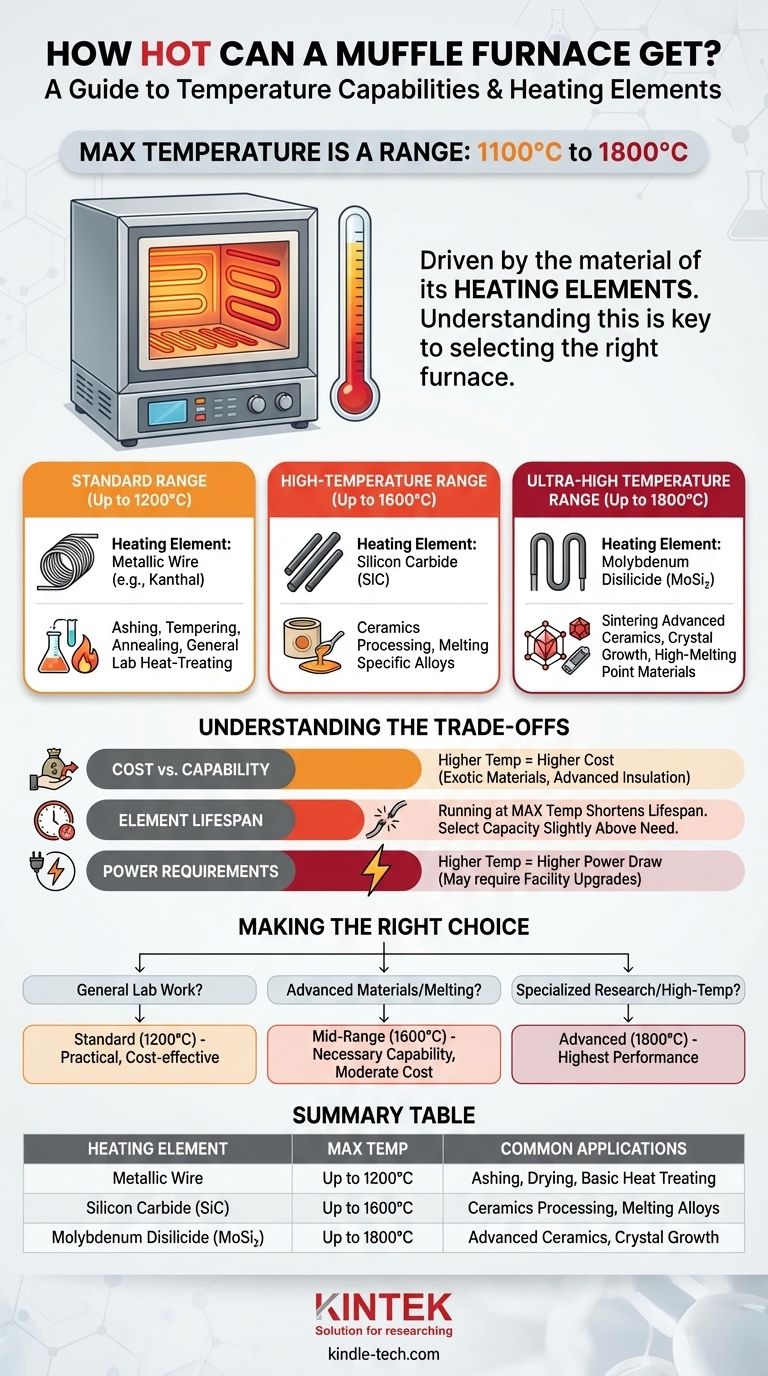

The maximum temperature of a muffle furnace is not a single value but a range determined by its specific design and components. While the most common laboratory models typically reach a maximum of 1100°C to 1200°C (2192°F), highly specialized furnaces built with advanced materials can achieve temperatures as high as 1800°C (3272°F).

The furnace's maximum temperature is dictated almost entirely by the material used for its internal heating elements. Understanding this relationship is the key to selecting a furnace that can safely and consistently meet the demands of your specific high-temperature application.

Why There Isn't One "Max Temp"

A "muffle furnace" is a category of equipment, not a single standardized product. Manufacturers design these furnaces for different purposes, from general-purpose lab work to specialized industrial processes, and the temperature capability is the primary differentiating factor.

