The primary advantages of a handheld XRF analyzer are its exceptional portability for on-site analysis, the rapid speed at which it delivers results, and its non-destructive nature. This combination allows for immediate, in-field elemental analysis and material identification without damaging the sample being tested, fundamentally changing workflows that would otherwise require sending samples to a laboratory.

Handheld XRF brings the power of elemental analysis out of the laboratory and directly to your sample. While this delivers unparalleled speed and convenience for on-the-spot decision-making, it involves specific trade-offs in analytical precision and element range compared to its lab-based counterparts.

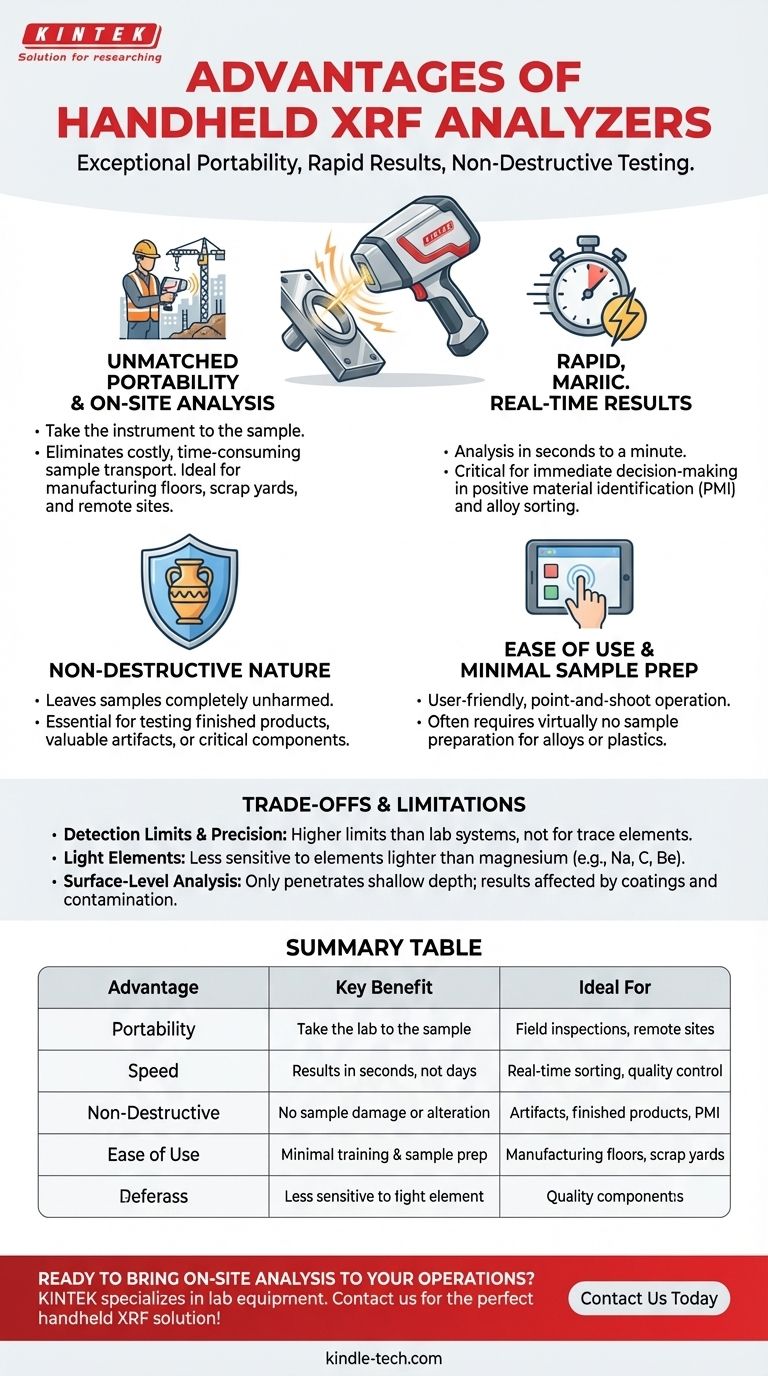

The Core Advantages Explained

Unmatched Portability and On-Site Analysis

The most significant advantage is the ability to take the instrument to the sample, not the other way around. This eliminates the costly and time-consuming process of sample collection, packaging, and shipping.

Handheld analyzers are designed for use on manufacturing floors, in scrap yards, at remote geological sites, or during building inspections. They provide answers where they are needed most.

Rapid, Real-Time Results

A typical analysis with a handheld XRF takes anywhere from a few seconds to a minute. Lab-based methods can take hours or even days to return results.

This immediacy is critical for applications like positive material identification (PMI) on a production line or sorting valuable alloys in a scrap yard, where quick decisions directly impact productivity and profitability.

Non-Destructive Nature

X-ray fluorescence is a non-destructive testing (NDT) technique. The analysis leaves the sample completely unharmed and unaltered.

This is essential when testing finished products, valuable historical or archaeological artifacts, or critical components that must be returned to service after verification.

Ease of Use and Minimal Sample Prep

Modern handheld XRF analyzers are designed with user-friendly interfaces, often resembling a simple point-and-shoot operation for routine tasks.

For many applications, especially analyzing metal alloys or plastics, virtually no sample preparation is required. This contrasts sharply with lab techniques that often require samples to be cut, ground, or digested in acid.

Understanding the Trade-offs and Limitations

Detection Limits and Precision

While powerful, handheld units generally have higher detection limits than high-power, laboratory-based XRF or Inductively Coupled Plasma (ICP) systems.

They are excellent for identifying major and minor elements but may not be suitable for measuring trace elements at parts-per-million (ppm) or parts-per-billion (ppb) levels with high precision.

Analysis of Light Elements

XRF technology is inherently less sensitive to very light elements (those with low atomic numbers, like magnesium, aluminum, silicon).

Analyzing elements lighter than magnesium, such as sodium, carbon, or beryllium, is typically not possible with handheld XRF. Performance for light alloys must be carefully evaluated for the specific application.

Surface-Level Analysis

Handheld XRF is fundamentally a surface analysis technique. The X-rays only penetrate a shallow depth into the material, from micrometers to millimeters, depending on the material's density.

This means that coatings, platings, or surface contamination (like rust or dirt) will affect the results. The reading may not represent the bulk composition of the material if the surface is not representative of the whole.

Is a Handheld XRF Right for Your Application?

To determine if this technology fits your needs, consider the primary goal of your analysis.

- If your primary focus is rapid sorting and material verification: Handheld XRF is an ideal tool, offering unmatched speed for alloy grade identification, scrap sorting, and quality control.

- If your primary focus is high-precision analysis of trace elements: You should consider laboratory methods like ICP-OES or ICP-MS, as they provide superior detection limits and accuracy for this work.

- If your primary focus is analyzing coatings or very light alloys: You must understand the limitations and may need a specialized model or an alternative technology like Laser-Induced Breakdown Spectroscopy (LIBS).

Understanding these capabilities and limitations allows you to leverage handheld XRF as a powerful tool for immediate, actionable data in the field.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Portability | Take the lab to the sample | Field inspections, remote sites |

| Speed | Results in seconds, not days | Real-time sorting, quality control |

| Non-Destructive | No sample damage or alteration | Artifacts, finished products, PMI |

| Ease of Use | Minimal training and sample prep | Manufacturing floors, scrap yards |

Ready to bring the power of on-site elemental analysis to your operations? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our handheld XRF analyzers deliver the speed and portability your team needs for immediate, actionable data in the field. Contact us today to find the perfect solution for your material identification and verification challenges!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency