While tungsten has the highest melting point of any pure metal, it is not the single most heat-resistant material in all circumstances. True heat resistance is more complex than just a high melting point; it involves a material's ability to maintain its strength and resist chemical degradation, like oxidation, at extreme temperatures.

The "best" heat-resistant material is entirely dependent on the specific application. While tungsten excels in vacuum environments due to its record-high melting point for a metal, it fails catastrophically in open air at high temperatures and is often outperformed by advanced ceramics or specialized superalloys in real-world conditions.

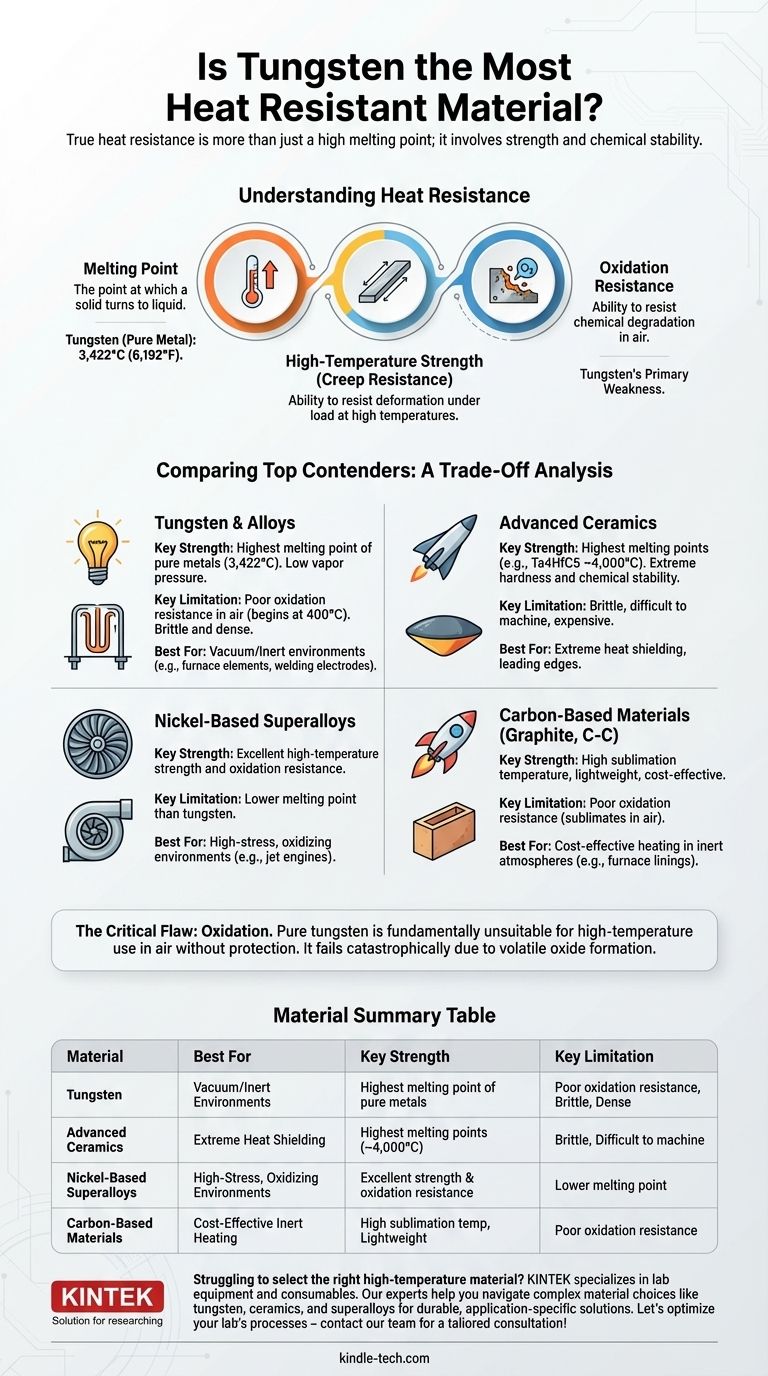

What "Heat Resistant" Truly Means

The term "heat resistant" is not a single property but a combination of factors. Understanding these distinctions is critical for selecting the right material for a high-temperature application.

Melting Point: The Simplest Metric

The most common measure of heat resistance is a material's melting point. In this category, tungsten is the champion among all pure metals, with a melting point of 3,422°C (6,192°F).

However, other materials have even higher melting or sublimation points. Carbon, for instance, sublimates (turns directly from a solid to a gas) at around 3,642°C. Even more impressively, certain ceramic compounds like Tantalum Hafnium Carbide (Ta4HfC5) have been shown to have melting points approaching 4,000°C (7,232°F).

High-Temperature Strength (Creep Resistance)

A material's ability to resist deformation under load at high temperatures is known as creep resistance. A material can be well below its melting point but still stretch, deform, and ultimately fail under mechanical stress.

While tungsten has good high-temperature strength, this is the domain where nickel-based superalloys often excel. They are engineered to maintain exceptional structural integrity at temperatures where many other metals would weaken, making them essential for high-stress parts like jet engine turbine blades.

Oxidation Resistance

This is arguably the most important factor in many real-world applications and is tungsten's primary weakness. In the presence of oxygen (i.e., in open air), tungsten begins to oxidize rapidly at temperatures as low as 400°C.

This process forms a volatile oxide layer that evaporates, quickly eroding the material. In contrast, materials like stainless steel and nickel superalloys form a stable, protective oxide layer that shields them from further degradation.

Comparing the Top Contenders

No single material wins in all categories. The ideal choice is always a trade-off based on the operating environment.

Tungsten and its Alloys

Tungsten is the go-to choice for applications that combine extreme heat with a vacuum or inert gas environment. Its high melting point and low vapor pressure make it perfect for incandescent bulb filaments, vacuum furnace heating elements, and TIG welding electrodes.

Carbon-Based Materials (Graphite, C-C)

Like tungsten, graphite has a very high sublimation temperature and is used extensively in high-heat, non-oxidizing environments. It is much lighter and less expensive than tungsten, making it ideal for furnace linings, rocket nozzles, and brake discs. Its primary limitation is also a lack of oxidation resistance.

Advanced Ceramics

Materials like Hafnium Carbide and Tantalum Hafnium Carbide are the undisputed champions of melting point. Their extreme hardness and chemical stability make them candidates for leading edges on hypersonic vehicles or advanced thermal shielding. However, they are typically brittle and very difficult to machine, limiting their widespread use.

Nickel-Based Superalloys

These are the workhorses for applications that require both high strength and oxidation resistance at high temperatures. They are not chosen for their melting point, which is lower than tungsten's, but for their ability to perform reliably under extreme mechanical and chemical stress in an oxygen-rich environment.

Understanding the Trade-offs: The Case of Tungsten

Choosing a material requires balancing its strengths and weaknesses for the specific job.

The Critical Flaw: Oxidation

To be clear: pure tungsten is fundamentally unsuitable for high-temperature use in air. It must be used in a vacuum, an inert atmosphere, or be protected with a specialized coating to prevent catastrophic failure.

Brittleness and Machinability

Tungsten is notoriously difficult to work with. It is very brittle at room temperature, which complicates machining and forming. This adds significant cost and complexity to manufacturing parts from tungsten.

Extreme Density

Tungsten is one of the densest elements, comparable to gold. This makes it an extremely poor choice for any application where weight is a concern, such as in the aerospace industry.

Making the Right Choice for Your Application

Selecting the correct material requires defining your primary challenge.

- If your primary focus is the highest possible melting point in a vacuum: Tungsten is an excellent metal choice, but advanced ceramics like Tantalum Hafnium Carbide hold the absolute record.

- If your primary focus is structural strength in an oxidizing environment (like a jet engine): Nickel-based superalloys are the industry standard and will dramatically outperform tungsten.

- If your primary focus is cost-effective heat resistance in an inert atmosphere: Graphite is often a superior and more practical choice than tungsten.

- If your primary focus is a very specific function like an electrical filament or welding electrode: Tungsten's unique combination of properties makes it the ideal, proven solution.

Ultimately, you must choose the material whose properties are precisely aligned with the mechanical, chemical, and thermal demands of its environment.

Summary Table:

| Material | Best For | Key Strength | Key Limitation |

|---|---|---|---|

| Tungsten | Vacuum/inert environments (e.g., furnace elements) | Highest melting point of pure metals (3,422°C) | Poor oxidation resistance in air; brittle and dense |

| Advanced Ceramics | Extreme heat shielding (e.g., hypersonic vehicles) | Highest melting points (e.g., Ta4HfC5 ~4,000°C) | Brittle; difficult to machine |

| Nickel-Based Superalloys | High-stress, oxidizing environments (e.g., jet engines) | Excellent strength and oxidation resistance at high temperatures | Lower melting point than tungsten |

| Carbon-Based Materials | Cost-effective heating in inert atmospheres (e.g., furnace linings) | High sublimation temperature; lightweight | Poor oxidation resistance |

Struggling to select the right high-temperature material for your lab equipment? At KINTEK, we specialize in lab equipment and consumables, helping you navigate complex material choices like tungsten, ceramics, and superalloys for furnaces, reactors, and more. Our experts ensure you get durable, application-specific solutions that withstand extreme conditions while optimizing performance and cost. Let’s optimize your lab’s high-temperature processes—contact our team today for a tailored consultation!

Visual Guide

Related Products

- High Purity Gold Platinum Copper Iron Metal Sheets

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- How thick is gold sputtering? Achieve Precise Coatings from Ångstroms to Microns

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- Where is soldering commonly used? From Everyday Electronics to Industrial Applications

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat