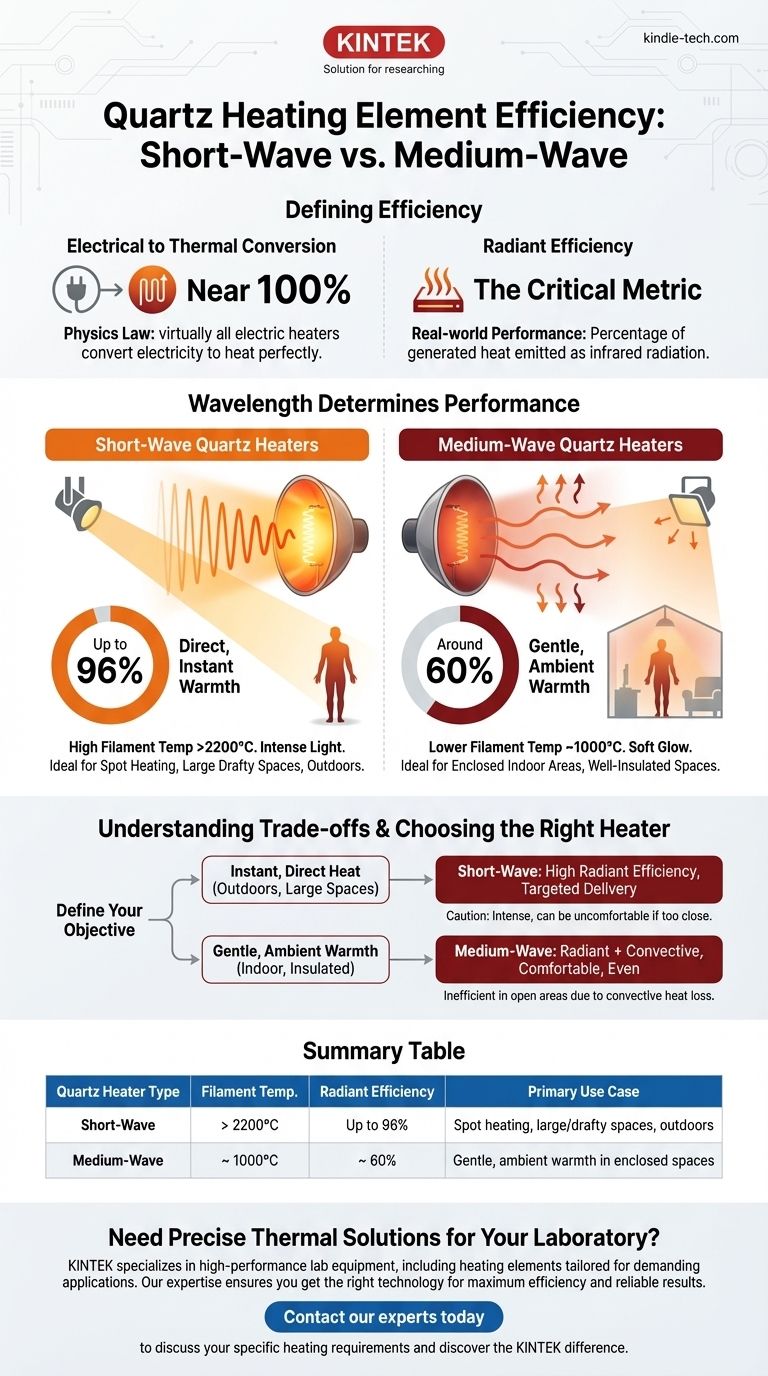

At its peak, a quartz heating element can be exceptionally efficient, but its effectiveness depends entirely on the type of infrared wavelength it produces. The radiant efficiency of a short-wave quartz heater can be as high as 96%, while a medium-wave heater operates at a lower radiant efficiency of around 60%.

The critical distinction is not how well a heater converts electricity to heat—virtually all are 100% efficient at that—but how effectively it delivers that heat to a target. This is measured by radiant efficiency, the key metric for understanding quartz heater performance.

The Two Types of "Efficiency" in Heating

When we discuss the efficiency of electric heaters, it's crucial to differentiate between two concepts. One is a law of physics, while the other determines real-world performance.

Electrical to Thermal Conversion (Near 100%)

Fundamentally, all electric resistance heaters, including quartz heaters, are nearly 100% efficient at converting electrical energy into heat. This is a basic principle of thermodynamics.

For every watt of electricity consumed, a corresponding watt of heat energy is produced. This fact, however, can be misleading if considered in isolation.

Radiant Efficiency (The Critical Metric)

The more important figure is radiant efficiency. This measures what percentage of the heat generated is emitted as infrared radiation.

Infrared radiation travels through the air and directly warms people and objects in its path without needing to heat the air in between. A higher radiant efficiency means more targeted, effective heating and less wasted energy.

Why Wavelength Determines Performance

The primary difference between quartz heaters lies in the wavelength of infrared energy they emit. This is dictated by the temperature of the heating element.

Short-Wave Quartz Heaters (Up to 96% Efficient)

Short-wave quartz heaters operate at very high filament temperatures (over 2200°C), producing an intense, bright light along with heat.

This high temperature results in a radiant efficiency of up to 96%. The vast majority of the energy is converted into powerful, short-wave infrared radiation.

Think of it like a spotlight. It projects focused energy directly onto a target, providing immediate warmth even from a distance. This makes it ideal for spot heating in large, drafty spaces or outdoor environments.

Medium-Wave Quartz Heaters (Around 60% Efficient)

Medium-wave heaters operate at lower temperatures (around 1000°C) and typically emit a soft, reddish glow.

At this temperature, the radiant efficiency is around 60%. The remaining 40% of the energy heats the surrounding air through convection.

This is more like a floodlight. The heat is less intense and spreads more diffusely, creating a gentler, ambient warmth. It is better suited for enclosed indoor areas where heating the air is also part of the goal.

Understanding the Trade-offs

Choosing a quartz heater isn't just about picking the highest efficiency number. The application dictates the best choice.

The Cost of High Intensity

The intense, directional heat from a short-wave heater can be uncomfortable if you are positioned too close. Its bright, visible light may also be undesirable in certain environments, such as a cozy living space.

The Inefficiency of Heating Air

Using a medium-wave heater in an open or poorly insulated area is inefficient. Much of the convective heat it produces will simply rise and dissipate, wasting energy without warming the occupants. This is why short-wave is the definitive choice for outdoor patios.

Making the Right Choice for Your Goal

To select the correct technology, you must first define your heating objective.

- If your primary focus is instant, direct heating for people or objects (especially outdoors or in large spaces): A short-wave quartz heater is the most efficient choice, as its high radiant efficiency delivers heat precisely where it's needed.

- If your primary focus is gentle, ambient warmth for a smaller, well-insulated indoor space: A medium-wave heater is a better fit, as its combination of radiant and convective heat provides more comfortable, even warmth.

Ultimately, understanding radiant efficiency empowers you to choose a heater that performs its job effectively without wasting energy.

Summary Table:

| Quartz Heater Type | Filament Temperature | Radiant Efficiency | Primary Use Case |

|---|---|---|---|

| Short-Wave | > 2200°C | Up to 96% | Spot heating, large/drafty spaces, outdoors |

| Medium-Wave | ~ 1000°C | ~ 60% | Gentle, ambient warmth in enclosed spaces |

Need precise thermal solutions for your laboratory?

KINTEK specializes in high-performance lab equipment, including heating elements tailored for demanding applications. Our expertise ensures you get the right technology for maximum efficiency and reliable results.

Contact our experts today to discuss your specific heating requirements and discover the KINTEK difference.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Multi-zone Laboratory Tube Furnace

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Automatic Laboratory Heat Press Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments