The question of whether silicon carbide is "better" than ceramic is based on a common misunderstanding. Silicon carbide (SiC) is not a separate category of material; it is a high-performance member of the technical ceramic family. The real question is how SiC compares to other common ceramics, like alumina or zirconia, and for which specific applications its unique properties make it the superior choice.

The term "ceramic" encompasses a vast range of materials. Silicon carbide is an advanced, or technical, ceramic prized for its exceptional hardness and thermal conductivity, but its high cost and brittleness mean it is not universally "better" than more common ceramics like alumina for every task.

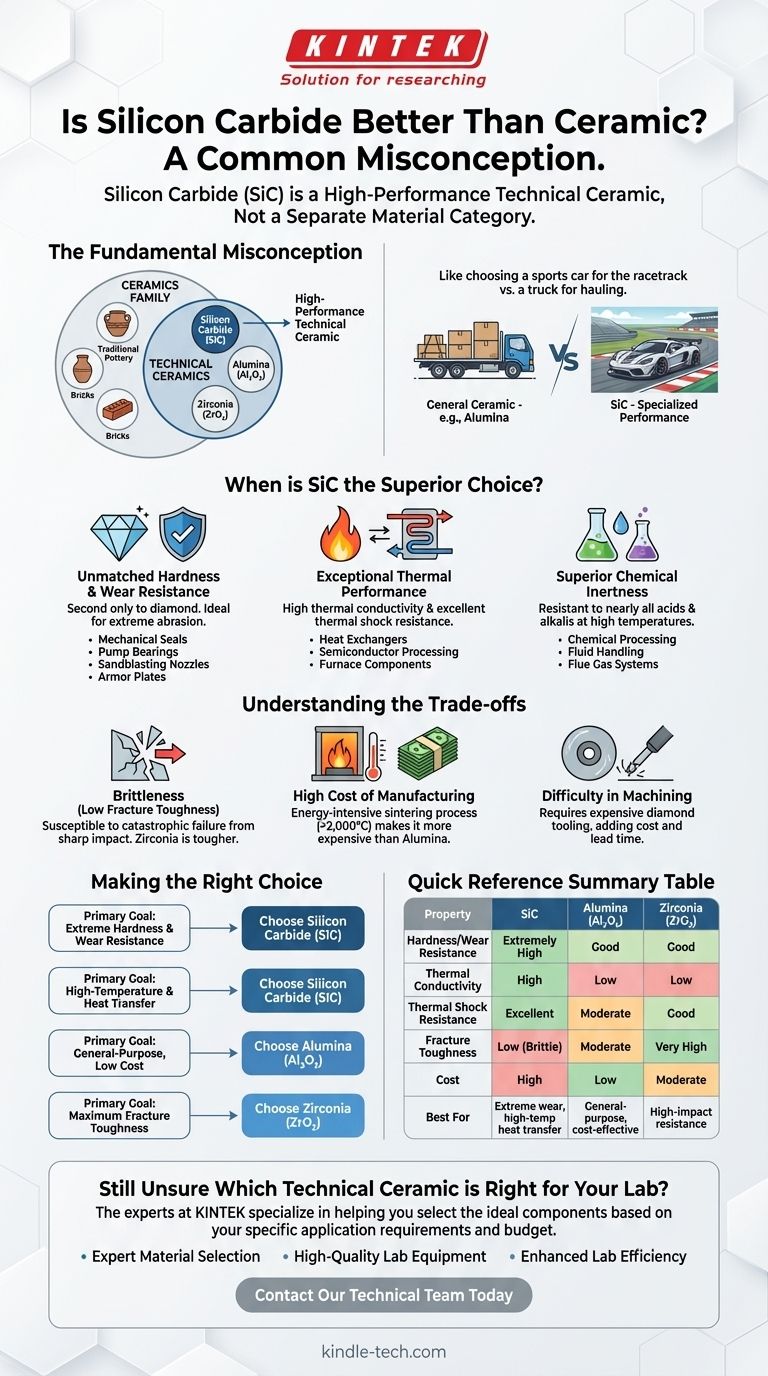

The Fundamental Misconception: Silicon Carbide Is a Ceramic

The most critical concept to grasp is that you are not choosing between silicon carbide and ceramic, but rather selecting a specific type of ceramic for a job. Comparing SiC to "ceramic" is like asking if a sports car is better than a "vehicle." A sports car is excellent for a racetrack, but a truck is better for hauling cargo.

What Defines a "Ceramic"?

A ceramic is an inorganic, non-metallic solid prepared by the action of heat and subsequent cooling. This broad category includes everything from traditional pottery and bricks to advanced, high-purity materials engineered for specific technical functions.

Where Silicon Carbide Fits In

Silicon carbide is a technical ceramic, also known as an advanced or engineering ceramic. These materials are developed to exhibit highly specialized properties. SiC is often compared against other technical ceramics like Alumina (Aluminum Oxide), a cost-effective and versatile workhorse, and Zirconia, known for its exceptional fracture toughness.

When is Silicon Carbide the Superior Choice?

Silicon carbide's properties make it the leading candidate for some of the most demanding industrial and high-tech applications. It excels where other materials, including other ceramics, would fail.

Unmatched Hardness and Wear Resistance

Silicon carbide is one of the hardest commercially available materials, second only to diamond. This gives it phenomenal resistance to abrasion, erosion, and sliding wear.

This property makes it the ideal choice for components like mechanical seals, pump bearings, sandblasting nozzles, and ballistic armor plates.

Exceptional Thermal Performance

Most ceramics are thermal insulators, but SiC is a notable exception with high thermal conductivity. It can draw heat away from a source quickly while also withstanding extremely high temperatures without degrading.

Its low thermal expansion and high strength also give it excellent thermal shock resistance, meaning it can endure rapid temperature changes without cracking. This is crucial for parts in heat exchangers, semiconductor wafer processing, and furnace components.

Superior Chemical Inertness

Silicon carbide demonstrates outstanding resistance to nearly all acids and alkalis, even at high temperatures. It does not corrode or degrade in harsh chemical environments.

This makes it invaluable for components used in chemical processing, fluid handling, and flue gas desulfurization systems.

Understanding the Trade-offs: When to Choose Other Ceramics

Despite its elite performance, SiC is not always the right answer. Its specialized nature comes with significant trade-offs that make other ceramics more suitable for different applications.

The Challenge of Brittleness

Like most extremely hard materials, silicon carbide is brittle. It has low fracture toughness, meaning it can be susceptible to catastrophic failure from a sharp impact, whereas a tougher ceramic like Zirconia might survive.

The High Cost of Manufacturing

Producing dense, high-purity silicon carbide parts is an energy-intensive process called sintering, which requires extremely high temperatures (often >2,000°C) and pressures.

This makes SiC components significantly more expensive than those made from a more common ceramic like Alumina. If the application does not demand SiC's extreme properties, Alumina is often the more economical choice.

Difficulty in Machining

The very hardness that makes SiC excellent for wear resistance also makes it incredibly difficult and expensive to machine into complex final shapes. Grinding and finishing must be done with diamond tooling, adding substantial cost and lead time to a project.

Making the Right Choice for Your Application

Selecting the correct ceramic requires a clear understanding of your primary engineering goal and budget.

- If your primary focus is extreme hardness and wear resistance: Silicon carbide is almost certainly the best technical ceramic for the job.

- If your primary focus is high-temperature performance combined with heat transfer: Silicon carbide's unique thermal conductivity makes it a superior choice over most other ceramics.

- If your primary focus is general-purpose electrical insulation and good mechanical strength at a low cost: Alumina (Aluminum Oxide) is the industry standard and the most practical choice.

- If your primary focus is maximum fracture toughness and resistance to cracking: Zirconia is often a better candidate than the more brittle silicon carbide.

Choosing the right material is a matter of matching specific properties to the demands of your application.

Summary Table:

| Property | Silicon Carbide (SiC) | Alumina (Al₂O₃) | Zirconia (ZrO₂) |

|---|---|---|---|

| Hardness / Wear Resistance | Extremely High | Good | Good |

| Thermal Conductivity | High | Low | Low |

| Thermal Shock Resistance | Excellent | Moderate | Good |

| Fracture Toughness | Low (Brittle) | Moderate | Very High |

| Cost | High | Low | Moderate |

| Best For | Extreme wear, high-temp heat transfer | General-purpose, cost-effective applications | High-impact resistance |

Still Unsure Which Technical Ceramic is Right for Your Lab?

Choosing the right material is critical for the performance and longevity of your lab equipment. The experts at KINTEK specialize in helping laboratories like yours select the ideal components—from furnace elements to crucibles and wear parts—based on your specific application requirements and budget.

We provide:

- Expert Material Selection: Get personalized advice on whether silicon carbide, alumina, zirconia, or another advanced ceramic is the optimal choice for your process.

- High-Quality Lab Equipment & Consumables: Source durable, reliable components that ensure your experiments and processes run smoothly.

- Enhanced Lab Efficiency: The right material minimizes downtime, reduces replacement costs, and improves the accuracy of your results.

Don't let material limitations hold back your research. Contact our technical team today for a consultation and let KINTEK provide the solution you need.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

- Precision Machined Silicon Nitride (SiN) Ceramic Sheet for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- Is silicon carbide heat resistant? Unlock Superior Performance in Extreme Temperatures

- What is the strongest ceramics? Silicon Carbide Leads in Hardness & Thermal Strength

- What is the temperature resistance of silicon carbide? Withstands Extreme Heat Up to 1500°C

- What are the characteristics of SiC? Unlock High-Temp, Hard, and Chemically Inert Performance