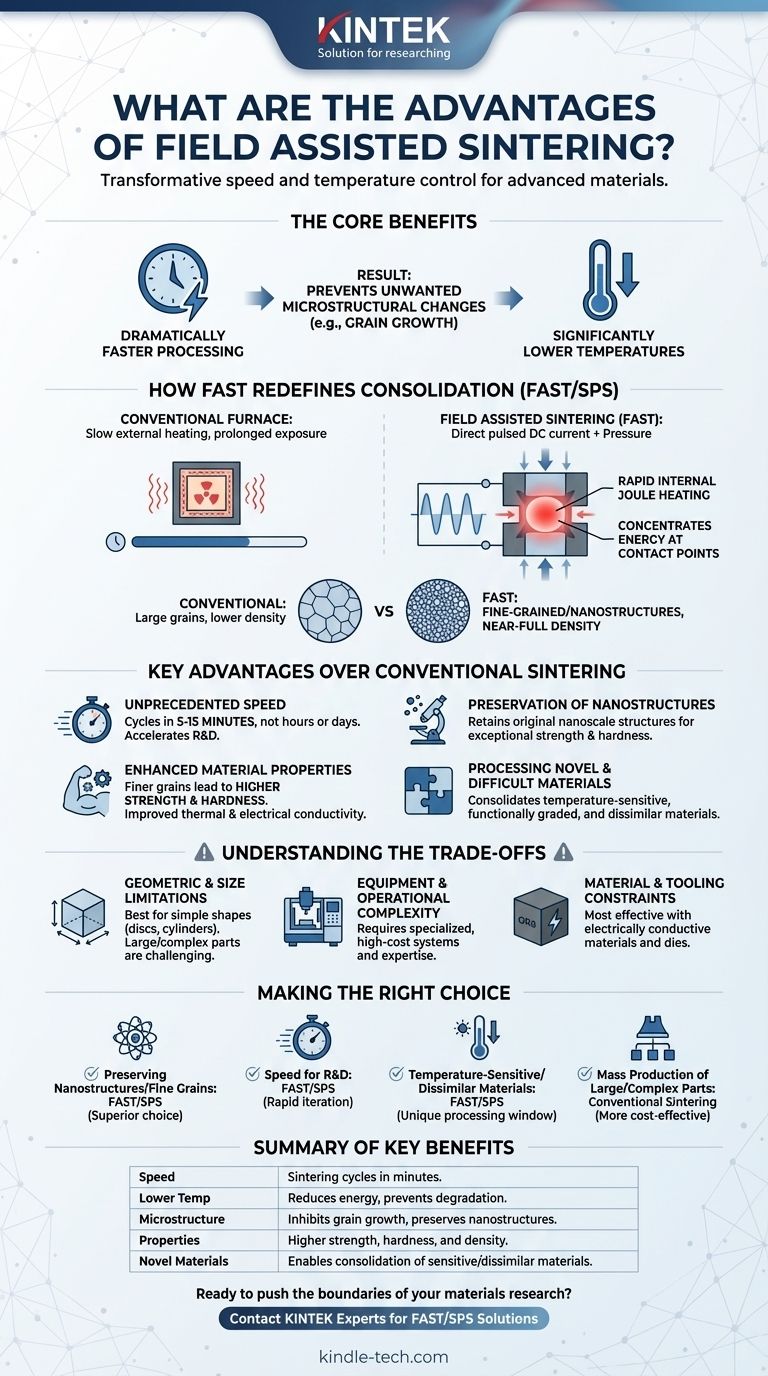

In essence, field assisted sintering offers two transformative advantages over conventional methods: dramatically faster processing times and significantly lower sintering temperatures. These core benefits allow for the creation of advanced materials with superior properties by preventing the unwanted microstructural changes, such as grain growth, that occur during prolonged, high-temperature furnace treatments.

The fundamental advantage of field assisted sintering is its mechanism. By passing a pulsed electric current directly through the powder compact, it generates intense, localized heat precisely where it's needed, enabling consolidation in minutes rather than hours and preserving delicate nanoscale and fine-grained structures that would be destroyed in a traditional furnace.

How Field Assisted Sintering Redefines Consolidation

To understand the advantages, it's crucial to understand how Field Assisted Sintering Technology (FAST)—often called Spark Plasma Sintering (SPS)—differs from conventional furnace heating.

The Role of Direct Current and Joule Heating

Instead of relying on slow, external radiation and convection in a furnace, FAST applies both pressure and a high-amperage, low-voltage pulsed DC current.

This current passes directly through the conductive die and, in many cases, the powder material itself. This generates rapid, internal Joule heating, concentrating thermal energy at the contact points between powder particles.

Lower Temperatures, Superior Microstructures

This localized heating is incredibly efficient, allowing the bulk material to reach consolidation temperature much faster and often at a lower overall setpoint than in a conventional furnace.

Because the material spends significantly less time at high temperatures, grain growth is drastically inhibited. This is the single most important metallurgical benefit of the process.

Key Advantages Over Conventional Sintering

The unique mechanism of FAST/SPS translates into tangible benefits for materials development and production.

Unprecedented Speed

Sintering cycles that take many hours or even days in a conventional furnace can be completed in as little as 5 to 15 minutes using FAST. This accelerates research, development, and small-scale production cycles immensely.

Preservation of Nanostructures

For advanced materials, maintaining a nano-scale grain structure is critical for achieving exceptional strength, hardness, and other unique properties. FAST is one of the few techniques capable of fully densifying nanopowders while retaining their original nanostructure.

Enhanced Material Properties

By preventing grain growth and achieving near-full density, FAST produces materials with improved mechanical and functional properties. Fine-grained materials are typically stronger and harder (per the Hall-Petch relationship), and high density improves thermal and electrical conductivity.

Processing Novel and Difficult Materials

The combination of low temperature and short duration enables the consolidation of materials that are impossible to process conventionally. This includes temperature-sensitive materials, functionally graded materials, and dissimilar material combinations (e.g., metal-ceramic) that would otherwise react or decompose.

Understanding the Trade-offs

No technology is without limitations. Objectivity requires acknowledging the challenges associated with field assisted sintering.

Geometric and Size Limitations

The FAST process is typically limited to simple geometries like discs, squares, and cylinders that can be contained within a graphite die. Producing large or highly complex parts is often impractical or economically unfeasible compared to other methods.

Equipment and Operational Complexity

FAST/SPS systems are specialized, high-cost machines requiring significant capital investment. They demand more operator expertise and process control than a standard industrial furnace.

Material and Tooling Constraints

The process is most effective with electrically conductive materials and dies (typically graphite). While insulating materials can be sintered, it requires specialized tooling and process setups that can negate some of the speed and efficiency advantages.

Making the Right Choice for Your Goal

Selecting the right sintering technique depends entirely on your material, desired properties, and production goals.

- If your primary focus is preserving nanostructures or fine grains: FAST/SPS is the superior choice, as it minimizes the thermal exposure that drives grain growth.

- If your primary focus is speed for research and development: The rapid cycles of FAST allow for faster iteration and material discovery than any conventional method.

- If your primary focus is consolidating temperature-sensitive or dissimilar materials: FAST provides a unique processing window to create novel composites and alloys that cannot be made otherwise.

- If your primary focus is mass production of large or geometrically complex parts: Conventional sintering or methods like metal injection molding are almost always more cost-effective and scalable.

Ultimately, field assisted sintering is a powerful tool for pushing the boundaries of material performance and creating the next generation of advanced materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed | Sintering cycles in minutes, not hours or days. |

| Lower Temperature | Reduces energy use and prevents material degradation. |

| Microstructure Control | Inhibits grain growth to preserve nanostructures. |

| Material Properties | Achieves higher strength, hardness, and density. |

| Novel Materials | Enables consolidation of temperature-sensitive or dissimilar materials. |

Ready to push the boundaries of your materials research?

Field Assisted Sintering Technology (FAST/SPS) from KINTEK enables you to create advanced materials with superior properties, faster than ever before. Whether you're working with nanostructures, novel composites, or temperature-sensitive materials, our expertise and lab equipment solutions can help you achieve your goals.

Contact our experts today to discuss how FAST/SPS can accelerate your development cycle and enhance your material performance.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Three-dimensional electromagnetic sieving instrument

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- Why is graphite foil used in Spark Plasma Sintering (SPS)? Protect Your Molds and Enhance Sample Homogeneity

- Why is high-precision temperature control at 630°C necessary for Al-Sc vacuum hot pressing? Optimize Alloy Stability

- How does pressure in vacuum hot-pressing affect Cu-2Ni-7Sn/45 steel? Achieve High-Strength Metallurgical Bonds

- By what mechanism does a vacuum hot press sintering (HPS) furnace achieve the consolidation of NiAl-Al2O3 powders?

- Why is a vacuum hot press furnace preferred for bulk nano-tungsten? Preserving Microstructure via Low-Heat Pressing

- How does a Hot Isostatic Press (HIP) improve W-Cu densification? Achieve Near-Theoretical Density with High Pressure

- What advantages does a vacuum hot pressing sintering furnace offer over traditional sintering? Achieve Fine Grain Control

- What is the necessity of pre-pressing composite powders? Enhance Stability in Vacuum Hot-Pressing Sintering