The Critical Role of Heating Elements

The heart of an electric muffle furnace is its heating elements. These are the components that convert electrical energy into heat. The physical and chemical properties of the material used for these elements set a hard limit on the furnace's safe operating temperature.

Pushing an element beyond its designed maximum temperature will cause it to rapidly degrade, oxidize, or even melt, leading to premature failure.

A Breakdown of Capabilities by Heating Element

Furnace capabilities are best understood by segmenting them according to the type of heating element they employ.

Standard Range (Up to 1200°C): Metallic Wire Elements

These are the most common and cost-effective heating elements, typically made of an iron-chromium-aluminum alloy (like Kanthal).

They are the workhorses for a vast range of applications, including ashing, tempering, annealing, and general laboratory heat-treating.

High-Temperature Range (Up to 1600°C): Silicon Carbide (SiC) Elements

For processes that require temperatures beyond the limits of metallic wires, silicon carbide elements are used.

These are more robust and can handle more demanding applications, such as processing certain ceramics or melting some metals and alloys.

Ultra-High Temperature Range (Up to 1800°C): Molybdenum Disilicide (MoSi₂) Elements

These are the highest-performance elements commonly available. They are reserved for specialized research and industrial processes.

Applications include sintering advanced ceramics, growing crystals, and working with materials that have extremely high melting points.

Understanding the Trade-offs

Choosing a furnace with a higher temperature rating involves more than just performance; it comes with significant practical and financial implications.

Cost vs. Capability

The relationship is direct: a higher maximum temperature requires more exotic and expensive element materials and more advanced insulation. This results in a significantly higher initial purchase price for the furnace.

Element Lifespan and Operating Conditions

Consistently running a furnace at its absolute maximum rated temperature will shorten the lifespan of its heating elements. For longevity, it is often recommended to select a furnace with a maximum temperature slightly above your required process temperature.

Power and Facility Requirements

Higher temperature furnaces draw significantly more electrical power. An 1800°C furnace will have much more demanding power and ventilation requirements than a standard 1200°C lab model, which may require facility upgrades.

Making the Right Choice for Your Goal

Select a furnace based on the specific requirements of your process, not just the highest number.

- If your primary focus is general lab work (e.g., ashing, drying, basic heat treating): A standard furnace with metallic wire elements reaching up to 1200°C is the most practical and cost-effective choice.

- If your primary focus is advanced materials processing or melting lower-temp alloys: A mid-range furnace with silicon carbide (SiC) elements up to 1600°C provides the necessary capability without excessive cost.

- If your primary focus is specialized research with high-temp ceramics or specific metals: You will require an advanced furnace with molybdenum disilicide (MoSi₂) elements capable of reaching 1800°C.

Ultimately, matching the furnace's heating element technology to your specific temperature requirements is the key to a successful and efficient process.

Summary Table:

| Heating Element Type | Max Temperature Range | Common Applications |

|---|---|---|

| Metallic Wire (e.g., Kanthal) | Up to 1200°C | Ashing, drying, basic heat treating |

| Silicon Carbide (SiC) | Up to 1600°C | Ceramics processing, melting alloys |

| Molybdenum Disilicide (MoSi₂) | Up to 1800°C | Advanced ceramics, crystal growth |

Need a muffle furnace that matches your temperature requirements? KINTEK specializes in lab equipment and consumables, providing furnaces with the right heating element technology for your specific process—from general lab work to advanced materials research. Contact us today to discuss your application and get expert guidance on the ideal furnace for your lab's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the precautions of muffle furnace in laboratory? Ensure Operator Safety and Equipment Longevity

- What role does a high-temperature sintering furnace play in the preparation of silica-doped calcium sulfate bioceramics?

- What is the process of sintered ceramic? A Step-by-Step Guide to Transforming Powder into High-Performance Parts

- What critical role does a calcination furnace play in metal-based core-shell PCM processing? Expert Insights

- How does a 400°C holding stage affect nickel-alumina sintering? Ensure Structural Integrity & High Density

- What are the advantages of using a precision furnace for SrFeO3 synthesis? Low-Temp Efficiency and Nanoscale Control

- What is a lab drying oven used for? Master Moisture Removal & Sterilization for Your Lab

- What equipment is used in sintering? From Basic Furnaces to Advanced SPS & HIP Systems