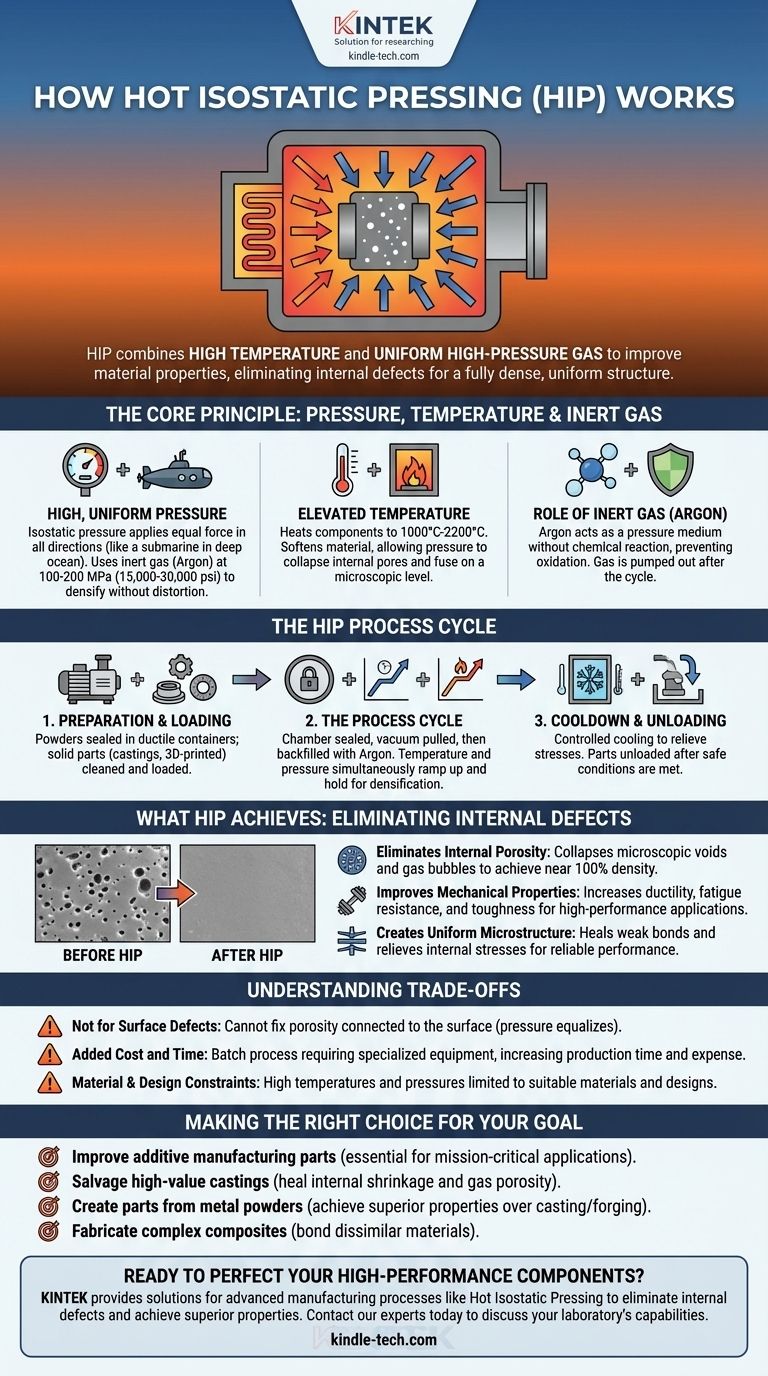

At its core, hot isostatic pressing (HIP) is a manufacturing process that uses a combination of high temperature and uniform, high-pressure gas to improve the properties of metals, ceramics, and other materials. It functions like a high-pressure oven, simultaneously heating a component and squeezing it from all directions to eliminate internal defects and create a fully dense, uniform structure.

The fundamental purpose of HIP is to remove internal porosity. By subjecting a part to temperatures near its sintering point and applying extreme, uniform pressure with an inert gas, the process collapses internal voids, fuses metallurgical bonds, and creates a material with superior mechanical properties.

The Core Principle: Temperature, Pressure, and Inert Gas

The effectiveness of HIP lies in the precise control of three key elements working in unison within a sealed, high-pressure chamber.

High, Uniform Pressure

Hot isostatic pressing applies isostatic pressure, meaning it is equal in all directions. Imagine a submarine deep in the ocean—the water pressure is the same on every single point of its hull.

HIP achieves this using an inert gas, typically argon, pressurized to between 100 and 200 MPa (15,000 to 30,000 psi). This uniform pressure ensures that a part is densified without distorting its net shape.

Elevated Temperature

Inside the pressure vessel, a high-temperature furnace heats the components. The target temperature, ranging from 1000°C to 2200°C, is chosen based on the material being processed.

This heat softens the material, making it malleable enough for the high pressure to collapse internal pores and weld the material together on a microscopic level.

The Role of Inert Gas

An inert gas like argon is critical because it acts as the pressure-transfer medium without chemically reacting with the part.

Using a reactive gas like oxygen would cause oxidation and ruin the material at these high temperatures. Argon simply applies the pressure, does its job, and is pumped out afterward, leaving the material's chemistry unchanged.

The Step-by-Step HIP Process

While the specific parameters are tailored to each application, the operational sequence follows a consistent and highly controlled path.

1. Preparation and Loading

For parts made from metal powders, the powder is first sealed under vacuum in a metal or glass container that will become ductile at the HIP temperature.

For existing solid parts, such as castings or 3D-printed components, they are simply cleaned and loaded directly into the HIP unit's chamber.

2. The Process Cycle

Once the chamber is sealed, a computer-controlled program begins. The system first pulls a vacuum to remove any reactive gases.

Next, it backfills the chamber with argon and begins to simultaneously ramp up the temperature and pressure. The components are held at the target temperature and pressure for a specific duration, allowing the material to densify fully.

3. Cooldown and Unloading

After the cycle is complete, the components are cooled in a controlled manner to relieve thermal stresses. Once back at a safe temperature and pressure, the parts are unloaded.

The entire process, from loading to unloading, can take several hours, depending on the material and the size of the load.

What HIP Achieves: Eliminating Internal Defects

The primary goal of HIP is to resolve microscopic imperfections that compromise a part's performance and structural integrity.

Eliminating Internal Porosity

Whether it's tiny gas bubbles in a casting or microscopic voids between layers in a 3D-printed part, HIP forces these empty spaces to collapse and disappear. This raises the part's density to nearly 100% of its theoretical maximum.

Improving Mechanical Properties

By removing defects, HIP dramatically improves a material's performance. The result is increased ductility, fatigue resistance, and overall toughness. This is critical for high-performance parts used in aerospace, medical, and energy applications.

Creating a Uniform Microstructure

The process heals weak bonds between layers in additively manufactured parts and relieves internal stresses in castings. This creates a homogenous, consistent material structure, ensuring reliable and predictable performance under load.

Understanding the Trade-offs

While incredibly powerful, HIP is not a universal solution. Understanding its limitations is key to using it effectively.

Not a Fix for Surface Defects

The HIP process relies on external pressure to close internal voids. It cannot fix porosity or cracks that are connected to the part's surface, as the pressure inside the defect will equalize with the chamber pressure.

Added Cost and Time

HIP is a batch process that requires specialized, expensive equipment. It adds a significant step to the manufacturing workflow, increasing both the cost per part and the overall lead time.

Material and Design Constraints

The process is best suited for high-value components where performance and reliability are non-negotiable. The high temperatures and pressures can also place constraints on the design and material selection for the parts being treated.

Making the Right Choice for Your Goal

Deciding whether to use HIP depends entirely on your material, manufacturing method, and performance requirements.

- If your primary focus is improving additively manufactured parts: HIP is essential for closing internal porosity and creating a homogenous microstructure required for mission-critical applications.

- If your primary focus is salvaging high-value castings: HIP can heal internal shrinkage and gas porosity, dramatically increasing the yield and reliability of cast components.

- If your primary focus is creating parts from metal powders: HIP is a powerful method for achieving full densification and creating materials with properties superior to those made by casting or forging.

- If your primary focus is fabricating complex composites: HIP provides the necessary heat and pressure to bond dissimilar materials together, such as in the creation of metal matrix composites.

Ultimately, hot isostatic pressing is a finishing tool that transforms good components into exceptional ones by perfecting their internal structure.

Summary Table:

| Key Element | Function | Typical Range |

|---|---|---|

| Pressure | Applies uniform, isostatic force from all directions | 100 - 200 MPa (15,000 - 30,000 psi) |

| Temperature | Softens material to allow densification | 1000°C - 2200°C |

| Gas Medium | Inert gas (Argon) transfers pressure without chemical reaction | Argon |

| Primary Benefit | Eliminates internal porosity, increases fatigue life and toughness | Achieves near 100% density |

Ready to perfect your high-performance components?

KINTEK specializes in lab equipment and consumables, providing solutions for advanced manufacturing processes like Hot Isostatic Pressing. Our expertise can help you eliminate internal defects in your castings, 3D-printed parts, and powder metallurgy components, resulting in superior mechanical properties and reliability.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and material performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the function of a vacuum hot pressing furnace (VHP)? Master Ti/Ti-Al Composite Fabrication

- What are the benefits of utilizing a Vacuum Hot Press (VHP) for Mg3Sb2? Maximize Thermoelectric Efficiency Today

- What are the effects of sintering pressure? Achieve Higher Density and Control Microstructure

- Why is precise pressure control from a vacuum hot press furnace necessary for IZO ceramic targets? Ensure High Density

- How does the vacuum system of a laboratory hot press sintering furnace influence CuW30 properties? Maximize Purity.

- Why is Spark Plasma Sintering (SPS) preferred over Hot Press (HP) for LLZT? Achieve Faster, High-Density Synthesis

- What is the process of plasma sintering? Achieve Rapid, High-Performance Material Densification

- Why is a hot-press setup used instead of traditional high-temperature sintering? Optimize LATP/NCM-811 Interface Study