In RF sputtering, plasma is generated by applying a high-frequency alternating electric field to a low-pressure inert gas, such as argon. This rapidly oscillating field energizes free electrons within the chamber, causing them to collide with and strip electrons from the neutral gas atoms. This process, known as impact ionization, creates a self-sustaining cloud of positive ions and free electrons which we recognize as plasma.

Unlike DC sputtering, which only works for conductive materials, RF sputtering uses an alternating electric field. This core difference prevents catastrophic charge buildup on insulating targets, allowing the plasma to be sustained and sputtering to occur continuously.

The Fundamental Steps to Plasma Ignition

Creating a stable plasma for RF sputtering is a precise, multi-step process. It begins in a vacuum and ends with a self-sustaining chain reaction.

Establishing the Environment

First, the sputtering chamber is sealed and pumped down to a high vacuum to remove contaminants like oxygen and water vapor. A pure, inert gas—most commonly argon (Ar)—is then introduced into the chamber and maintained at a specific low pressure. This controlled environment ensures the subsequent plasma is composed almost entirely of the desired gas.

The Role of Initial Free Electrons

Within this low-pressure gas, there are always a few stray, or free, electrons present from natural cosmic radiation or thermal energy. These initial electrons are the essential "seeds" for igniting the plasma.

Applying the Radio Frequency Field

An RF power supply, typically operating at a federally mandated frequency of 13.56 MHz, is applied to an electrode known as the target. This creates a rapidly alternating electric field within the chamber. Because electrons are thousands of times lighter than argon atoms, they are the only particles that can respond to this high-frequency oscillation, accelerating back and forth rapidly.

The Cascade of Ionization

As these energized electrons oscillate, they collide with the large, stationary neutral argon atoms. If an electron has gained enough kinetic energy from the field, its collision will be "inelastic," knocking an electron out of the argon atom's orbital shell.

The result of this collision is one positive argon ion (Ar+) and two free electrons. These two electrons are then accelerated by the RF field, leading to more collisions and creating more ions and electrons. This avalanche effect is a chain reaction that rapidly creates the dense, glowing plasma required for sputtering.

Why an Alternating Field is Crucial

The use of a Radio Frequency (RF) field is not arbitrary; it is the specific solution to a fundamental problem that makes sputtering insulators possible.

The Failure of DC Sputtering with Insulators

In a simple Direct Current (DC) system, a static negative voltage is applied to the target. This attracts positive argon ions, which strike the target and sputter material. This works perfectly for a conductive metal target, which can dissipate the positive charge delivered by the ions.

However, if the target is an insulator (like quartz or alumina), the positive charge from the arriving ions accumulates on its surface. This buildup of positive charge, known as "target poisoning," quickly repels any more incoming positive ions, neutralizing the sputtering process and extinguishing the plasma.

The RF Solution: Neutralizing the Charge

The alternating RF field solves this problem with each cycle.

During the part of the cycle when the target is negative, it attracts the positive Ar+ ions, and sputtering occurs as intended.

During the next part of the cycle when the target becomes positive, it powerfully attracts the highly mobile, lightweight electrons from the plasma. These electrons flood the target surface, neutralizing the positive charge that built up during the sputtering phase. This cleanses the target surface every cycle, allowing the process to continue.

The Self-Biasing Effect

Because electrons are so much more mobile than ions, far more electrons strike the target during its brief positive phase than ions do during its longer negative phase. The net result is that the insulating target surface develops an overall negative DC bias, even though the applied voltage is AC. This negative bias is what ensures a continuous, strong attraction for the positive ions, driving the sputtering process effectively.

Understanding the Trade-offs

While RF sputtering is highly versatile, it comes with certain trade-offs compared to other methods.

Lower Deposition Rates

For conductive materials, RF sputtering is generally slower than DC sputtering. This is because significant ion bombardment and sputtering only occurs during the portion of the RF cycle when the target is sufficiently negative.

