The lifespan of a PVD coating is highly variable, ranging from a decade for high-wear consumer products to a virtual lifetime for decorative items that see little contact. The longevity is not a single number but a function of the coating's composition, its thickness, the underlying material, and most importantly, the daily wear and tear it endures.

The core question isn't just how long PVD lasts, but what causes it to wear. Unlike paint, PVD doesn't chip or peel; it gradually abrades over time. Therefore, its functional lifespan is directly tied to its environment and use.

The Science of PVD Durability

Physical Vapor Deposition (PVD) is not a layer of paint or a traditional plating process. It is a vacuum-based process where a solid material is vaporized and then deposited, atom by atom, onto the surface of a part.

This method creates a thin film that is molecularly bonded to the substrate material. This bond is the source of PVD's exceptional durability and resistance to wear.

The Substrate Material

The foundation of any good coating is the material it's applied to, known as the substrate.

PVD adheres best to hard, stable materials like stainless steel, titanium, and carbide. Softer materials like aluminum or plastics require specific undercoats to achieve similar longevity.

Coating Thickness and Composition

The thickness of a PVD coating is measured in microns (millionths of a meter). While a thicker coating can offer more wear resistance, the specific material used is often more important.

Coatings like Titanium Nitride (TiN) or Zirconium Nitride (ZrN) have different properties of hardness and color, which are selected based on the product's intended use.

The Application Environment

This is the single most critical factor in determining how long a PVD coating will last in the real world.

A PVD-coated faucet fixture that is only touched a few times a day may look new for decades. In contrast, a PVD-coated watch bracelet, which is constantly rubbing against desks and clothing, might show signs of wear after 5-10 years.

Understanding the Limitations and Failure Points

While exceptionally tough, PVD coatings are not indestructible. Understanding how they fail is key to evaluating their suitability for your application.

Failure Is Not Flaking, It's Fading

A properly applied PVD coating will not flake or peel off. Failure occurs through abrasion—the coating slowly wears thin over many years, eventually revealing the substrate underneath.

This typically happens first on sharp edges and corners, which experience the most contact and friction.

The Myth of Indestructibility

PVD coatings are extremely hard, but they are also very thin. A severe impact or deep scratch that damages the underlying substrate will also damage the coating on top of it.

The coating can resist scratches that would mar the base material, but it cannot protect the base material from deforming under heavy impact.

Making the Right Decision for Your Application

Choosing PVD should be based on a clear understanding of your product's requirements and its expected lifecycle.

- If your primary focus is extreme wear resistance (e.g., cutting tools, industrial components): PVD offers a significant increase in lifespan, but the specific coating composition (like TiCN or AlTiN) is the most important factor.

- If your primary focus is a durable decorative finish (e.g., jewelry, watches, architectural hardware): PVD is an excellent choice that will last for many years, with the understanding that high-contact areas will show wear first.

- If your primary focus is color fastness: PVD coatings are far superior to traditional plating in their resistance to UV light and discoloration, ensuring a stable color for the life of the coating.

Ultimately, the longevity of a PVD finish is a testament to its quality of application and its suitability for the environment it was designed for.

Summary Table:

| Factor | Impact on PVD Coating Lifespan |

|---|---|

| Application Environment | Most critical factor. Low-wear items last decades; high-wear items show wear in 5-10 years. |

| Coating Composition | Materials like TiN or ZrN offer different hardness levels for specific wear resistance needs. |

| Substrate Material | Adheres best to hard materials like stainless steel or titanium for maximum longevity. |

| Coating Thickness | Thicker coatings (in microns) generally offer increased resistance to abrasion over time. |

Need a durable, long-lasting finish for your products? The lifespan of your PVD coating depends on precise application and material science. At KINTEK, we specialize in advanced lab equipment and consumables for PVD processes, ensuring your coatings are optimized for maximum durability. Let our expertise help you select the right materials and parameters for your specific application—from industrial components to decorative finishes.

Contact our experts today to discuss how we can support your laboratory's PVD coating success and achieve superior, long-lasting results.

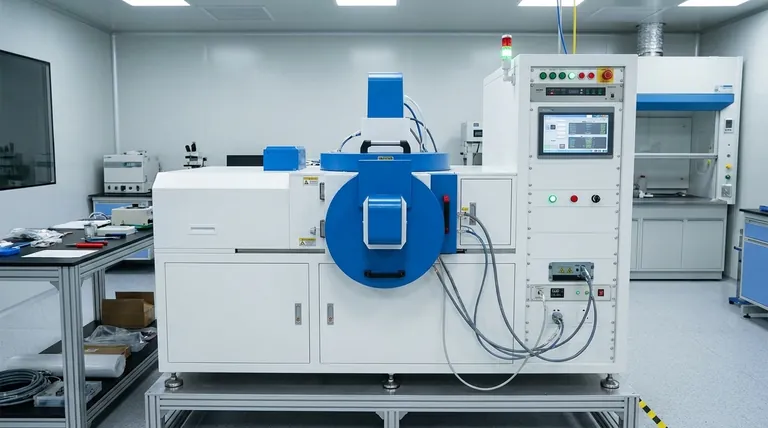

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications