a liquid state, it doesn't disturb the structure of the active ingredients, preserving them perfectly.

The Result: A Potent, Waterless Solid

The final product is a lightweight, porous solid, often in the form of a powder, bead, or wafer. With over 95% of the water removed, the active ingredients are left in a state of suspended animation, safe from oxidation and microbial growth.

Understanding the Key Benefits

Maximizing Potency and Efficacy

Freeze-drying preserves ingredients at their peak freshness. When the consumer rehydrates the product with water or a specified activator, they are using a formula that is as potent as the day it was made.

Creating Preservative-Free Formulations

By removing water, freeze-drying eliminates the primary condition required for microbial growth. This allows for the creation of "clean," preservative-free products with an exceptionally long shelf life at room temperature.

Enabling Novel Product Formats

This technology opens the door to innovative textures and application rituals. Products can be sold as single-use powder spheres or dissolvable pads, creating a unique and engaging experience for the user who participates in the "activation" of their skincare.

Enhancing Transport and Stability

Waterless products are significantly lighter, reducing shipping costs and environmental impact. They are also far less susceptible to damage from temperature changes during transport and storage.

Making the Right Choice for Your Goal

When considering this technology, it's vital to align its benefits with your primary objective.

- If your primary focus is maximum potency for active ingredients: Freeze-drying is the gold standard for preserving sensitive molecules like pure Vitamin C or growth factors until the moment of use.

- If your primary focus is creating "clean beauty" products: This is one of the most effective methods for ensuring product stability and safety without relying on traditional chemical preservatives.

- If your primary focus is product innovation and user experience: Freeze-dried formats offer a unique, tactile application process that signals freshness and high-tech efficacy to the consumer.

Ultimately, freeze-drying empowers formulators to deliver on the promise of high-potency, stable cosmetics that meet the demands of the modern, informed consumer.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Maximizes Potency | Preserves sensitive actives like Vitamin C & peptides at peak efficacy. |

| Enables Preservative-Free Formulas | Eliminates water, preventing microbial growth without chemicals. |

| Extends Shelf Life | Creates stable, inert products that last longer at room temperature. |

| Enables Novel Formats | Allows for innovative products like powders, beads, and dissolvable pads. |

| Improves Stability & Transport | Lightweight, waterless products reduce shipping costs and environmental impact. |

Ready to innovate with stable, high-potency cosmetics?

KINTEK specializes in providing the precise lab equipment and consumables needed for advanced freeze-drying (lyophilization) processes. Whether you're developing preservative-free serums, potent actives, or novel product formats, our solutions help you achieve superior stability and efficacy.

Contact us today to discuss how we can support your cosmetic formulation goals and bring your next breakthrough product to life.

Get in touch with our experts now!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the three main stages of the freeze-drying process? Master Sublimation and Desorption

- What are some common drying methods used in laboratories and their drawbacks? Choose the Right Method to Protect Your Samples

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- How does laboratory freeze drying work to preserve biological products? The Ultimate Guide to Lyophilization

- What types of products can be freeze dried? From Food to Pharmaceuticals and Beyond