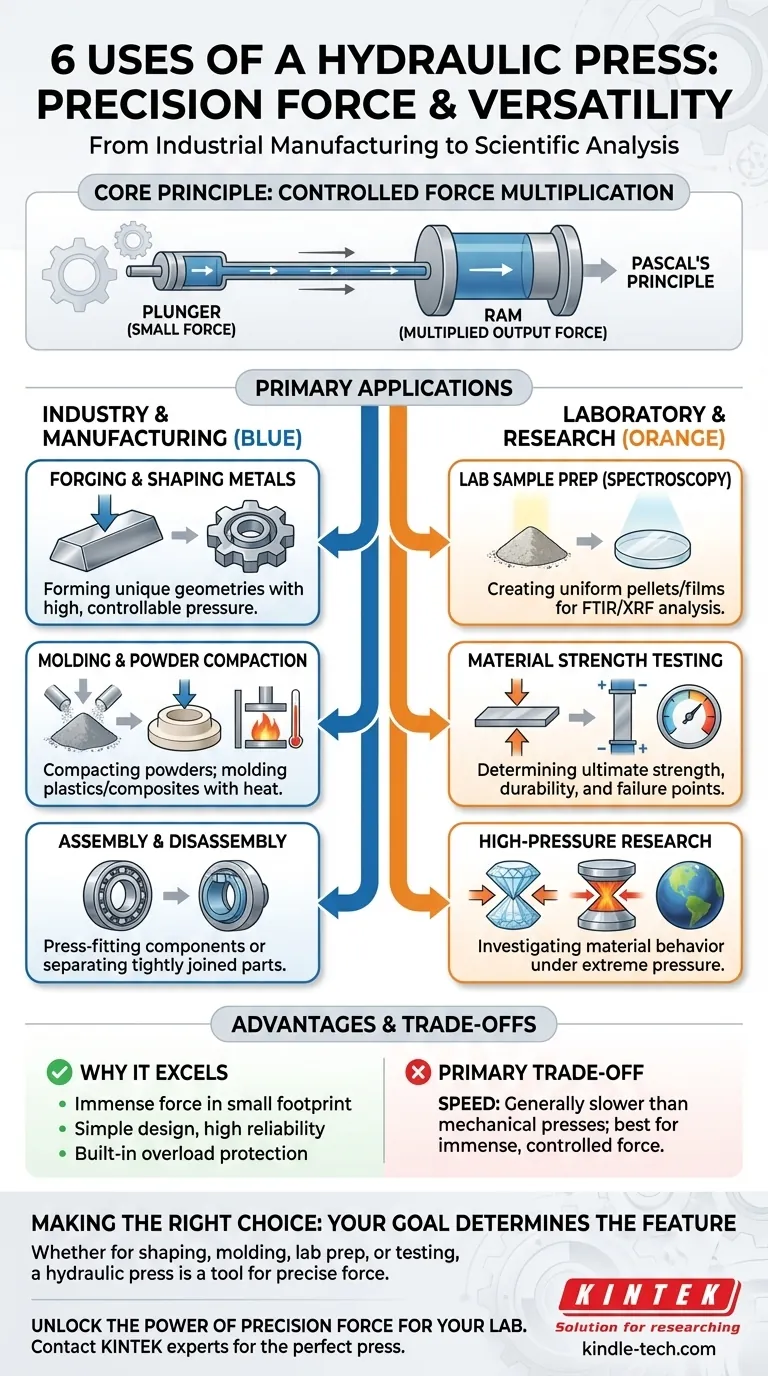

At its core, a hydraulic press is a tool of force multiplication. Its most common uses range from industrial manufacturing to detailed scientific analysis. The six primary applications include: forging and shaping metals, preparing laboratory samples for spectroscopy, testing material strength, compacting powders, molding various materials, and conducting high-pressure scientific research.

The true value of a hydraulic press isn't just its immense power, but its precise control. Understanding this dual capability is key to seeing why it's an essential tool in workshops and laboratories alike, used for both creating and analyzing.

The Core Principle: Controlled Force Multiplication

A hydraulic press operates on a simple but powerful law of physics known as Pascal's Principle. This principle states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

How It Works: The Ram and Plunger

A hydraulic press uses two connected cylinders of different sizes, filled with a fluid like oil. A small force applied to the smaller cylinder (the plunger) generates pressure in the fluid. This same pressure then acts on the much larger cylinder (the ram), creating a massively multiplied output force.

The Importance of Precision

Modern hydraulic systems give an operator exceptional control over the speed and pressure of the ram. This is not a simple crushing machine; it is a precision instrument that can apply a specific amount of force at a specific rate, enabling the creation of complex and delicate products.

Key Applications in Industry and Manufacturing

In an industrial setting, the hydraulic press is a workhorse, valued for its power, reliability, and versatility.

Forging and Shaping Metals

One of the most common uses is forging, where a metal ingot or billet is pressed into a desired shape. The high, controllable pressure allows operators to form unique and complex geometries that might be impossible with other methods.

Molding and Powder Compaction

Hydraulic presses are used to compact powders into solid forms, from pharmaceuticals to ceramic parts. Hot presses add temperature control to the process, allowing for the molding of plastics, composites, and other materials that need both heat and pressure to set.

Assembly and Disassembly

The immense force is also used for press-fitting components, such as inserting bearings into a housing or gears onto a shaft. The same force can be used in reverse to disassemble parts that are tightly joined.

Critical Roles in the Laboratory

In a scientific or quality control lab, the hydraulic press is essential for preparing materials for analysis and testing their physical properties.

Sample Preparation for Spectroscopy

To get an accurate reading from analytical instruments like FTIR or XRF spectrometers, the sample must be uniform. A lab press is used to compress a powdered sample into a perfectly flat, homogenous pellet or thin film, ensuring the analytical beam gets a consistent and representative reading.

Material Strength and Durability Testing

Engineers and material scientists use hydraulic presses to test the limits of materials. By applying a measured compressive or tensile force, they can determine a material's ultimate strength, durability, and failure points.

High-Pressure Research

Scientists use hydraulic presses to investigate how different substances behave under extreme pressure. This is critical for fields like geology (simulating conditions deep within the Earth) and materials science (creating new synthetic materials).

Understanding the Advantages and Trade-offs

Choosing a hydraulic press involves understanding its distinct benefits and limitations compared to other machine types, like mechanical presses.

Why a Hydraulic Press Excels

The design offers several key advantages. It can generate immense force in a relatively small footprint and has a simple design with fewer moving parts, leading to higher reliability and a longer tool lifespan. Crucially, they have built-in overload protection; the system simply bypasses fluid when it hits its maximum pressure limit, preventing damage to the machine.

The Primary Trade-off: Speed

The main limitation of a hydraulic press is its cycle speed. It is generally slower than a mechanical press, which uses a flywheel and crank for very rapid stamping operations. Therefore, it is better suited for jobs that require immense, controlled force rather than high-speed repetition.

Making the Right Choice for Your Goal

Your intended use case will determine which feature of the hydraulic press is most valuable to you.

- If your primary focus is industrial manufacturing: You will leverage the press for its ability to shape, mold, and form materials with high, controllable force.

- If your primary focus is scientific research or quality control: The press is an essential tool for preparing uniform samples for analysis and for testing the physical limits of materials.

- If your primary focus is efficiency and safety: The hydraulic press offers a design with built-in overload protection, high reliability, and a smaller footprint compared to many mechanical alternatives.

Ultimately, understanding that a hydraulic press is a tool for precise force application unlocks its potential for nearly any task requiring immense pressure.

Summary Table:

| Application | Primary Use Case |

|---|---|

| Forging & Shaping | Forming metals into complex shapes |

| Lab Sample Prep | Creating uniform pellets for spectroscopy (FTIR/XRF) |

| Material Testing | Determining strength, durability, and failure points |

| Powder Compaction | Compressing powders into solid forms (e.g., ceramics) |

| Molding | Shaping plastics/composites with heat and pressure |

| High-Pressure Research | Simulating extreme conditions for material science |

Unlock the Power of Precision Force for Your Lab

Whether you are preparing flawless samples for spectroscopy or testing material strength, the right hydraulic press is critical for accuracy and reliability. KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for the precise demands of research and quality control.

Let us help you enhance your laboratory's capabilities. Contact our experts today to find the perfect press for your specific application and ensure your results are consistently accurate.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury