At their core, modern dental press furnaces are defined by the integration of intelligent software with precise mechanical systems. They combine features like intuitive touchscreen controls, a library of pre-set programs for various materials, and advanced temperature controllers to automate and perfect the creation of ceramic restorations.

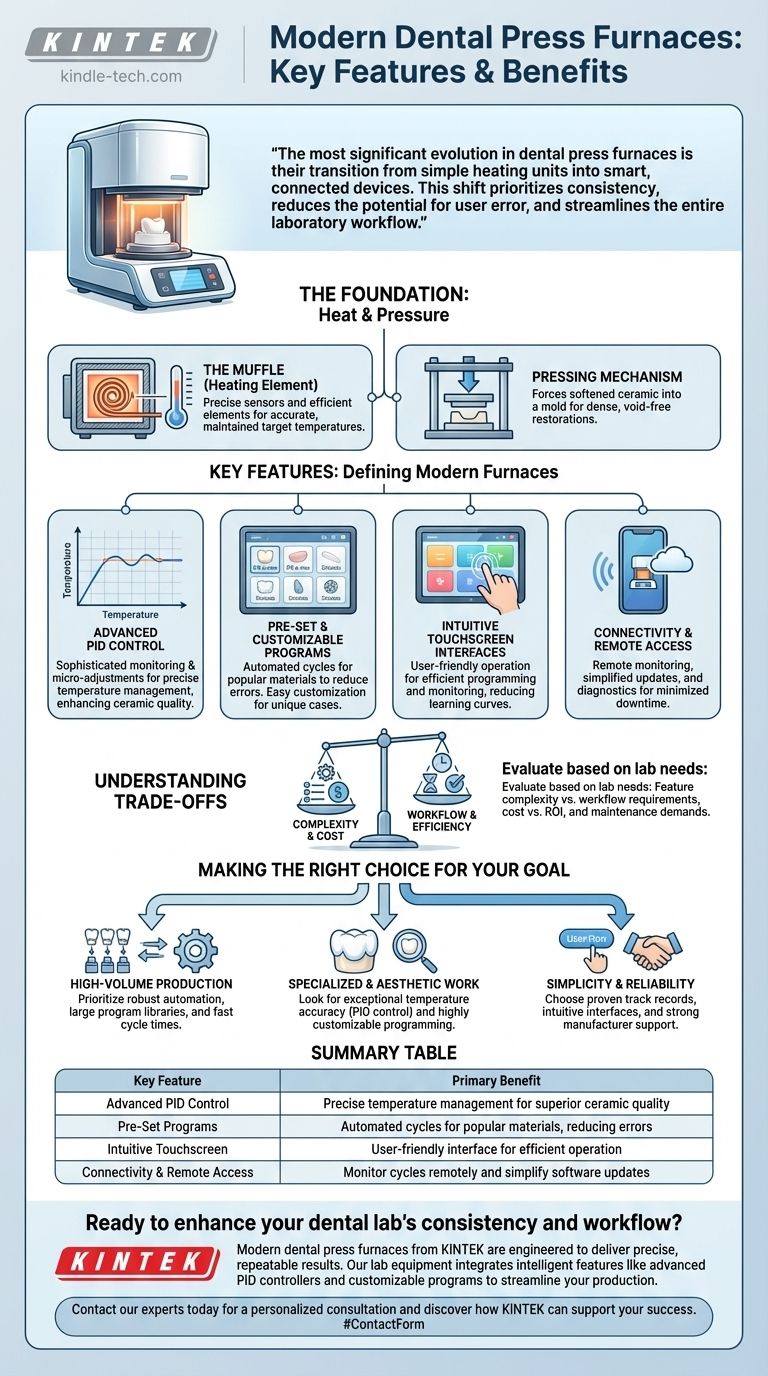

The most significant evolution in dental press furnaces is their transition from simple heating units into smart, connected devices. This shift prioritizes consistency, reduces the potential for user error, and streamlines the entire laboratory workflow.

