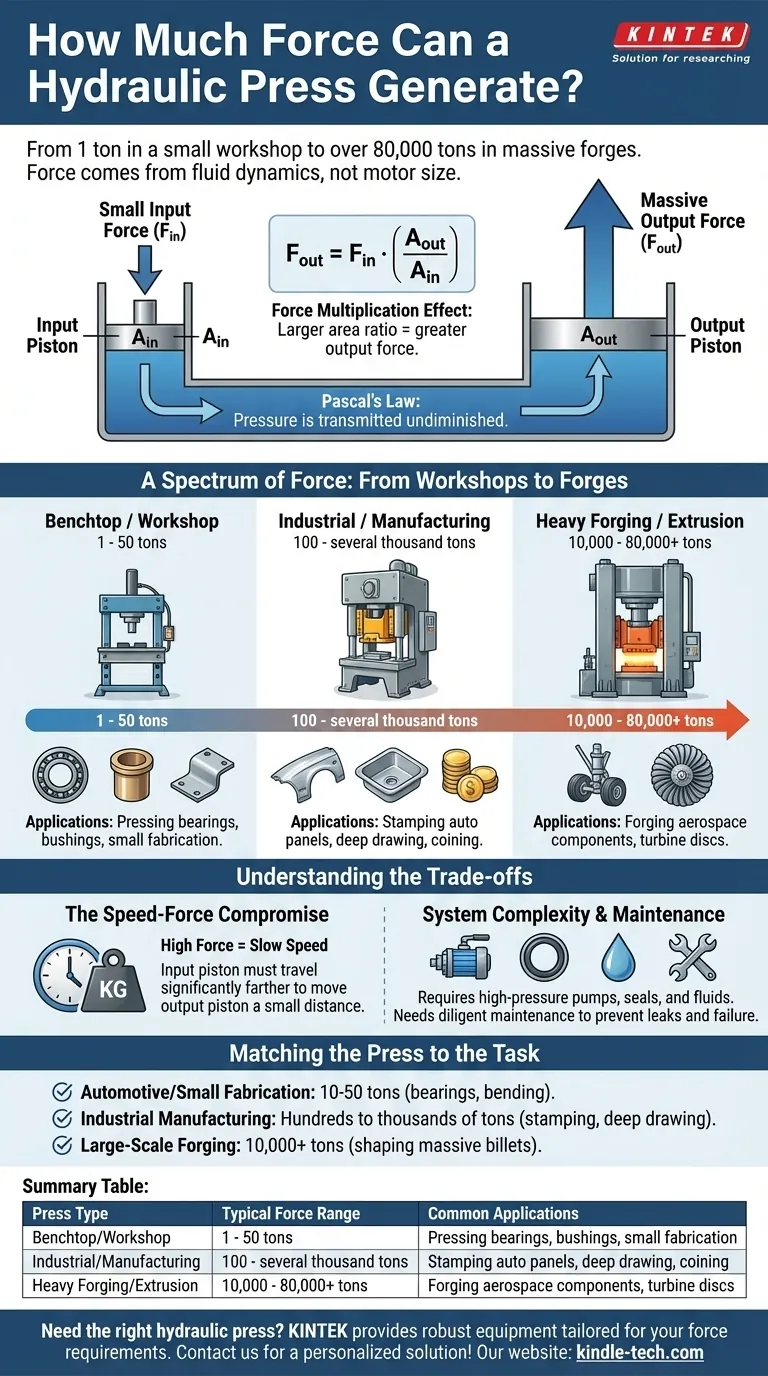

The force a hydraulic press can generate is immense, ranging from a single ton in a small workshop press to over 80,000 tons in the largest industrial forges. This force is not limited by the machine's motor but by the core principles of fluid dynamics, specifically the ratio of piston sizes and the pressure capacity of the hydraulic system.

The power of a hydraulic press comes from a simple, elegant principle known as Pascal's Law. It achieves massive force multiplication by applying a small amount of force to a small piston, which transmits pressure through an incompressible fluid to a much larger piston, generating a proportionally larger output force.

The Principle Behind the Power: Pascal's Law

The incredible force of a hydraulic press isn't magic; it's a direct application of fundamental fluid mechanics. Understanding this principle is key to understanding the machine's capabilities.

What is Pascal's Law?

Pascal's Law states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In a hydraulic system, this means the pressure under the small input piston is the exact same as the pressure exerted on the large output piston.

The Force Multiplication Effect

The system uses two pistons of different sizes connected by a cylinder filled with hydraulic fluid. Force is applied to the small "input" piston, creating pressure in the fluid.

Because pressure equals Force divided by Area (P = F/A), that same pressure acting on the larger "output" piston generates a much greater force. If the output piston has 100 times the surface area of the input piston, the output force will be 100 times greater.

The Core Formula

The relationship is elegantly simple: F_out = F_in * (A_out / A_in).

Here, F_out is the output force, F_in is the input force, A_out is the area of the output piston, and A_in is the area of the input piston. This ratio of areas is the source of the press's power.

A Spectrum of Force: From Workshops to Forges

Hydraulic presses are not one-size-fits-all. Their force ratings are directly tied to their intended application, creating a vast range of sizes and capabilities.

Benchtop and Workshop Presses

These are the most common types of presses, often found in automotive repair shops and small fabrication facilities. They typically range from 1 to 50 tons of force and are used for tasks like pressing bearings, bushings, and bending smaller metal parts.

Industrial and Manufacturing Presses

Moving into factory settings, industrial presses deliver forces from 100 to several thousand tons. These machines are workhorses for tasks like stamping automotive body panels, deep-drawing metal sinks, and coining operations.

Heavy Forging and Extrusion Presses

At the apex of hydraulic power are the massive forging presses. These machines can generate from 10,000 to over 80,000 tons of force. They are used to forge massive metal ingots into critical components for the aerospace, defense, and energy sectors, such as aircraft landing gear or turbine discs.

Understanding the Trade-offs

The immense force multiplication of a hydraulic press does not come without compromises. These are inherent to the physics of the system.

The Speed-Force Compromise

To move the large output piston a certain distance, a much larger volume of fluid is required than what is displaced by the small input piston.

This means the input piston must travel a significantly greater distance to move the output piston a very small amount. The trade-off is clear: high force comes at the cost of slow speed.

System Complexity and Maintenance

Hydraulic systems rely on high-pressure pumps, durable seals, and specialized fluids to operate. This introduces a level of complexity not found in simpler mechanical presses.

Leaks, fluid contamination, and seal failure are potential points of failure that require diligent maintenance to prevent downtime and ensure safe operation.

Matching the Press to the Task

Choosing or understanding a hydraulic press requires matching its force capability to the intended goal.

- If your primary focus is automotive repair or small fabrication: A press in the 10 to 50-ton range is typically more than sufficient for tasks like pressing bearings or bending metal.

- If your primary focus is industrial manufacturing: Presses in the hundreds or thousands of tons are required for processes like stamping steel body panels or deep drawing.

- If your primary focus is large-scale forging: You are operating in the realm of specialized heavy presses, with forces exceeding 10,000 tons for shaping massive metal billets.

Ultimately, the hydraulic press is a testament to how a simple physical law can be engineered to create machines of almost unbelievable power.

Summary Table:

| Press Type | Typical Force Range | Common Applications |

|---|---|---|

| Benchtop/Workshop | 1 - 50 tons | Pressing bearings, bushings, small fabrication |

| Industrial/Manufacturing | 100 - several thousand tons | Stamping auto panels, deep drawing, coining |

| Heavy Forging/Extrusion | 10,000 - 80,000+ tons | Forging aerospace components, turbine discs |

Need the right hydraulic press for your lab or production needs? KINTEK specializes in providing robust lab equipment and consumables, including hydraulic presses tailored for your specific force requirements. Our experts can help you select the perfect machine to enhance your efficiency and achieve precise results. Contact us today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis