Unlike routine maintenance items, a heating element is not replaced on a fixed schedule. It is a component you replace only upon failure. For common residential appliances like electric water heaters, the element is designed to last the life of the unit itself—typically 10 to 15 years—unless a specific malfunction accelerates its demise.

A heating element's lifespan is defined by its operating conditions, not by a calendar. Understanding the factors that lead to failure, such as mineral buildup and usage intensity, is far more valuable than adhering to a generic replacement timeline.

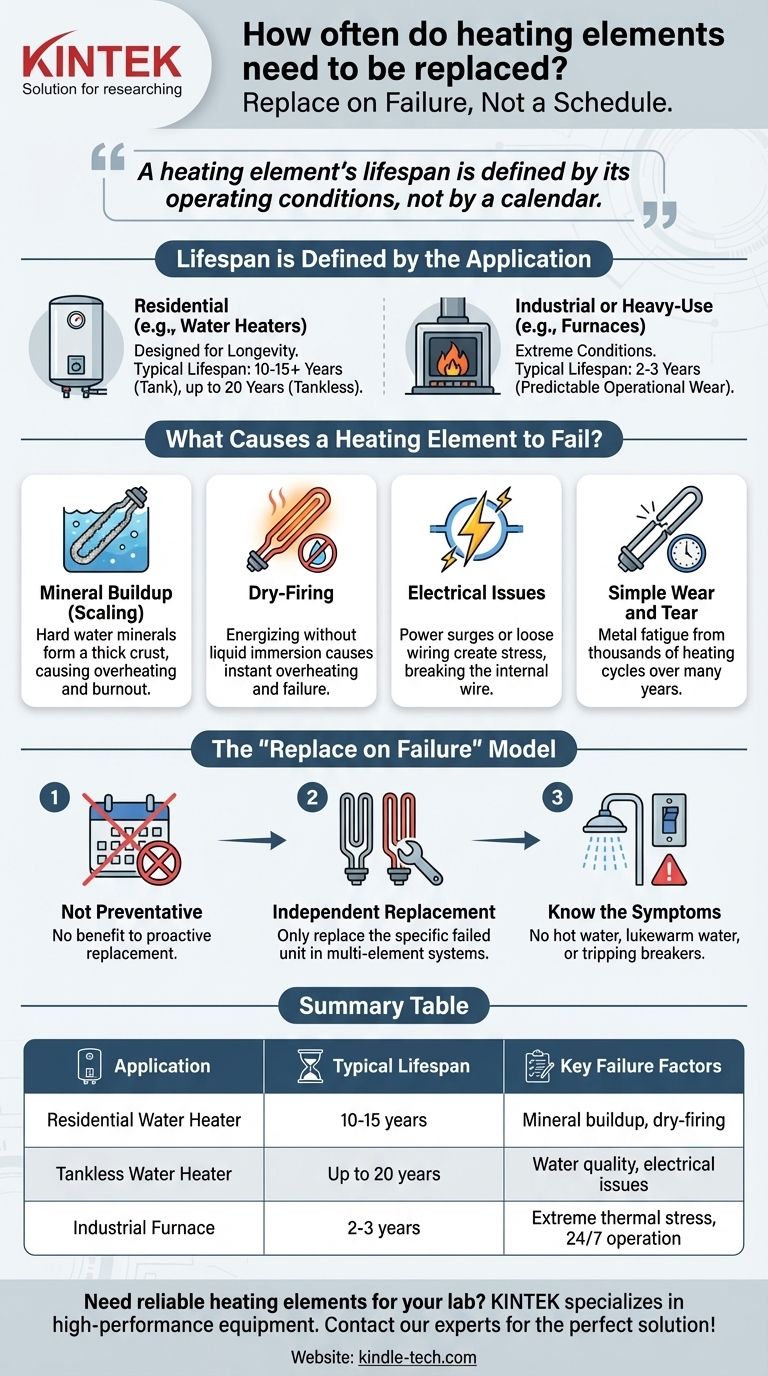

The Lifespan is Defined by the Application

The term "heating element" covers a vast range of components used in everything from household appliances to industrial furnaces. Their expected lifespan is a direct function of their environment and workload.

Residential Appliances (e.g., Water Heaters)

In a standard electric tank water heater, the heating elements are designed for longevity. The target is to match the lifespan of the tank, which is often 10 to 15 years.

For a tankless water heater, which operates differently, the components are generally built to a higher standard, with lifespans potentially reaching 20 years. In these cases, early failure is always a symptom of a problem, not a scheduled end-of-life.

Industrial or Heavy-Use Equipment

The calculus changes completely under extreme conditions. A heating element in a vacuum furnace running 24/7 is subjected to immense thermal stress.

In this type of high-demand industrial setting, it is common to replace heating elements on a much shorter cycle, often every two to three years, as part of predictable operational wear.

What Causes a Heating Element to Fail?

Failure is rarely a matter of simple old age. Specific, identifiable factors almost always cause an element to burn out prematurely. Understanding these is key to maximizing lifespan.

Mineral Buildup (Scaling)

This is the most common cause of failure in water heaters. Hard water contains dissolved minerals like calcium and magnesium, which precipitate out and form a thick crust of scale on the element.

This scale acts as an insulator, forcing the element to work much harder and run hotter to heat the surrounding water. This excessive internal temperature eventually causes the element to overheat and burn out.

Dry-Firing

A heating element is designed to be immersed in a liquid to dissipate its heat. If the water tank is drained for maintenance and the power is not turned off, the element can be accidentally energized in open air.

This condition, known as dry-firing, causes the element to overheat and fail in a matter of seconds.

Electrical Issues

Power surges, improper voltage, or loose wiring can create electrical stress on the element. This can cause the internal resistive wire to break or short out, leading to immediate failure.

Simple Wear and Tear

Over thousands of heating and cooling cycles across many years, the metal of the element can eventually fatigue and break. This is a true end-of-life failure, but it typically only occurs after a decade or more of normal service.

Understanding the "Replace on Failure" Model

Heating elements are a reactive repair item, not a proactive maintenance part. This approach has important practical and financial implications.

It's Not a Preventative Task

There is no benefit to replacing a functional heating element. A new element will not perform "better" than an old one that is still working correctly. Proactive replacement is an unnecessary expense.

The Benefit of Independent Replacement

Many appliances, like electric water heaters, use two heating elements (an upper and a lower). When one fails, you only need to replace that specific unit.

There is no technical reason to replace both elements at the same time if one is still functioning properly. This targeted approach minimizes repair costs.

How to Know It Has Failed

The symptoms of a failed element are usually obvious. They include a complete lack of hot water, lukewarm water that doesn't get hot enough, or a circuit breaker that repeatedly trips when the appliance is trying to heat.

Making the Right Decision for Your Goal

Instead of worrying about a timeline, focus on the symptoms and causes of failure. This will give you true control over your equipment's maintenance.

- If your primary focus is maximum lifespan: Concentrate on preventing the root causes, especially by flushing your water heater tank annually to minimize mineral scale buildup.

- If your primary focus is diagnosing a problem: Use a multimeter to test the element for electrical continuity. This definitively proves whether the element has failed before you purchase a replacement.

- If your primary focus is cost-effective repair: Remember that in a multi-element system, you typically only need to identify and replace the specific element that has failed.

By focusing on the operating conditions rather than a calendar, you can effectively manage your equipment and address failures with confidence.

Summary Table:

| Application | Typical Lifespan | Key Failure Factors |

|---|---|---|

| Residential Water Heater | 10-15 years | Mineral buildup (scaling), dry-firing |

| Tankless Water Heater | Up to 20 years | Water quality, electrical issues |

| Industrial Furnace | 2-3 years | Extreme thermal stress, 24/7 operation |

Need a reliable heating element or expert advice for your laboratory equipment? KINTEK specializes in high-performance lab equipment and consumables, ensuring your heating systems operate at peak efficiency with minimal downtime. Our products are built to withstand demanding conditions, providing consistent results for your critical applications. Contact our experts today to find the perfect solution for your lab's needs!

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab

- What are the heating elements for high temperature furnaces? Select the Right Element for Your Atmosphere

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What is the temperature range of molybdenum disilicide heating elements? Choose the Right Grade for Your High-Temp Needs

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C