The Foundation: Heat and Pressure

Before exploring modern features, it's essential to understand the furnace's primary role. It uses a combination of high temperature and controlled pressure to transform ceramic materials into hardened, final restorations like crowns, inlays, and onlays.

The Muffle and Heating Element

The muffle is the insulated inner chamber where the heating occurs. Modern furnaces use highly efficient and durable heating elements coupled with precise sensors to achieve and maintain target temperatures accurately.

The Pressing Mechanism

Simultaneously, a mechanical or pneumatic system applies specific levels of pressure. This forces the softened glass-ceramic material into a mold, ensuring a dense, void-free restoration that perfectly matches the desired shape.

Key Features That Define Modern Furnaces

Today's advancements are less about raw heating power and more about the intelligence that controls the process. These features ensure every cycle is repeatable and optimized for the specific material being used.

Advanced PID Temperature Control

Nearly all modern furnaces use a PID (Proportional-Integral-Derivative) controller. This is a sophisticated system that constantly monitors the temperature and makes micro-adjustments to prevent overshooting or undershooting the target. This level of precision is critical for the structural integrity and aesthetic quality of the ceramic.

Pre-Set and Customizable Programs

Manufacturers pre-load their furnaces with programs optimized for popular ceramic materials. This eliminates guesswork and ensures the technician uses the correct heating rates, hold times, and temperatures recommended by the material manufacturer. Most also allow for easy customization for unique cases.

Intuitive Touchscreen Interfaces

Clunky buttons and small digital readouts have been replaced by large, full-color touchscreen controls. This makes programming cycles, monitoring progress, and accessing settings far more intuitive and efficient, reducing the learning curve for technicians.

Connectivity and Remote Access

A growing number of furnaces feature internet connectivity. This allows for remote monitoring of cycles from a computer or phone, simplifies software updates from the manufacturer, and can assist with remote diagnostics and support, minimizing downtime.

Understanding the Trade-offs

While advanced features offer significant benefits, it's important to evaluate them objectively based on your lab's specific needs.

Feature Complexity vs. Workflow

A furnace with hundreds of programmable slots and advanced connectivity is ideal for a high-volume lab using many different materials. However, a smaller lab specializing in one or two materials may find a simpler, more streamlined interface to be more efficient.

The Cost of Advanced Technology

Features like Wi-Fi connectivity, large touchscreens, and extensive pre-set libraries increase the unit's cost. It is crucial to determine if these features will provide a tangible return on investment through increased efficiency or improved quality in your specific setting.

Maintenance and Calibration Demands

The precision of these devices is their greatest asset, but it relies on proper care. Highly accurate temperature and pressure systems require regular calibration to maintain their performance. This ongoing maintenance is a critical factor in the long-term reliability of the furnace.

Making the Right Choice for Your Goal

Selecting a furnace is about matching its capabilities to your laboratory's primary objectives.

- If your primary focus is high-volume production: Prioritize furnaces with robust automation, a large library of pre-set programs, and fast cycle times to maximize throughput.

- If your primary focus is specialized or aesthetic work: Look for furnaces with exceptional temperature accuracy (PID control) and highly customizable programming for full control over the firing process.

- If your primary focus is simplicity and reliability: Choose a furnace with a proven track record, an intuitive user interface, and strong manufacturer support, even if it lacks the latest connectivity features.

Ultimately, the right dental press furnace is an investment that enhances the consistency of your work and the efficiency of your operations.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Advanced PID Control | Precise temperature management for superior ceramic quality |

| Pre-Set Programs | Automated cycles for popular materials, reducing errors |

| Intuitive Touchscreen | User-friendly interface for efficient operation |

| Connectivity & Remote Access | Monitor cycles remotely and simplify software updates |

Ready to enhance your dental lab's consistency and workflow?

Modern dental press furnaces from KINTEK are engineered to deliver precise, repeatable results for crowns, inlays, and onlays. Our lab equipment integrates intelligent features like advanced PID controllers and customizable programs to streamline your production and improve restoration quality.

Let us help you find the perfect furnace for your lab's needs. Contact our experts today for a personalized consultation and discover how KINTEK can support your success.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges