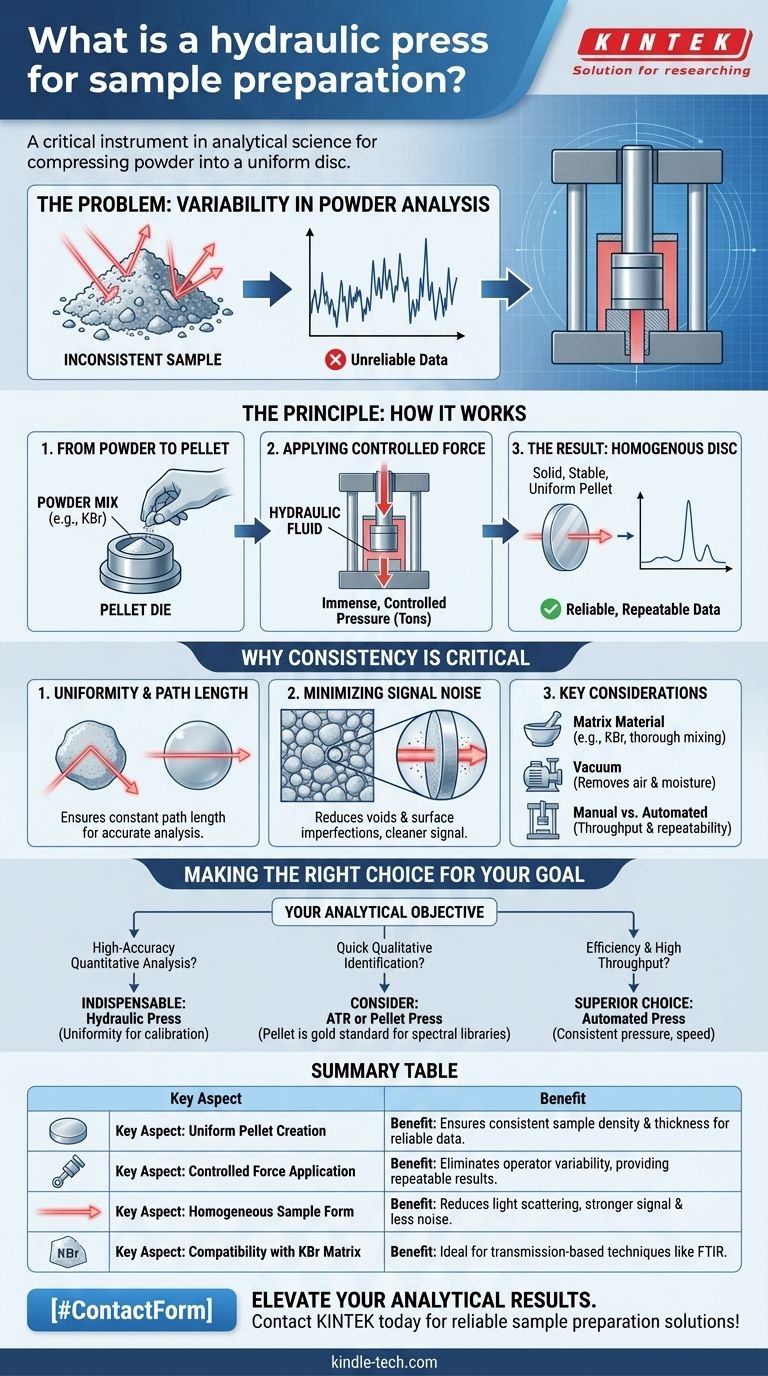

In the world of analytical science, a hydraulic press for sample preparation is a laboratory instrument that applies immense, controlled force to compress a powdered sample into a solid, uniform disc or pellet. This is a critical step for many analytical techniques, most notably Fourier-transform infrared (FTIR) spectroscopy, as it creates a consistent sample form that ensures measurements are both reliable and repeatable.

A hydraulic press solves a fundamental problem in sample analysis: variability. By converting a loose powder into a dense, homogenous pellet, it eliminates inconsistencies that would otherwise compromise the quality and reliability of your analytical data.

The Principle: How a Hydraulic Press Creates the Perfect Sample

A hydraulic press operates on a simple yet powerful principle to transform a difficult-to-analyze powder into an ideal solid sample.

From Powder to Pellet

The process begins by placing a small amount of the powdered sample, often mixed with a transparent salt like Potassium Bromide (KBr), into a specialized mold called a pellet die.

