At its core, heat treatment is a controlled process of heating and cooling a metal to fundamentally alter its internal crystal structure. This manipulation allows you to change its mechanical properties, tailoring them for a specific purpose by adjusting characteristics like hardness, toughness, and ductility.

Heat treatment is not about making a metal universally "better." It is a strategic process of making targeted trade-offs, often sacrificing one property (like softness) to gain another (like hardness) to meet the precise performance demands of an application.

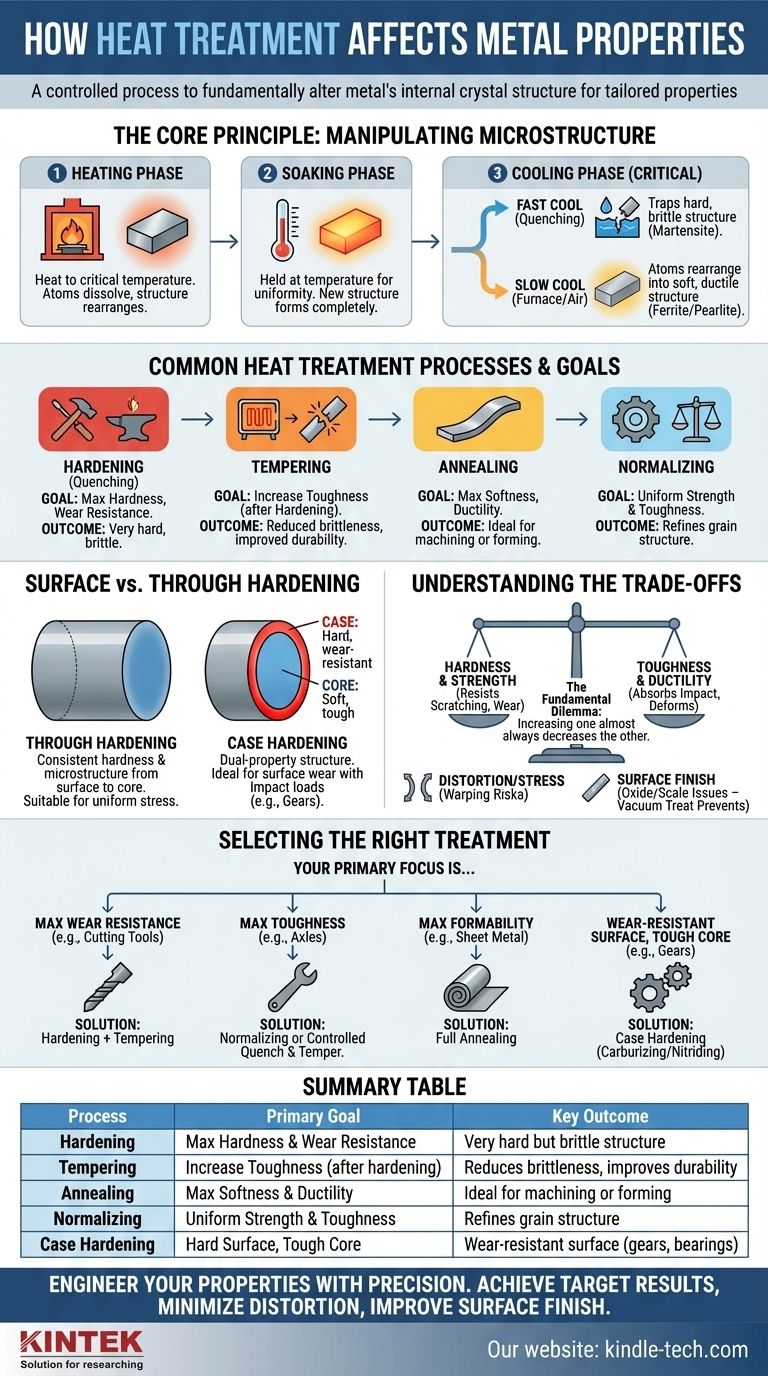

The Core Principle: Manipulating Metal's Microstructure

Heat treatment works by changing the physical arrangement and size of the crystals, or "grains," within a metal. Think of it as re-organizing the metal's internal building blocks to create a new structure with different properties.

The Heating Phase

The first step is to heat the metal to a specific, critical temperature. This gives the atoms enough energy to dissolve elements and rearrange themselves into a different crystal structure, most commonly a structure known as austenite in steels.

The Soaking Phase

Once at the target temperature, the metal is held, or "soaked," for a set amount of time. This ensures the entire part reaches a uniform temperature and that the new crystal structure has formed completely throughout the material.

The Cooling Phase (The Critical Step)

The rate at which the metal is cooled from its soaking temperature is the most critical factor determining its final properties. The speed of the cooling "locks in" a specific microstructure.

A fast cool (quenching), often in water, oil, or forced air, traps a very hard and brittle structure called martensite.

A slow cool, such as letting the part cool in the furnace or in still air, allows the atoms to rearrange into softer, more ductile structures like ferrite and pearlite.

Common Heat Treatment Processes & Their Goals

Different combinations of heating, soaking, and cooling are used to achieve specific outcomes.

Hardening (Quenching)

This process is used to maximize the hardness and wear resistance of a metal. It involves heating the material and then rapidly cooling (quenching) it. The result is a part that is very hard but also brittle.

Tempering

Tempering is almost always performed after hardening. The brittle, hardened part is reheated to a lower temperature to relieve internal stresses and restore a degree of toughness. This makes the part more durable and less likely to shatter, though it slightly reduces its peak hardness.

Annealing

The goal of annealing is to make a metal as soft and ductile as possible. This is achieved by heating the metal and then cooling it very slowly, often by leaving it inside the turned-off furnace. This is ideal for parts that need to be extensively machined or formed.

Normalizing

Normalizing involves heating the metal and then letting it cool in open air. This creates a more uniform and fine-grained crystal structure than annealing, resulting in a metal with higher strength and toughness. It is often used to refine the grain structure of parts that have been forged or cast.

Surface vs. Through Hardening

Treatments can affect the entire part uniformly or be concentrated on its surface.

Through Hardening

In this process, the entire cross-section of the component is heated and quenched to achieve a consistent hardness and microstructure from the surface to the core. This is suitable for parts that experience uniform stress.

Case Hardening (Carburizing, Nitriding)

Case hardening creates a part with two distinct zones: an extremely hard, wear-resistant outer layer (the "case") and a softer, tougher inner "core." This is achieved by diffusing elements like carbon (carburizing) or nitrogen (nitriding) into the surface at high temperatures. This dual-property structure is perfect for components like gears and bearings that must resist surface wear while also withstanding impact loads without fracturing.

Understanding the Trade-offs

Choosing a heat treatment is always an exercise in balancing competing properties.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness and strength, you almost always decrease its toughness and ductility. A very hard metal will resist scratching and wear, but it may shatter if dropped. A tougher metal will absorb impact energy by deforming, but it will wear out more quickly.

Distortion and Internal Stress

The rapid heating and cooling cycles inherent to many heat treatments can introduce significant internal stress. This stress can cause parts to warp, distort, or even crack if not properly managed.

Surface Finish and Contamination

Heating metal in the presence of oxygen can cause a rough, flaky layer of oxide ("scale") to form on the surface, which often must be cleaned off. Advanced methods like vacuum heat treatment prevent this by processing parts in a controlled environment, resulting in a clean, bright finish and reducing the risk of distortion.

Selecting the Right Treatment for Your Application

The optimal process is dictated entirely by the final goal for your component.

- If your primary focus is maximum wear resistance (e.g., cutting tools, dies): Your best choice is a hardening (quenching) process followed by tempering to balance hardness with minimal toughness.

- If your primary focus is maximum toughness and impact resistance (e.g., axles, structural bolts): A normalizing or a carefully controlled quench and temper process designed to favor toughness over peak hardness is the correct path.

- If your primary focus is maximum formability for manufacturing (e.g., sheet metal for stamping): Full annealing is the only process that will achieve the required softness and ductility.

- If your primary focus is a wear-resistant surface with a tough core (e.g., gears, camshafts): A case hardening process like carburizing or nitriding is the ideal solution.

By understanding these fundamental principles, you can deliberately engineer the performance of your metal components to meet any operational demand.

Summary Table:

| Process | Primary Goal | Key Outcome |

|---|---|---|

| Hardening (Quenching) | Maximum Hardness & Wear Resistance | Very hard but brittle structure |

| Tempering | Increase Toughness (after hardening) | Reduces brittleness, improves durability |

| Annealing | Maximum Softness & Ductility | Ideal for machining or forming |

| Normalizing | Uniform Strength & Toughness | Refines grain structure after forging/casting |

| Case Hardening | Hard Surface, Tough Core | Wear-resistant surface (e.g., gears, bearings) |

Ready to precisely engineer the properties of your metal components?

The right heat treatment process is critical for performance, but achieving consistent, high-quality results requires precise control. KINTEK's advanced lab furnaces and ovens are engineered to deliver the exact heating, soaking, and cooling profiles you need for processes like hardening, tempering, annealing, and case hardening.

We provide the reliable equipment and expert support to help you:

- Achieve Target Properties: Consistently meet specifications for hardness, toughness, and strength.

- Minimize Distortion: Our controlled environments help reduce warping and internal stress.

- Improve Surface Finish: Explore vacuum heat treatment options to prevent scale and contamination.

Don't leave your component's performance to chance. Contact our thermal processing experts today to discuss your application and find the perfect heat treatment solution for your laboratory needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is a natural sintering? Uncover the Geological Process That Forms Ore Deposits

- What are the specific hazards of the action of nanoparticles? Uncover the Risks of Nanoscale Materials

- What is the process of melting alloys? From Solidus to Liquidus for Precise Results

- What is pull down time in ULT freezers and what factors affect it? Ensure Your Sample Security with Efficient Cooling

- What are the advantages of selective heat sintering? Achieve Complex, Support-Free 3D Printed Parts

- What factors should be considered when choosing a ULT freezer for a lab? Ensure Maximum Sample Security and Efficiency

- What controls melting point? The Hierarchy of Forces from Ionic Bonds to Intermolecular Attractions

- How does DNA storage at -20°C and -80°C compare? Ensure Long-Term Sample Integrity