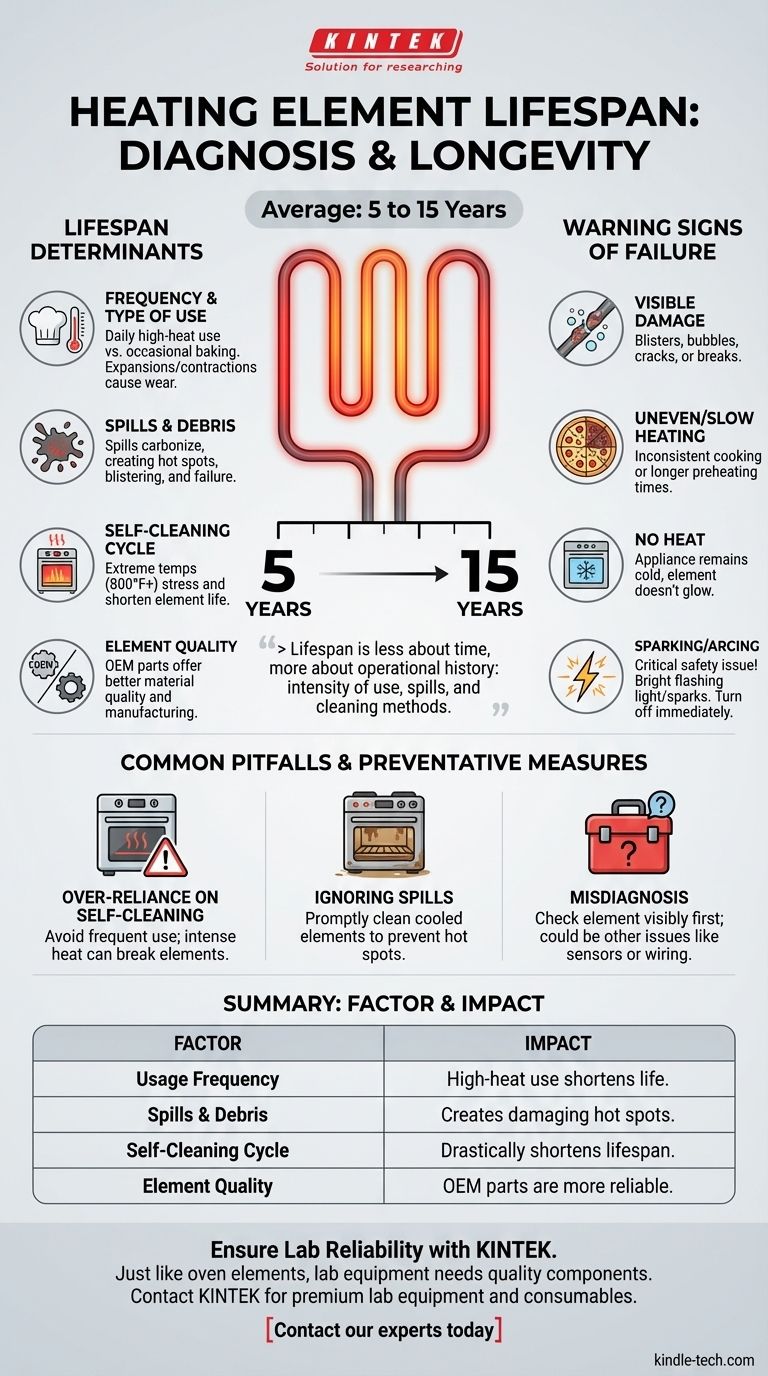

On average, an oven heating element is designed to last between 5 and 15 years. This wide range is not arbitrary; it is a direct result of factors like usage frequency, cleaning habits, and the initial quality of the component. Understanding these variables is the key to diagnosing a problem and extending the life of your appliance.

The lifespan of a heating element is less a matter of time and more a reflection of its operational history. The most significant factors are not years, but the intensity of use and the impact of physical damage from spills and high-heat cleaning cycles.

What Determines a HeatingElement's Lifespan?

