The short answer is that electromagnetic induction works perfectly in a vacuum because magnetic fields do not require any medium, such as air, to propagate. An alternating current in a coil will create a changing magnetic field that travels through the vacuum, inducing electrical currents in a conductive material and causing it to heat up, just as it would in air.

The critical insight is not that induction can work in a vacuum, but why it is used there. The vacuum’s role is not to enable the induction process, but to create an ultra-clean environment that prevents reactive liquid metals from being contaminated by oxygen and other atmospheric gases.

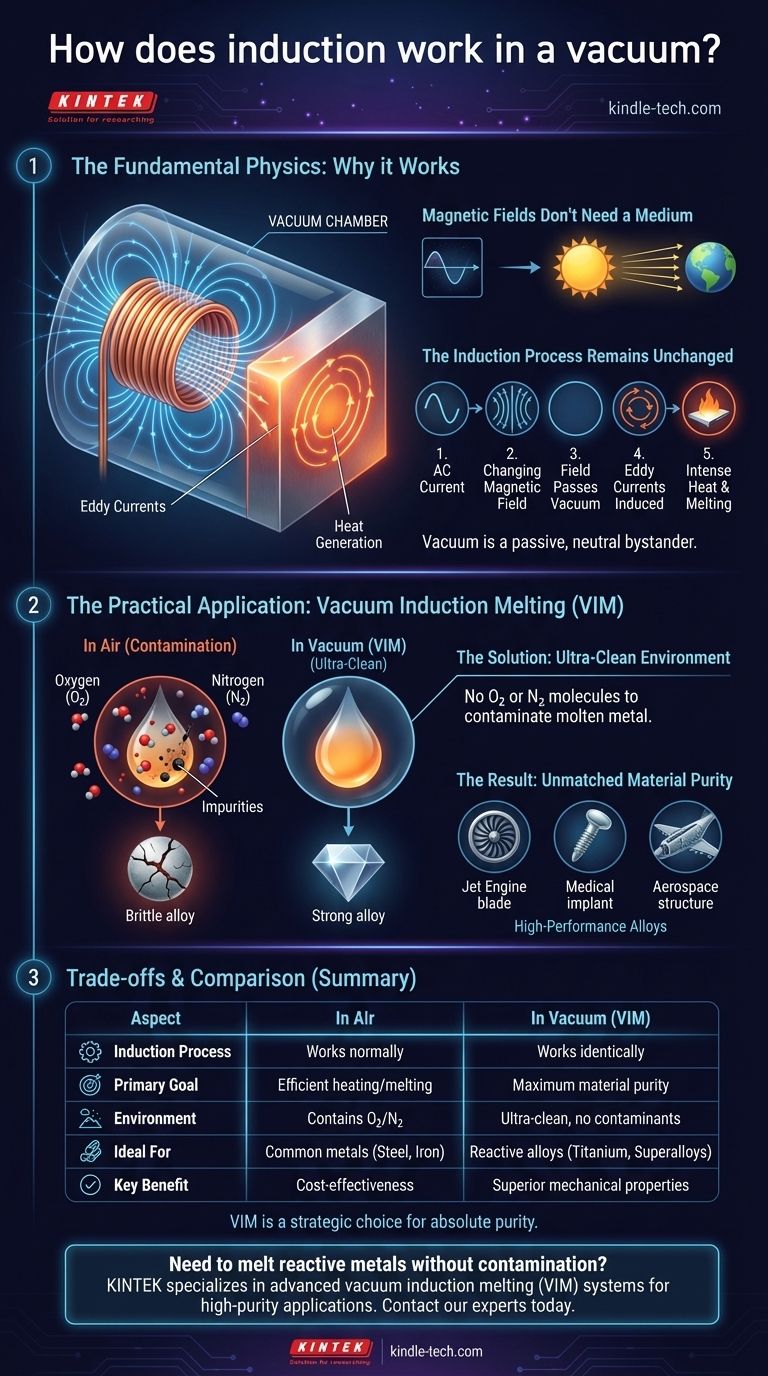

The Fundamental Physics: Why Induction Thrives in a Vacuum

The principles of electromagnetic induction are independent of the surrounding atmosphere. This is because the process relies on fundamental forces that operate just as effectively in empty space as they do in air.

Magnetic Fields Don't Need a Medium

Unlike sound, which requires molecules to travel, magnetic fields are a fundamental property of spacetime. They can propagate through the void of space without any loss of effect.

This is the same principle that allows light and heat from the sun to travel millions of miles through the vacuum of space to reach Earth.

The Induction Process Remains Unchanged

The sequence of events for induction heating is identical whether in air or in a vacuum.

- An alternating current (AC) is passed through an induction coil.

- This current generates a constantly changing magnetic field around the coil.

- The magnetic field passes unimpeded through the vacuum and penetrates any electrically conductive material placed inside the coil.

- This field induces swirling electrical currents, known as eddy currents, within the material.

- The material's natural electrical resistance fights against these eddy currents, generating intense heat and eventually causing the material to melt.

In this energy transfer, the vacuum is a passive, neutral bystander.

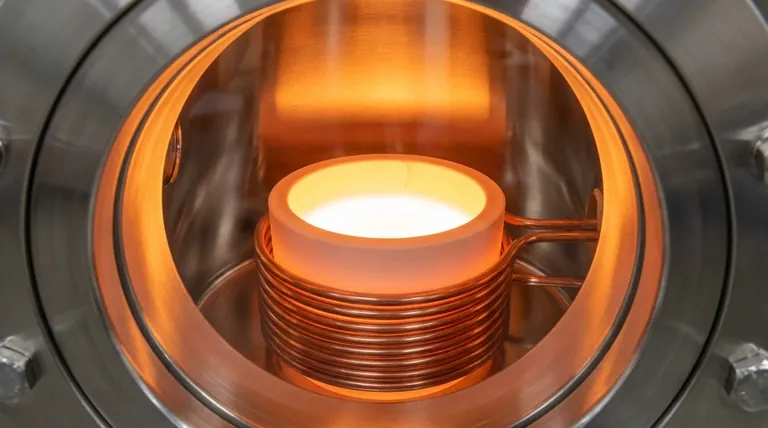

The Practical Application: Vacuum Induction Melting (VIM)

The primary reason to perform induction heating in a vacuum is for metallurgical purity. The process, known as Vacuum Induction Melting (VIM), is essential for producing the high-performance alloys required in demanding industries.

The Problem: Atmospheric Contamination

Many advanced metals and alloys, such as titanium or nickel-based superalloys, are highly reactive, especially when molten.

When melted in open air, they readily bond with oxygen and nitrogen. This creates impurities (oxides and nitrides) that severely degrade the material's strength, durability, and performance.

The Solution: An Ultra-Clean Environment

A VIM furnace is an airtight chamber from which nearly all air and other gases have been pumped out.

By performing induction melting inside this vacuum, there are no oxygen or nitrogen molecules available to contaminate the molten metal. This allows for precise control over the alloy's chemistry.

The Result: Unmatched Material Purity

The VIM process yields exceptionally clean, high-purity metals and alloys with superior mechanical properties. These materials are critical for components that must withstand extreme stress and temperature, such as jet engine turbine blades, medical implants, and aerospace structures.

Understanding the Trade-offs and Challenges

While powerful, using induction in a vacuum is a specialized and complex process with significant trade-offs compared to melting in a standard atmosphere.

Equipment Complexity and Cost

Vacuum induction furnaces are far more complex and expensive than their atmospheric counterparts. They require robust, water-cooled, airtight chambers, powerful vacuum pumping systems, and sophisticated controls to maintain the vacuum while managing the intense heat.

Material Selection is Critical

The crucible—the container holding the molten metal—must be made of a specialized refractory ceramic. This material must be able to withstand extreme temperatures without reacting with the alloy, and it must be non-conductive so the induction field heats the metal charge instead of the container.

Managing Outgassing

Even high-quality raw materials can contain trapped gases. As the metal melts under vacuum, these dissolved gases are released in a process called outgassing. This is beneficial for refining but must be actively managed by the vacuum system to maintain the desired pressure and purity.

When is Induction in a Vacuum Necessary?

Choosing to use a vacuum is a decision driven entirely by the required quality and type of the final material.

- If your primary focus is maximum purity and performance: For reactive metals like titanium or complex superalloys for aerospace or medical use, VIM is non-negotiable to prevent catastrophic contamination.

- If your primary focus is cost-effective melting of common metals: For standard metals like steel, iron, or aluminum where minor oxidation is acceptable or can be managed with other methods, a standard atmospheric induction furnace is the more practical and economical choice.

Ultimately, using induction in a vacuum is a strategic choice where the goal of absolute material purity justifies the significant investment in equipment and process complexity.

Summary Table:

| Aspect | In Air | In Vacuum (VIM) |

|---|---|---|

| Induction Process | Works normally | Works identically |

| Primary Goal | Efficient heating/melting | Maximum material purity |

| Environment | Contains oxygen/nitrogen | Ultra-clean, no contaminants |

| Ideal For | Common metals (steel, iron) | Reactive alloys (titanium, superalloys) |

| Key Benefit | Cost-effectiveness | Superior mechanical properties |

Need to melt reactive metals without contamination? KINTEK specializes in advanced vacuum induction melting (VIM) systems for laboratories and R&D facilities. Our furnaces provide the ultra-clean environment required for producing high-purity alloys for aerospace, medical, and high-performance applications. Contact our experts today to discuss how our VIM solutions can enhance your material research and production purity.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the main frequency of an induction furnace? A Guide to Optimizing Melting & Heating

- What is the role of an industrial vacuum induction furnace in melting 12% Cr martensitic steel? Pure & Tough Alloys

- What role do VIM and VAR equipment play in Inconel 718 preparation? Elevate Purity for Aerospace Superalloys

- How does an induction heating furnace work? Discover the Power of Internal, Contactless Heating

- What is the effect of frequency to induction hardening? Control Case Depth with Precision

- What is the process of induction furnace? Unlock Fast, Clean Metal Melting

- What are the process advantages of using vacuum induction melting equipment when preparing Fe-Cr-Zr ferritic alloys?

- What is the purpose of vacuum arc remelting? Achieve Unmatched Metal Purity and Performance