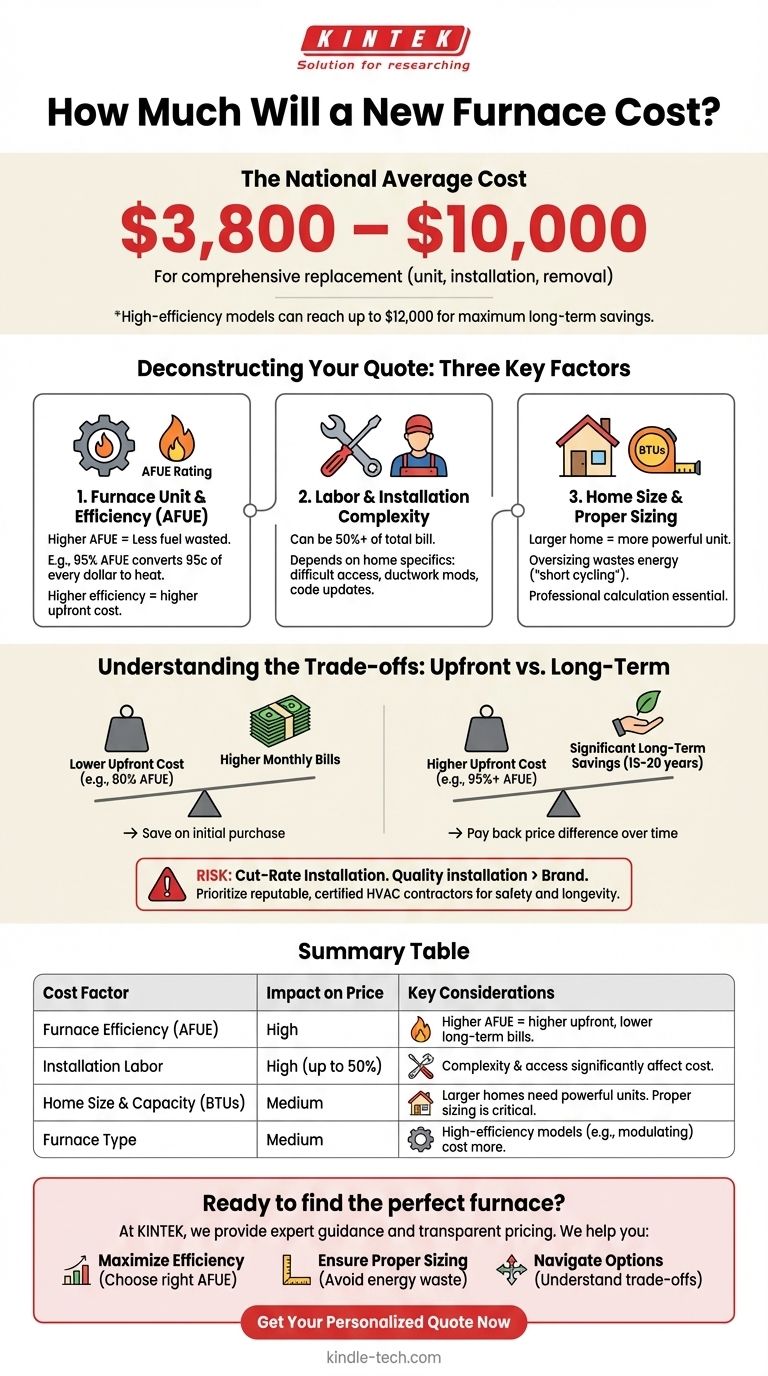

The national average cost for a new furnace typically falls between $3,800 and $10,000 for a comprehensive replacement. This price includes the unit itself, professional installation, and removal of your old equipment. For high-efficiency models designed for maximum long-term savings, you can expect the total cost to reach as high as $12,000.

The final price you pay is a combination of three key factors: the furnace unit's efficiency rating, the complexity of the installation labor, and the specific heating requirements of your home. Understanding these components is essential to evaluating any quote you receive.

Deconstructing Your Furnace Replacement Quote

The price range for a new furnace is wide because you are not just buying an appliance; you are paying for a complex system installation. The final invoice is typically split between equipment and labor costs.

The Furnace Unit and Its Efficiency (AFUE)

The single biggest factor in the equipment cost is its Annual Fuel Utilization Efficiency (AFUE) rating. This is a government-mandated percentage that measures how efficiently the furnace converts fuel into heat.

A higher AFUE rating means less fuel is wasted. For example, a 95% AFUE furnace converts 95 cents of every dollar spent on fuel into heat for your home, while 5 cents are lost through exhaust.

This efficiency level directly correlates with price. Standard-efficiency models (around 80% AFUE) are the least expensive upfront. High-efficiency models (95% AFUE or higher) command a premium price but deliver significant long-term savings on your energy bills.

Labor and Installation Complexity

Often overlooked, labor can account for 50% or more of your total bill. This cost is not standardized and depends entirely on the specifics of your home.

Factors that increase labor costs include difficult access to the furnace location (tight crawl spaces or attics), necessary modifications to existing ductwork, and required electrical or gas line updates to meet current building codes.

Home Size and Proper Furnace Sizing

A larger home requires a more powerful furnace, measured in BTUs (British Thermal Units), which will inherently cost more.

However, simply buying the biggest unit is a critical mistake. An oversized furnace will "short cycle"—turning on and off frequently—which wastes energy, creates uneven heating, and causes premature wear on components. A professional installer must perform a calculation to determine the exact size your home needs.

Understanding the Trade-offs

Choosing a furnace involves balancing initial investment against future operating costs. There is no single "best" choice, only the right choice for your priorities.

Upfront Cost vs. Long-Term Savings

This is the central trade-off. A less expensive, 80% AFUE furnace will save you money on the initial purchase.

A high-efficiency 95%+ AFUE model will cost more upfront but will reduce your monthly heating bills for the 15-20 year lifespan of the unit, often paying back the initial price difference over time.

The Risk of a Cut-Rate Installation

The quality of the installation is more important than the brand of the furnace. An improperly installed high-end furnace will perform poorly and fail early.

Always prioritize a reputable, certified HVAC contractor over a lower price from an unverified source. A proper installation ensures safety, efficiency, and longevity of the system.

Making the Right Choice for Your Goal

To select the best furnace for your situation, clarify your primary objective.

- If your primary focus is the lowest possible upfront cost: Select a standard 80% AFUE furnace, but budget for higher monthly energy bills.

- If your primary focus is long-term savings and energy efficiency: Invest in a high-efficiency model (95%+ AFUE), as the higher initial cost will be offset by lower fuel bills.

- If your primary focus is a balance of value and performance: A mid-range 90-92% AFUE furnace can provide a good compromise, but be sure to get multiple quotes to ensure the installation cost is fair.

Armed with this understanding, you can confidently evaluate contractor quotes and select a furnace that meets both your home's needs and your financial goals.

Summary Table:

| Cost Factor | Impact on Price | Key Considerations |

|---|---|---|

| Furnace Efficiency (AFUE) | High | Higher AFUE (95%+) = higher upfront cost, lower long-term bills. Standard (80% AFUE) = lower upfront cost. |

| Installation Labor | High (Up to 50% of total) | Complexity, ductwork modifications, and home access significantly affect cost. |

| Home Size & Furnace Capacity (BTUs) | Medium | Larger homes need more powerful (and expensive) units. Proper sizing is critical for efficiency. |

| Furnace Type | Medium | High-efficiency models (e.g., modulating) cost more than standard single-stage furnaces. |

Ready to find the perfect furnace for your home and budget?

At KINTEK, we understand that selecting the right heating system is a significant investment. Our team is here to provide you with expert guidance and transparent pricing on high-quality lab equipment and environmental control systems.

We help you:

- Maximize Efficiency: Choose the right AFUE rating for long-term savings.

- Ensure Proper Sizing: Get a unit that fits your space perfectly to avoid energy waste.

- Navigate Your Options: Understand the trade-offs between upfront cost and performance.

Contact us today for a personalized consultation and let us help you achieve optimal comfort and efficiency.

Get Your Personalized Quote Now

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a muffle furnace? Achieve Pure, Contamination-Free Heating

- Does ceramic break with heat? The Real Culprit is Thermal Shock

- What is the concept of muffle furnace? Achieve Clean, Uniform High-Temperature Processing

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- What is a muffle furnace used for in pharma? Ensuring Purity and Regulatory Compliance