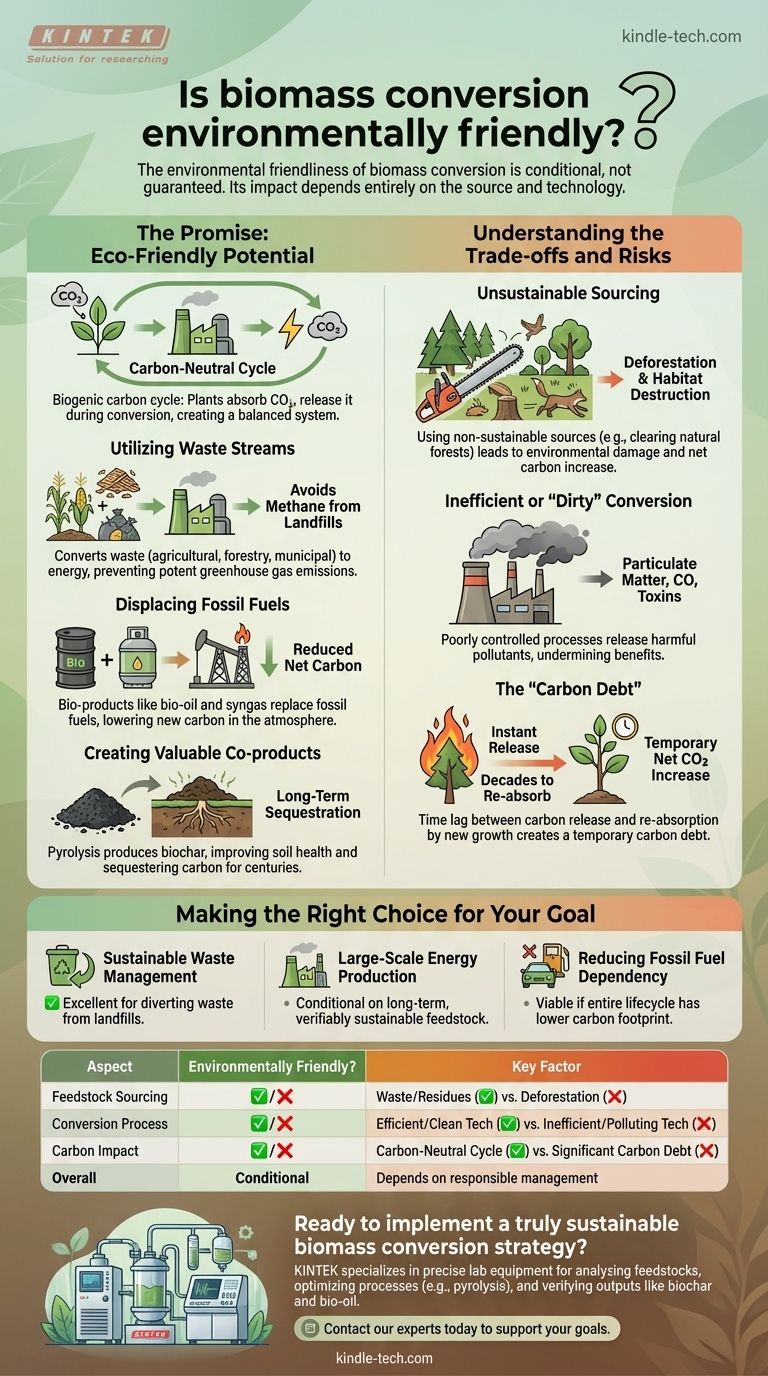

The environmental friendliness of biomass conversion is conditional, not guaranteed. While it can be a powerful tool for reducing greenhouse gas emissions and managing waste, its actual impact depends entirely on the source of the biomass and the technology used for conversion.

Biomass conversion offers a path to renewable energy, but its "green" credentials are not inherent. The entire process must be scrutinized, from how the raw material is sourced to how efficiently it is converted, to determine if it is a net positive for the environment.

The Promise: How Biomass Can Be Eco-Friendly

The core concept behind biomass energy is its role within the biogenic carbon cycle. Plants absorb CO2 from the atmosphere, and when that biomass is converted to energy, the same CO2 is released, creating a theoretically balanced, or carbon-neutral, system.

Utilizing Waste Streams

The most compelling environmental case for biomass involves using materials that would otherwise be discarded. This includes agricultural residues, forestry byproducts, and organic municipal waste.

Converting this waste into energy avoids the release of methane, a potent greenhouse gas that is emitted when organic matter decomposes in landfills.

Displacing Fossil Fuels

Products derived from biomass conversion, such as bio-oil and syngas, can directly replace fossil fuels like oil and natural gas.

This substitution reduces the net amount of new carbon being introduced into the atmosphere from burning ancient, sequestered fossil sources.

Creating Valuable Co-products

Certain conversion processes, like pyrolysis, produce biochar—a stable, carbon-rich material.

When added to soil, biochar can improve soil health and effectively sequester carbon for hundreds or thousands of years, removing it from the atmospheric cycle.

Understanding the Trade-offs and Risks

The potential benefits of biomass are significant, but they can be completely negated if the process is managed poorly. The risks are not trivial and must be the primary consideration in any biomass project.

The Critical Issue of Feedstock Sourcing

The single greatest risk is the use of unsustainable biomass sources.

If demand for biomass leads to the clearing of natural forests or the conversion of land that should be used for food crops, the environmental damage is immediate. This results in deforestation, habitat destruction, and a net increase in atmospheric carbon.

Inefficient or "Dirty" Conversion

The conversion technology itself matters. An inefficient or poorly controlled process can release harmful pollutants into the atmosphere.

Incomplete combustion can produce particulate matter, carbon monoxide, and other air toxins that undermine the environmental benefits of displacing fossil fuels.

The "Carbon Debt"

Even when using "sustainable" sources like dedicated forestry, there is a time lag. Burning a tree releases its stored carbon instantly.

It takes decades for a new tree to grow and re-absorb that same amount of carbon. This period is known as the carbon debt, during which there is a temporary net increase in atmospheric CO2.

Making the Right Choice for Your Goal

To determine if a biomass conversion strategy is environmentally sound, you must first define its primary objective.

- If your primary focus is sustainable waste management: Biomass conversion is an excellent and often highly beneficial tool for diverting agricultural, forestry, or municipal waste from landfills.

- If your primary focus is large-scale energy production: The environmental viability depends entirely on securing a long-term, verifiably sustainable feedstock that does not compete with food production or natural ecosystems.

- If your primary focus is reducing fossil fuel dependency: Biomass is a viable alternative, but only if the entire lifecycle—from harvesting to transport to conversion—is proven to have a lower carbon footprint than the fossil fuel it replaces.

Ultimately, biomass conversion is a tool, and its impact is determined by how responsibly it is used.

Summary Table:

| Aspect | Environmentally Friendly? | Key Factor |

|---|---|---|

| Feedstock Sourcing | ✅ If using waste/ residues | ❌ If causing deforestation |

| Conversion Process | ✅ With efficient, clean tech | ❌ With inefficient, polluting tech |

| Carbon Impact | ✅ Carbon-neutral cycle | ❌ Significant carbon debt |

| Overall | Conditional | Depends on responsible management |

Ready to implement a truly sustainable biomass conversion strategy?

Choosing the right lab equipment is the first step to ensuring your process is efficient, clean, and environmentally sound. KINTEK specializes in the precise lab equipment and consumables needed for analyzing biomass feedstocks, optimizing conversion processes like pyrolysis, and verifying the quality of outputs like biochar and bio-oil.

Let us help you make a positive environmental impact. Contact our experts today to discuss how our solutions can support your sustainable energy and waste management goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Performance Laboratory Freeze Dryer for Research and Development

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the different types of pyrolysis machines? Choose the Right System for Your Output