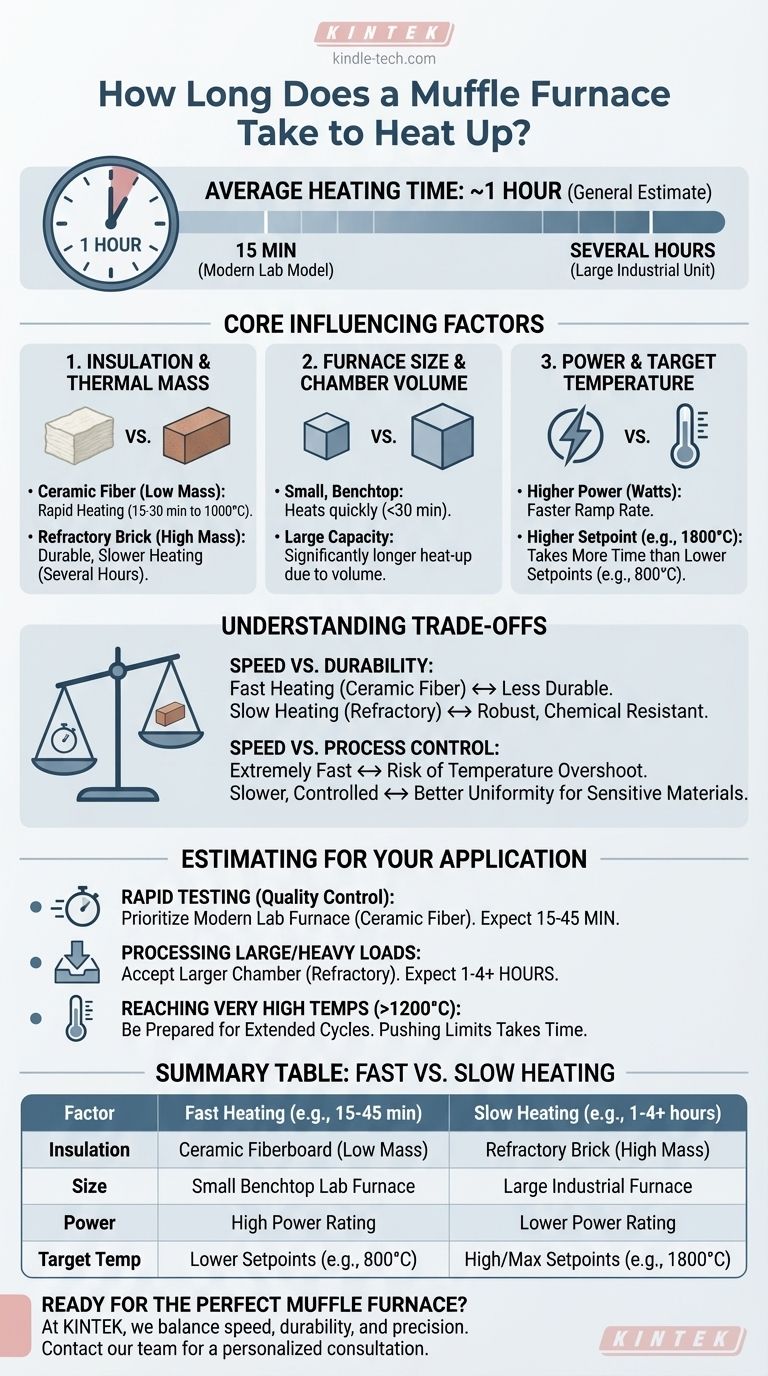

On average, a muffle furnace takes about an hour to reach its target temperature. However, this is only a general estimate. The actual time can vary dramatically, ranging from as little as 15 minutes for a modern laboratory model to several hours for a large industrial unit.

The heating time of a muffle furnace is not a single, fixed value. It is a direct result of three key factors: the furnace's physical design (size and insulation), its electrical power, and the specific temperature you need to achieve.

The Core Factors Influencing Heat-Up Time

To accurately estimate the time required for your specific application, you must consider the fundamental characteristics of the furnace itself.