Increased System Complexity

RF systems require more sophisticated and expensive equipment. An RF power supply and an impedance matching network are necessary to ensure the power is transferred efficiently into the plasma rather than being reflected back to the source. This adds a layer of complexity and cost not present in simpler DC setups.

Plasma Confinement

In its basic form, RF plasma can be diffuse, leading to unwanted heating of the chamber and substrate. This is why many modern systems combine RF power with magnetron technology. Magnets behind the target trap electrons near its surface, dramatically increasing the ionization efficiency and creating a denser plasma where it's needed most.

Making the Right Choice for Your Material

Your choice of sputtering technique should be dictated entirely by the electrical properties of the material you wish to deposit.

- If your primary focus is depositing conductive materials (metals, alloys, TCOs): DC or Pulsed-DC magnetron sputtering is almost always the superior choice for its higher deposition rates and simpler setup.

- If your primary focus is depositing insulating materials (oxides like SiO₂, Al₂O₃, or nitrides like Si₃N₄): RF sputtering is the essential and correct method, as its alternating field is the only practical way to prevent fatal charge accumulation on the target.

- If your primary focus is controlling film stress or depositing compound films reactively: Combining RF or pulsed-DC power sources with careful process control is necessary to achieve the desired film properties.

Understanding the role of the alternating field is the key to mastering RF sputtering and successfully depositing high-quality insulating thin films.

Summary Table:

| Key Aspect | Description |

|---|---|

| Gas Used | Argon (Ar) |

| Frequency | 13.56 MHz |

| Core Process | Impact ionization via electron-atom collisions |

| Key Advantage | Prevents charge buildup on insulating targets |

| Result | Self-sustaining plasma for thin film deposition |

Need to deposit high-quality insulating films like SiO₂ or Al₂O₃?

KINTEK specializes in RF sputtering systems and lab equipment, providing the precise plasma control required for your advanced materials research. Our solutions help you achieve uniform, high-purity thin films with reliable performance.

Contact our experts today to discuss how our RF sputtering technology can enhance your laboratory's capabilities!

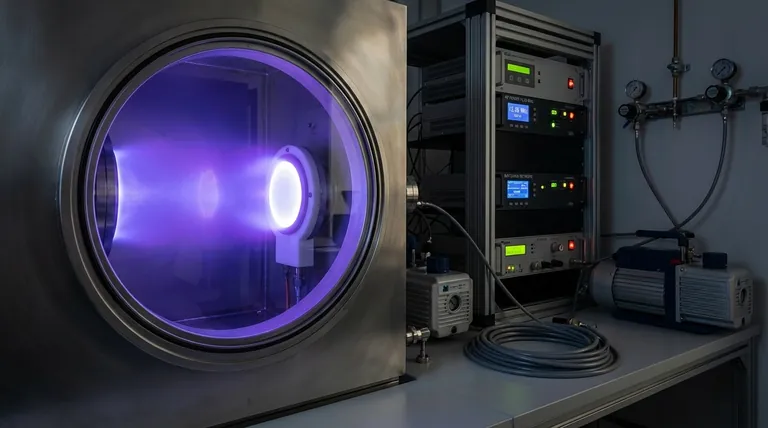

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What is the working principle of chemical vapor deposition? Grow Superior Thin Films from Gas

- What is plasma in RF sputtering? The Engine of Thin-Film Deposition

- What are the design priorities for HP-MOCVD rotating susceptors? Optimize Material Stability & Purity at 20+ atm

- What role does a vacuum Chemical Vapor Deposition (CVD) system play in the production of large-area graphene films?

- What is the vapor deposition of metals? Build Superior, High-Purity Metal Coatings

- What does chemical vapor deposition do? Create High-Performance Thin Films for Advanced Manufacturing

- What are the application of thin films in optics? Control Light with Nanometer Precision

- What is the construction and working of chemical vapour deposition? A Guide to High-Performance Thin Film Coating