The 5-to-15-year estimate is a general guideline. The actual service life of your element is determined by the specific conditions it endures.

Frequency and Type of Use

An oven used daily for high-temperature roasting will place significantly more stress on its heating element than one used a few times a week for baking at moderate temperatures. Each heating and cooling cycle causes the metal to expand and contract, which contributes to wear over time.

The Impact of Spills and Debris

Food and grease spilling directly onto a hot element is a primary cause of premature failure. The spill carbonizes, creating an insulating layer that traps heat in one spot. This "hot spot" can cause the element's metal sheath to blister, crack, or burn out.

The Self-Cleaning Cycle

The self-cleaning function is arguably the single most strenuous event for a heating element. This cycle operates at extremely high temperatures (over 800°F / 425°C), pushing the element to its absolute limit for an extended period, which can significantly shorten its lifespan.

Quality of the Element Itself

Original Equipment Manufacturer (OEM) parts are typically built to specific tolerances for a given appliance. While many aftermarket parts are reliable, variations in material quality and manufacturing can sometimes lead to a shorter operational life.

Recognizing the Signs of a Failing Element

Failure is rarely instantaneous. An element will almost always show signs of degradation before it stops working completely, giving you an opportunity to diagnose the issue.

Visible Damage

The most definitive evidence is physical damage. Look for any blisters, bubbles, cracks, or holes along the length of the element. A section that is visibly broken is a clear sign of failure.

Uneven Heating or Slow Preheating

If you notice that food is cooking unevenly or the oven is taking much longer than usual to reach the set temperature, the element may be losing its ability to heat consistently across its entire surface.

No Heat at All

This is the most obvious symptom. If the oven controls are on but the appliance remains cold, and the bake or broil element doesn't glow red, it has likely failed completely.

Sparking or Arcing

Seeing a bright, flashing light or sparks from the element during operation is a critical safety issue. This indicates a severe break in the element's sheath. You should immediately turn off the oven and disconnect it from power.

Common Pitfalls to Avoid

Understanding common mistakes can help you prevent premature failure and make informed decisions about maintenance and repair.

Over-Reliance on Self-Cleaning

Many homeowners experience heating element failure immediately following a self-clean cycle. The intense, prolonged heat is simply too much for an older or slightly damaged element to withstand.

Ignoring Spills

Letting spills sit and bake onto the element is a direct path to creating damaging hot spots. Cleaning them (once the oven is completely cool) is one of the most effective preventative measures.

Misdiagnosing the Problem

Sometimes, a lack of heat isn't the element's fault. It could be a faulty temperature sensor, a bad control board, or a wiring issue. A simple visual inspection of the element is the best first step to rule out the most common cause.

Making the Right Choice for Your Goal

By understanding these factors, you can tailor your usage and maintenance habits to match your priorities.

- If your primary focus is maximizing lifespan: Manually clean your oven, promptly address any spills, and use the self-cleaning feature sparingly, if at all.

- If your primary focus is convenience: Understand that frequent use of the self-clean cycle will likely shorten the element's life, and budget for a potential replacement sooner.

- If you suspect a problem: Perform a careful visual inspection for breaks or blisters before assuming a more complex electrical issue is at play.

Ultimately, knowing what influences your heating element's health puts you in control of your appliance's performance and longevity.

Summary Table:

| Factor | Impact on Lifespan |

|---|---|

| Usage Frequency | Daily, high-heat use shortens life significantly. |

| Spills & Debris | Creates hot spots, leading to blistering and failure. |

| Self-Cleaning Cycle | Extremely high temperatures can drastically shorten lifespan. |

| Element Quality | OEM parts are typically more durable and reliable. |

Is your lab equipment's performance inconsistent? Just like a reliable oven heating element, your lab instruments require durable, high-quality components for precise and consistent results. KINTEK specializes in premium lab equipment and consumables, ensuring your laboratory operates at peak efficiency and reliability. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Infrared Heating Quantitative Flat Plate Press Mold

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- What function do molybdenum disilicide heating elements perform? Precision Heat for Pulverized Coal Research

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance