From a technical standpoint, the primary advantages of a power press are its exceptional speed, precision, and cost-effectiveness for high-volume production. Unlike hydraulic presses that rely on fluid pressure, a mechanical power press uses a flywheel to store and rapidly release energy, enabling a very high number of strokes per minute with outstanding consistency.

A power press is the definitive solution for mass production where speed and repeatability are paramount. Its advantages are rooted in its mechanical design, but this specialization comes at the cost of the flexibility found in other press types.

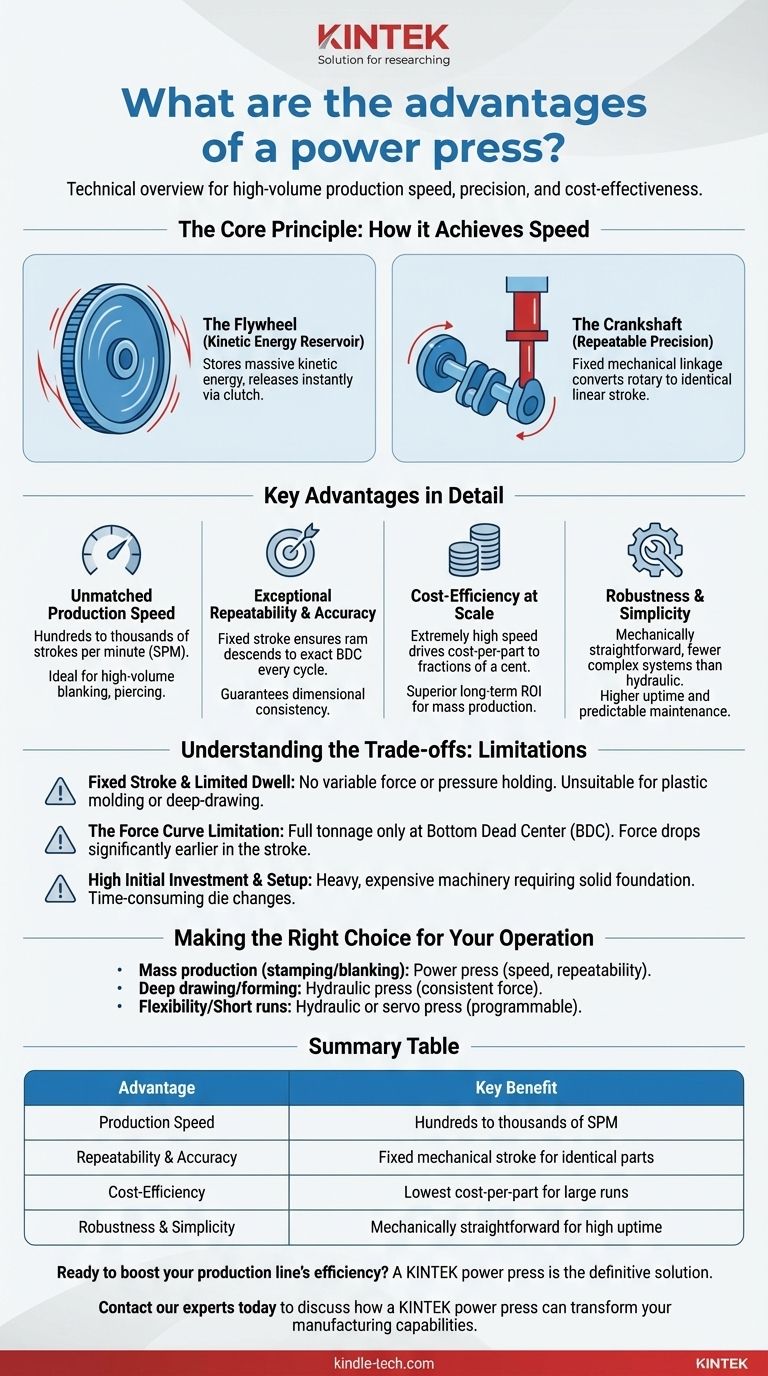

The Core Principle: How a Power Press Achieves its Speed

To understand the advantages of a power press, you must first understand its core mechanical principle. It's not about generating raw force, but about storing and delivering it with incredible speed.

The Flywheel: A Reservoir of Kinetic Energy

A large electric motor continuously spins a heavy flywheel, which stores a massive amount of kinetic energy. Think of it like a pitcher winding up for a fastball.

When the operator engages the clutch, this stored energy is transferred almost instantaneously through the crankshaft to the ram. This allows for a powerful stroke without needing an impractically large motor for each cycle.

The Crankshaft: Guaranteeing Repeatable Precision

The energy from the flywheel drives a crankshaft, which converts rotary motion into the linear, vertical motion of the ram.

Because this is a fixed mechanical linkage, the length and path of the stroke are identical every single time. This mechanical certainty is the source of the power press's renowned precision and repeatability.

Key Advantages in Detail

The mechanical nature of a power press directly translates into several key operational benefits, particularly in the context of large-scale manufacturing.

Unmatched Production Speed

The defining advantage is speed. A power press can achieve hundreds, and in some cases thousands, of strokes per minute (SPM).

This high cycle rate makes it the undisputed choice for operations like blanking, piercing, and shallow forming where millions of identical parts are needed quickly.

Exceptional Repeatability and Accuracy

The fixed stroke of the crankshaft ensures that the ram descends to the exact same point—Bottom Dead Center (BDC)—with every cycle.

This guarantees dimensional consistency from the first part to the millionth, which is critical for quality control and the production of interchangeable components.

Cost-Efficiency at Scale

While the initial investment in a power press and its tooling is significant, the extremely high production speed drives the cost-per-part down to fractions of a cent.

For any high-volume stamping operation, the long-term return on investment is superior to almost any other fabrication method.

Robustness and Simplicity

Compared to the complex valving, seals, and fluid management of a hydraulic system, a well-maintained mechanical press is a robust and mechanically straightforward machine.

This often translates to higher uptime and more predictable maintenance schedules over the life of the equipment.

Understanding the Trade-offs: When a Power Press is Not the Right Choice

True expertise lies in knowing a tool's limitations. A power press is highly specialized, and its advantages create inherent disadvantages in other areas.

Fixed Stroke and Limited Dwell Time

The stroke length is mechanically fixed and cannot be easily changed. Furthermore, you cannot "dwell" or hold pressure at the bottom of the stroke, as the ram immediately begins its return path.

This makes mechanical presses unsuitable for applications requiring variable force or pressure to be held over time, such as plastic molding or some deep-drawing operations.

The Force Curve Limitation

A mechanical press only delivers its full rated tonnage at the very bottom of the stroke (BDC). The available force is significantly lower at the beginning or middle of the stroke.

If your operation requires consistent force throughout the entire forming process, a hydraulic press is a technically superior choice as it provides full tonnage at any point in its stroke.

High Initial Investment and Setup

Power presses are heavy, expensive machines that require significant capital and a robust foundation.

Furthermore, changing the die sets for a new production run can be a time-consuming and labor-intensive process, making them inefficient for short runs or prototyping.

Making the Right Choice for Your Operation

Choosing the correct press is about matching the machine's capabilities to your specific manufacturing goal.

- If your primary focus is mass production of stamped or blanked parts: A mechanical power press is the most efficient and cost-effective solution due to its speed and repeatability.

- If your primary focus is deep drawing or forming: A hydraulic press is likely a better choice, as it delivers consistent force throughout its entire stroke.

- If your primary focus is flexibility for short runs or prototyping: You should evaluate a hydraulic press for its variable stroke and force, or a modern servo press for its full programmability.

Ultimately, understanding these fundamental trade-offs empowers you to select the right tool for the job.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Production Speed | Hundreds to thousands of strokes per minute (SPM) |

| Repeatability & Accuracy | Fixed mechanical stroke ensures identical parts |

| Cost-Efficiency | Lowest cost-per-part for large production runs |

| Robustness & Simplicity | Mechanically straightforward for high uptime |

Ready to boost your production line's efficiency?

A power press from KINTEK is the definitive solution for high-volume stamping, blanking, and piercing. Our expertise in lab and industrial equipment ensures you get a robust, high-performance machine tailored to your mass production needs, driving down your cost-per-part and guaranteeing exceptional quality.

Contact our experts today to discuss how a KINTEK power press can transform your manufacturing capabilities.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Double Plate Heating Press Mold for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance