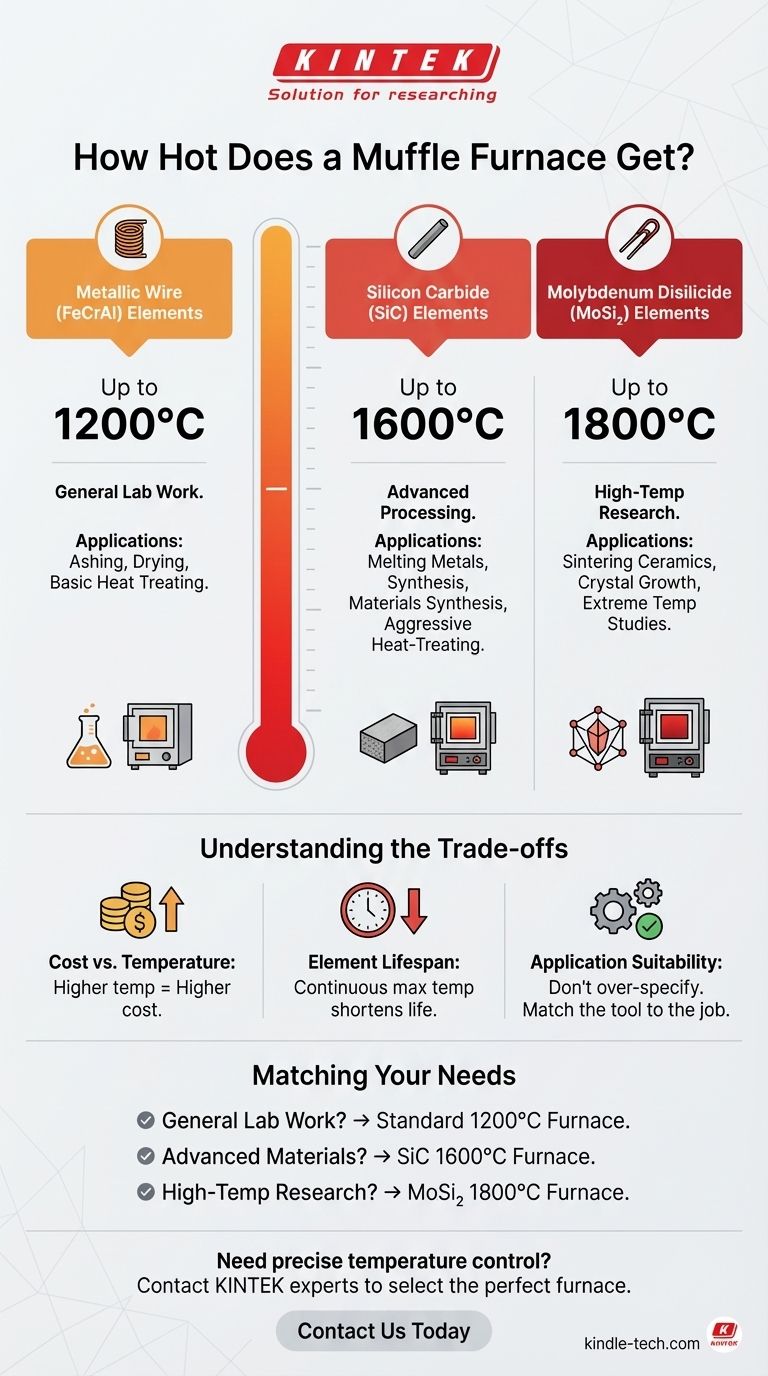

The maximum temperature of a muffle furnace is not a single value. While many common laboratory models operate in the 1000°C to 1200°C (2192°F) range, specialized industrial and research furnaces can reliably reach temperatures as high as 1800°C (3272°F). The specific maximum temperature is fundamentally determined by the materials used in its construction, particularly the heating elements.

The core takeaway is that a muffle furnace's temperature capability is directly tied to its heating element technology. Standard metallic elements handle general-purpose work up to 1200°C, while advanced ceramic elements are required for higher temperatures up to 1800°C.

Why Muffle Furnace Temperatures Vary So Widely

The term "muffle furnace" describes a wide category of equipment. The key differentiator that dictates performance and cost is the type of internal heating element used.

The Role of the Heating Element

The heating element is the component that converts electrical energy into heat. The material it's made from has an inherent temperature limit beyond which it will degrade or fail, defining the furnace's maximum operating temperature.

Common Metallic Wire Elements (Up to 1200°C)

The most common and cost-effective muffle furnaces use heating elements made from metallic alloys, such as iron-chromium-aluminum (FeCrAl).

These furnaces are the workhorses of many labs. They are perfectly suited for general-purpose applications like ashing, tempering, annealing, and drying.

Silicon Carbide (SiC) Elements (Up to 1600°C)

For applications requiring temperatures beyond the limits of metallic wires, furnaces employ silicon carbide heating elements.

These more robust elements open the door to processes like melting certain metals, advanced materials synthesis, and more aggressive heat-treating cycles.

Molybdenum Disilicide (MoSi₂) Elements (Up to 1800°C)

At the highest end of the spectrum are furnaces equipped with molybdenum disilicide heating elements.

These are designed for the most demanding scientific and industrial tasks. This includes sintering high-performance ceramics, growing crystals, and conducting research on materials at extreme temperatures.

Understanding the Trade-offs

Selecting a furnace isn't just about picking the highest number. The underlying technology involves critical trade-offs in cost, longevity, and application.

Cost vs. Temperature

There is a direct and steep correlation between maximum temperature and price. The advanced materials required for high-temperature elements and the necessary high-grade insulation significantly increase the furnace's cost.

Element Lifespan and Stability

Operating any furnace continuously at its absolute maximum temperature will shorten the lifespan of its heating elements. High-temperature elements like MoSi₂ can also be more brittle and require careful handling.

Application Suitability

Over-specifying a furnace is an unnecessary expense. A standard 1200°C unit is often more reliable and efficient for lower-temperature work than using a specialized 1800°C furnace for the same task.

Matching the Furnace to Your Application

Choosing the right furnace requires aligning its capabilities with your specific process needs.

- If your primary focus is general laboratory work (e.g., ashing, drying, basic heat treating): A standard furnace with metallic wire elements reaching 1100°C to 1200°C is sufficient and most cost-effective.

- If your primary focus is advanced materials processing or specific metal treatments: You will likely require a furnace with silicon carbide (SiC) elements capable of reaching up to 1600°C.

- If your primary focus is high-temperature research with specialized ceramics and alloys: A furnace with molybdenum disilicide (MoSi₂) elements, capable of 1800°C, is necessary for these demanding applications.

Ultimately, understanding the heating element technology is the key to selecting a muffle furnace that precisely meets your high-temperature requirements.

Summary Table:

| Heating Element Type | Typical Max Temperature | Ideal Applications |

|---|---|---|

| Metallic Wire (FeCrAl) | Up to 1200°C | Ashing, drying, basic heat treating |

| Silicon Carbide (SiC) | Up to 1600°C | Advanced materials processing, metal treatments |

| Molybdenum Disilicide (MoSi₂) | Up to 1800°C | High-temperature research, specialized ceramics |

Need precise temperature control for your laboratory processes? KINTEK specializes in lab equipment and consumables, offering muffle furnaces with the right heating element technology for your specific application—from general lab work to advanced materials research. Our experts will help you select the perfect furnace to enhance your lab's efficiency and accuracy. Contact us today to discuss your high-temperature requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- What is the use of muffle furnace in food lab? Essential for Accurate Ash Content Analysis

- What is the primary characteristic of a muffle furnace? Unlock Pure, Contamination-Free Heating

- What is the heat transfer of a muffle furnace? Understanding Indirect Heating for Purity

- What is the cooling rate for a muffle furnace? Achieve Optimal Cooling for Your Lab Processes