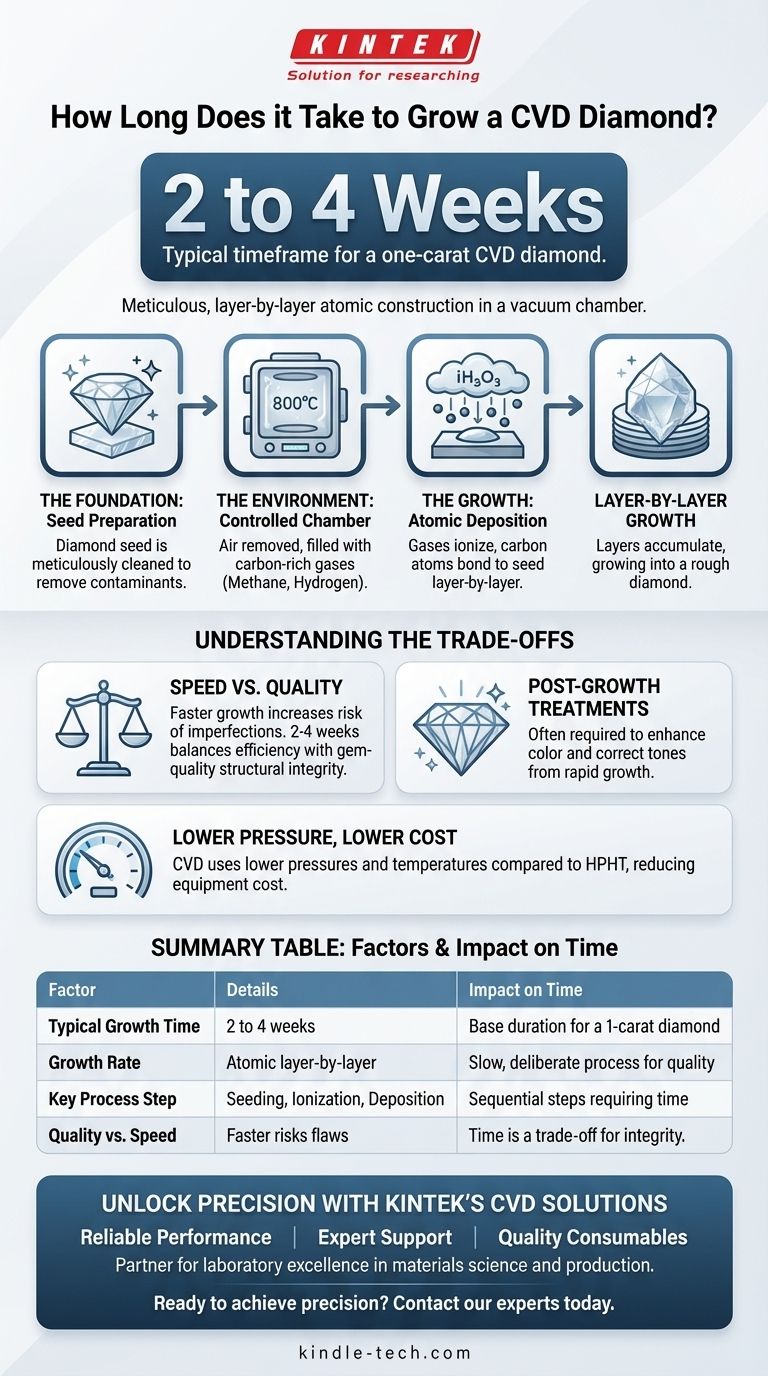

In short, growing a one-carat CVD diamond typically takes between two and four weeks. This timeframe allows for the meticulous, layer-by-layer atomic construction required to form a high-quality gemstone inside a specialized vacuum chamber.

The time required to grow a CVD diamond is a direct reflection of its controlled, atom-by-atom growth process. While significantly faster than nature, this two-to-four-week period represents the deliberate pace needed to ensure structural integrity and quality in the final crystal.

The CVD Growth Process: An Atomic Blueprint

To understand why it takes several weeks to grow a CVD diamond, you must first understand the method. It is less like baking and more like 3D printing on an atomic scale.

The Foundation: Preparing the Seed

The process begins with a diamond seed. This is a very thin, flat slice of a previously created diamond.

This seed is meticulously cleaned to remove any microscopic dust or contaminants, as any impurity can disrupt the crystal growth and create flaws.

The Environment: A Controlled Chamber

The seed is placed inside a vacuum chamber. All air is removed to create a pure, controlled environment.

The chamber is then heated to an extremely high temperature, typically around 800°C, and filled with a precise mixture of carbon-rich gases, such as methane and hydrogen.

The Growth: Atomic Deposition

The intense heat and pressure cause the gases to ionize, breaking the molecules apart and releasing pure carbon atoms.

These carbon atoms "rain down" onto the cooler diamond seed, bonding to its crystal lattice one by one. Over weeks, these layers accumulate, growing the original seed into a larger, rough diamond.

Understanding the Trade-offs

The CVD method's timeframe and process come with distinct advantages and necessary compromises. It is not simply a matter of speed.

Post-Growth Treatments are Common

While the process is highly controlled, many CVD diamonds require post-growth treatment to enhance their color. This extra step is often needed to correct tones that can develop during the rapid growth cycle.

A Balance of Speed and Quality

Producers could theoretically speed up the process, but this would dramatically increase the risk of inclusions and imperfections in the crystal structure.

The two-to-four-week timeframe is the industry's equilibrium point, balancing an efficient production schedule with the need to create a high-quality, gem-worthy diamond.

Lower Pressure, Lower Cost

Compared to the alternative HPHT (High Pressure/High Temperature) method, CVD uses significantly lower pressures and temperatures. This reduces the upfront equipment cost and complexity, making the technology more accessible.

What This Means for You

Understanding the growth time provides critical context for evaluating CVD diamonds, whether for purchase or for technological appreciation.

- If your primary focus is on the technology: Recognize that CVD is a feat of additive manufacturing, where time is a function of atomic precision, not just a simple chemical reaction.

- If your primary focus is on purchasing a diamond: The growth time confirms its lab-created origin and influences its final cost, but be aware that post-growth treatments are a normal part of achieving top-tier color.

Ultimately, knowing the process behind the product empowers you to assess its quality and value with true clarity.

Summary Table:

| Factor | Details | Impact on Time |

|---|---|---|

| Typical Growth Time | 2 to 4 weeks | Base duration for a 1-carat diamond |

| Growth Rate | Atomic layer-by-layer deposition | Slow, deliberate process for quality |

| Key Process Step | Seeding, gas ionization, carbon deposition | Sequential steps that require time |

| Quality vs. Speed | Faster growth risks inclusions and flaws | Time is a trade-off for structural integrity |

Unlock Precision with KINTEK's CVD Solutions

Understanding the precise nature of CVD diamond growth is key to achieving superior results in your research or production. At KINTEK, we specialize in providing the high-quality lab equipment and consumables that power this advanced technology.

Why choose KINTEK for your CVD needs?

- Reliable Performance: Our equipment ensures the stable, controlled environments necessary for consistent, high-quality diamond growth.

- Expert Support: Leverage our deep expertise in laboratory processes to optimize your CVD operations.

- Quality Consumables: From diamond seeds to specialized gases, we supply the pure materials required for flawless crystal formation.

Whether you are advancing materials science or developing next-generation applications, KINTEK is your trusted partner in laboratory excellence.

Ready to achieve precision in your lab? Contact our experts today to discuss how our solutions can meet your specific CVD requirements.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

People Also Ask

- What are nanotubes drawbacks? The 4 Major Hurdles Limiting Their Real-World Use

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What are the challenges of carbon nanotubes? Overcoming Production and Integration Hurdles