Applying Controlled Force

The press uses hydraulic fluid to amplify a relatively small manual force into a massive compressive force, often several tons. This force is applied evenly and slowly to the die via a plunger.

The Result: A Homogenous Disc

This immense pressure forces the powder particles to fuse together, eliminating air pockets and creating a solid, mechanically stable pellet. The resulting disc is often semi-transparent, which is ideal for transmission-based analysis.

Why Consistency Is Critical for Analysis

The primary goal of using a press is not just to make a solid disc, but to achieve a level of consistency that is impossible with loose powder. This consistency directly impacts the quality of your results.

The Problem with Inconsistent Samples

A loose powder has a highly variable density and particle size. When an analytical beam (like an infrared laser) passes through it, the light scatters unpredictably, and the effective path length changes from one sample to the next, leading to inaccurate and non-repeatable measurements.

Uniformity and Path Length

A properly pressed pellet has a uniform thickness and density. This standardization ensures the analytical beam interacts with the same amount of sample material every single time, a principle known as a constant path length, which is fundamental for accurate analysis.

Minimizing Signal Noise

Compacting the powder under high pressure significantly reduces voids and surface imperfections that cause light scattering. Less scattering results in a stronger, clearer signal reaching the detector, which dramatically improves the signal-to-noise ratio and produces cleaner data.

Understanding the Trade-offs and Key Considerations

While powerful, the pellet pressing technique requires attention to detail and is not a universal solution for all analytical challenges.

The Need for a Matrix Material

For techniques like FTIR, the sample is rarely pressed alone. It must be thoroughly ground and mixed with an IR-transparent matrix material (most commonly KBr). This step adds time and requires careful weighing to ensure a known concentration.

The Importance of Vacuum

For the highest-quality pellets, especially for quantitative analysis, the die is often connected to a vacuum pump during pressing. This removes trapped air and, more importantly, moisture, which can absorb infrared light and interfere with the measurement.

Manual vs. Automated Presses

Manual presses are cost-effective and common, but throughput is limited, and the applied force can vary between operators. Automated or powered hydraulic presses offer superior repeatability and speed, making them ideal for quality control labs with high sample volumes.

Making the Right Choice for Your Goal

Integrating a hydraulic press into your workflow is a decision that should be aligned with your specific analytical objectives.

- If your primary focus is high-accuracy quantitative analysis: A hydraulic press is indispensable. The sample uniformity it provides is essential for creating the reliable calibration standards needed for quantification.

- If your primary focus is quick qualitative identification: You can also consider alternative techniques like Attenuated Total Reflectance (ATR), but pellet pressing remains the gold standard for building high-quality spectral libraries.

- If your primary focus is efficiency and high throughput: An automated hydraulic press is the superior choice, as it guarantees consistent pressure application and significantly reduces the time required per sample.

Ultimately, mastering the use of a hydraulic press is a direct investment in the quality and trustworthiness of your analytical work.

Summary Table:

| Key Aspect | Benefit for Analysis |

|---|---|

| Uniform Pellet Creation | Ensures consistent sample density and thickness for reliable data. |

| Controlled Force Application | Eliminates operator variability, providing repeatable results. |

| Homogeneous Sample Form | Reduces light scattering, leading to a stronger signal and less noise. |

| Compatibility with KBr Matrix | Ideal for transmission-based techniques like FTIR spectroscopy. |

Elevate the accuracy and reliability of your analytical results. A high-quality hydraulic press is fundamental for creating uniform sample pellets for FTIR and other techniques. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable sample preparation solutions. Contact us today to find the perfect press for your accuracy and throughput requirements!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What are the advantages of hydraulic press? High Force, Precision Control & Versatility

- What is the minimum sample required for XRD analysis? Optimize Your Material Analysis

- What are presses used for in manufacturing? The Ultimate Guide to Shaping Materials

- What are the advantages of hydraulic pressure? Harness Immense Force with Simple, Cost-Effective Design

- How does a laboratory hydraulic press contribute to the molding phase of Cu/WC? Precision Compacts for Composite Success

- What are the forces in a hydraulic press? Harnessing Immense Compressive Power

- How does axial pressure influence Al2O3-TiCN/Co-Ni ceramics? Optimize Densification and Microstructure

- What are the basics of a hydraulic press? Unlock the Power of Force Multiplication