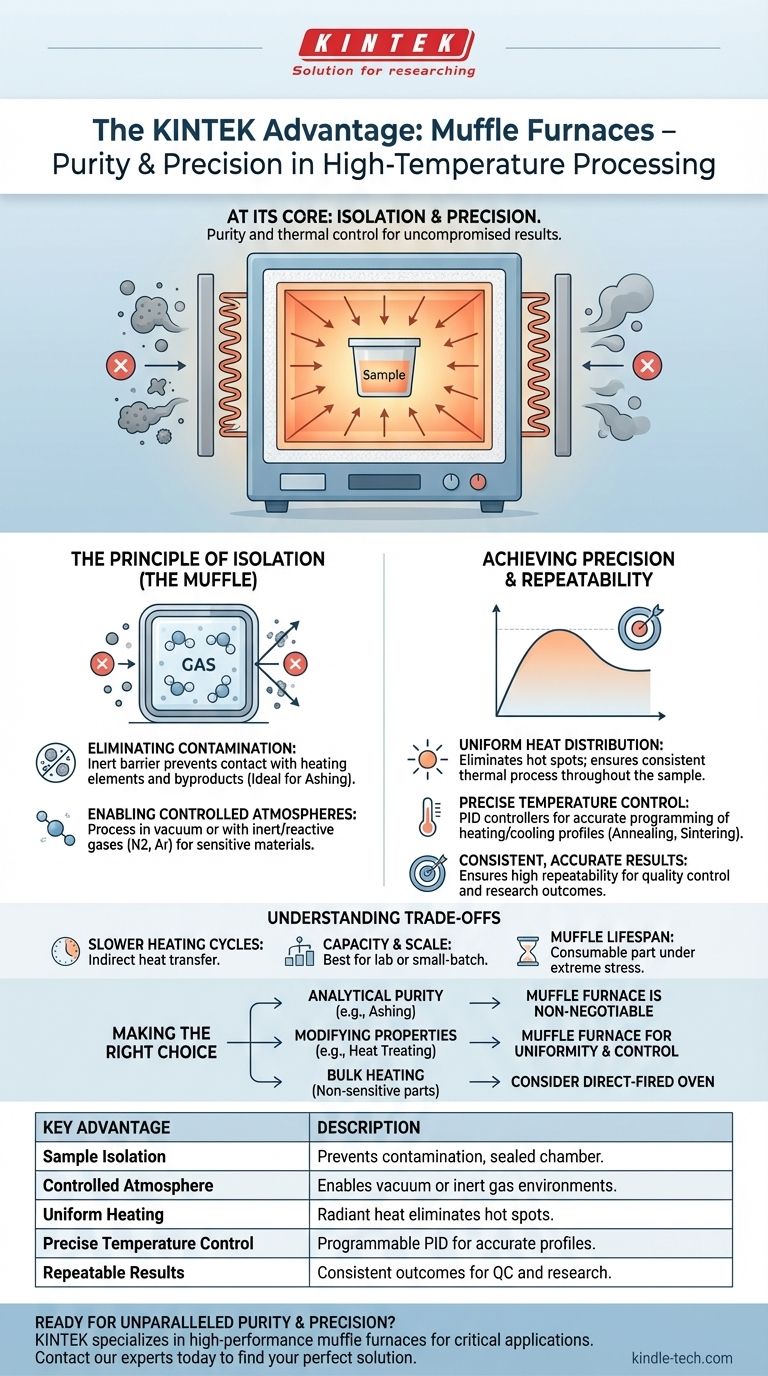

At its core, a muffle furnace provides two distinct and critical advantages. It delivers exceptionally uniform, high-temperature heat while completely isolating the material being processed from the heating elements and any potential contaminants. This combination of process purity and thermal precision makes it an indispensable tool in both scientific laboratories and specialized industrial settings.

The true value of a muffle furnace lies not just in its ability to reach high temperatures, but in its capacity to create a pristine and highly controlled heating environment. This ensures that the results of any process—be it chemical analysis or material treatment—are accurate, repeatable, and uncompromised.

The Principle of Isolation: Why the "Muffle" Matters

The defining feature of this furnace is the "muffle"—a sealed inner chamber that separates your sample from the outside world. This fundamental design choice is the source of its primary benefits.

Eliminating Contamination

In many high-temperature processes, direct exposure to fuel byproducts or even the heating elements themselves can alter a sample's chemical composition. The muffle acts as an inert barrier, preventing this contamination.

This is especially critical for analytical procedures like ashing, where the goal is to measure the inorganic residue of a sample. Any external contaminants would render the results invalid.

Enabling Controlled Atmospheres

Because the sample chamber is sealed, you can control the gaseous environment within it. This allows for processing in a vacuum or introducing specific inert or reactive gases like nitrogen or argon.

This capability is essential for preventing oxidation in sensitive metals or facilitating specific chemical reactions that are only possible under a controlled atmosphere.

Achieving Precision and Repeatability

Isolation creates a pure environment, but the furnace's design also ensures that the heat applied within that environment is perfectly managed.

Uniform Heat Distribution

Muffle furnaces are engineered to radiate heat evenly onto the sample from multiple sides. This design eliminates hot spots and temperature gradients common in direct-fired systems.

Uniform heating ensures that the entire sample undergoes the exact same thermal process, which is crucial for achieving consistent material properties.

Precise Temperature Control

Modern muffle furnaces use sophisticated PID (Proportional-Integral-Derivative) controllers. These allow for precise programming of heating rates, holding times, and cooling profiles.

This level of control is necessary for complex heat-treating processes like annealing, tempering, and sintering, where the material's final characteristics depend on a specific thermal journey.

Consistent, Accurate Results

The combination of a pure environment, uniform heating, and precise control leads to exceptional repeatability. Whether for quality control testing or scientific research, a muffle furnace ensures that each process run will produce the same outcome.

Understanding the Trade-offs

While powerful, a muffle furnace is not the universal solution for all heating tasks. Understanding its limitations is key to using it effectively.

Slower Heating Cycles

Because heat must transfer indirectly—from the elements, through the muffle wall, and to the sample—heating cycles can be slower compared to direct-fired furnaces. This is a trade-off for achieving thermal uniformity and purity.

Capacity and Scale

Muffle furnaces are typically designed for laboratory or small-batch industrial applications. They are not generally suited for heating very large components or for high-throughput manufacturing where speed is more important than precision.

Muffle Material and Lifespan

The muffle chamber itself is exposed to extreme thermal stress and can degrade over time, especially when used at maximum temperatures or with reactive atmospheres. It should be considered a long-term consumable part that may require eventual replacement.

Making the Right Choice for Your Application

Selecting the right heating tool depends entirely on your primary objective.

- If your primary focus is analytical purity (e.g., ashing, trace element analysis): The muffle furnace is non-negotiable, as its sample isolation prevents contamination that would invalidate your results.

- If your primary focus is modifying material properties (e.g., heat treating, annealing): The muffle furnace's uniform heating and precise temperature control are its key advantages for achieving specific, repeatable metallurgical or ceramic characteristics.

- If your primary focus is simply bulk heating of non-sensitive parts: A less complex and potentially faster direct-fired oven or furnace might be a more practical and cost-effective solution.

Ultimately, a muffle furnace is the definitive tool when process integrity and repeatable precision cannot be compromised.

Summary Table:

| Key Advantage | Description |

|---|---|

| Sample Isolation | Sealed muffle chamber prevents contamination from heating elements and fuel byproducts. |

| Controlled Atmosphere | Enables processing in a vacuum or with inert/reactive gases like nitrogen or argon. |

| Uniform Heating | Radiates heat evenly to eliminate hot spots and ensure consistent sample treatment. |

| Precise Temperature Control | Sophisticated PID controllers allow for accurate programming of heating and cooling profiles. |

| Repeatable Results | The combination of purity and precision ensures consistent outcomes for quality control and research. |

Ready to achieve unparalleled purity and precision in your lab?

KINTEK specializes in high-performance laboratory equipment, including muffle furnaces designed for critical applications like ashing, heat treatment, and material sintering. Our solutions provide the contamination-free environment and precise temperature control your work demands.

Contact our experts today to find the perfect muffle furnace for your specific laboratory needs and ensure your processes are accurate, repeatable, and uncompromised.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the inside material of a muffle furnace? Choose the Right Lining for Your Application

- What is the heat transfer of a muffle furnace? Understanding Indirect Heating for Purity

- How do you prepare samples for IR? A Guide to Solid, Liquid, and Gas Sample Prep

- What is the tolerance of a muffle furnace? A Guide to Temperature Accuracy & Uniformity

- What is the importance of melting process? Master the Foundation of Metal Production