Insulation Material and Thermal Mass

This is the single most important factor. The materials used to insulate the heating chamber dictate how quickly it can reach temperature.

Modern furnaces often use ceramic fiberboard, which has low thermal mass. This allows for very rapid heating, sometimes reaching 1000°C in just 15 to 30 minutes.

Older or more specialized furnaces may use dense refractory brick. While highly durable, this material absorbs a significant amount of heat, meaning it can take several hours to reach the target temperature.

Furnace Size and Chamber Volume

The physics are straightforward: a larger chamber contains more air and has a greater surface area to heat.

A small, benchtop laboratory furnace can heat quickly, often in under 30 minutes. A large-capacity industrial furnace will invariably have a much longer heat-up cycle due to its sheer volume.

Maximum Power Rating

The furnace's power, measured in watts or kilowatts, determines the rate at which it can generate heat.

A higher power rating allows for a faster temperature ramp rate. An underpowered furnace, especially a large one, will struggle to overcome heat loss and will take significantly longer to reach its setpoint.

The Target Temperature (Setpoint)

The temperature you need to achieve directly impacts the time it takes to get there.

Reaching a common heat-treating temperature of 800°C will be much faster than pushing the furnace to its upper limits for sintering or melting, which can be as high as 1800°C.

Understanding the Trade-offs

Choosing a furnace isn't just about finding the fastest one. The design choices that influence heating speed involve critical performance trade-offs.

Speed vs. Durability

Lightweight ceramic fiber insulation enables rapid heating but can be more susceptible to mechanical damage or chemical degradation over time.

Dense refractory materials heat slowly but are exceptionally robust, making them suitable for harsh industrial environments and processes with corrosive byproducts.

Speed vs. Process Control

Extremely fast heating rates can sometimes lead to temperature "overshoot," where the chamber temporarily exceeds the setpoint.

For sensitive materials or processes that require precise temperature uniformity, a slower, more controlled ramp-up is often preferable to ensure the entire workload is heated evenly.

How to Estimate for Your Application

Instead of looking for a single number, evaluate your primary goal to determine what to expect.

- If your primary focus is rapid testing or quality control: Prioritize a modern lab furnace with ceramic fiber insulation, which should reach its setpoint in 15-45 minutes.

- If your primary focus is processing large or heavy loads: Accept that a larger chamber with durable refractory materials will have a much slower heat-up time, likely one to several hours.

- If your primary focus is reaching very high temperatures (above 1200°C): Be prepared for an extended heating cycle, as pushing a furnace to its maximum operational limit always takes the most time.

Understanding these core principles allows you to move beyond asking "how long" and start determining the right heating profile for your specific objective.

Summary Table:

| Factor | Fast Heating (e.g., 15-45 min) | Slow Heating (e.g., 1-4+ hours) |

|---|---|---|

| Insulation | Ceramic Fiberboard (Low Mass) | Refractory Brick (High Mass) |

| Size | Small Benchtop Lab Furnace | Large Industrial Furnace |

| Power | High Power Rating | Lower Power Rating |

| Target Temperature | Lower Setpoints (e.g., 800°C) | High/ Max Setpoints (e.g., 1800°C) |

Ready to find the perfect muffle furnace for your lab's specific heating needs?

At KINTEK, we specialize in providing laboratory equipment solutions that balance speed, durability, and precise temperature control. Whether you need a rapid-heating ceramic fiber furnace for quick quality control tests or a robust refractory-lined model for heavy-duty industrial processing, our experts can help you select the right equipment to optimize your workflow and efficiency.

Contact our team today for a personalized consultation and let KINTEK power your laboratory's success.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a muffle furnace and a blast furnace? Precision vs. Production

- What is the difference between an oven and a muffle furnace? A Guide to Selecting the Right Thermal Equipment

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- What is the working principle of muffle furnace? Achieving Pure, Uniform High-Temperature Processing

- What is the difference between muffle furnace and hot oven? A Guide to Choosing the Right Thermal Tool