At its core, the primary advantage of Low Pressure Chemical Vapor Deposition (LPCVD) is its ability to produce exceptionally uniform and high-quality thin films. By significantly reducing the operating pressure, this process minimizes unwanted gas-phase reactions, allowing the chemical precursors to coat complex, three-dimensional surfaces with remarkable consistency and purity.

The decision to use LPCVD is a strategic trade-off. You sacrifice deposition speed for a dramatic improvement in film uniformity, conformability, and purity, making it the preferred method for high-precision applications like semiconductor manufacturing.

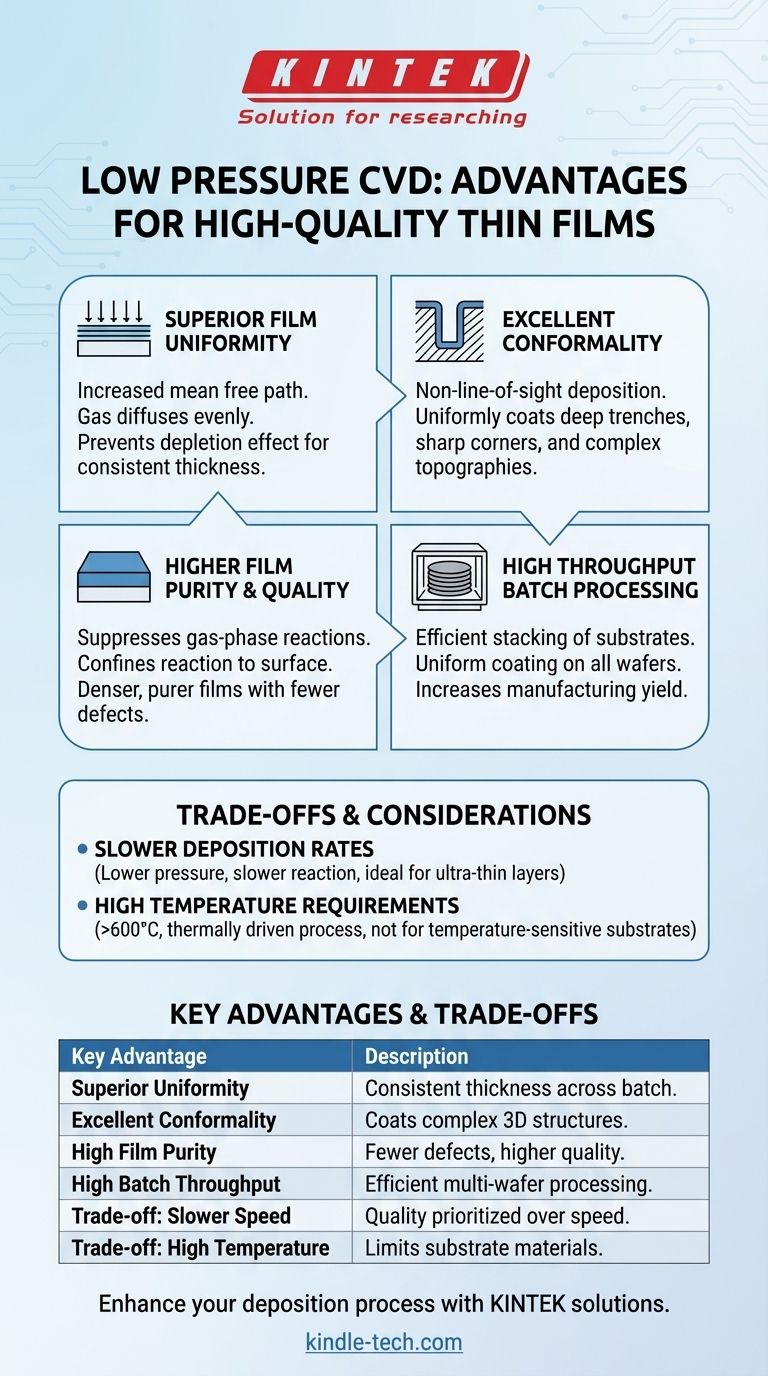

The Fundamental Advantages of Low-Pressure Operation

The defining characteristic of LPCVD is its sub-atmospheric operating environment. This single factor is the source of its most significant advantages over other deposition methods.

Superior Film Uniformity

Operating at low pressure increases the mean free path of gas molecules. This allows precursor gases to diffuse and spread out more evenly throughout the reaction chamber before they react on the substrate surface.

This prevents the "depletion effect," where gases are used up at the front of a substrate batch, ensuring that surfaces at the end of the line receive the same amount of material as those at the beginning.

Excellent Conformality

Conformality refers to a film's ability to coat a textured or non-flat surface with a uniform thickness. LPCVD excels at this.

Because the deposition is not "line-of-sight," the gas precursors can reach and react within deep trenches, sharp corners, and other complex topographies, creating a consistent layer everywhere. This is critical for building modern integrated circuits.

Higher Film Purity and Quality

Many unwanted side reactions can occur in the gas phase at atmospheric pressure, creating tiny particles that can fall onto the substrate and create defects.

By lowering the pressure, LPCVD suppresses these gas-phase reactions. The chemical reaction is instead confined to the hot substrate surface, resulting in a denser, purer, and higher-quality film with fewer impurities.

High Throughput for Batch Processing

The exceptional uniformity of LPCVD allows for a highly efficient processing arrangement. Substrates, such as silicon wafers, can be stacked vertically and close together in a furnace tube.

Even with tight spacing, the precursor gases can diffuse between the wafers to create uniform films on every single one. This enables large batch processing, dramatically increasing manufacturing yield and throughput.

Understanding the Trade-offs of LPCVD

No process is perfect. The advantages of LPCVD come with specific operational considerations that make it unsuitable for certain applications.

Slower Deposition Rates

The primary trade-off for high quality is speed. Lowering the pressure reduces the concentration of precursor molecules, which naturally slows down the rate of the chemical reaction and film deposition.

While this is acceptable for creating the ultra-thin layers needed in microelectronics, it can be inefficient for applications requiring very thick coatings.

High Temperature Requirements

LPCVD is a thermally driven process, relying on high heat (often 600°C or higher) to provide the energy needed for the chemical reactions to occur on the substrate surface.

This high temperature can be a significant limitation. It can damage or alter underlying layers on a partially built device and is incompatible with temperature-sensitive substrates like plastics.

Making the Right Choice for Your Application

The decision to use LPCVD depends entirely on your specific process priorities and material constraints.

- If your primary focus is film quality and uniformity: LPCVD is the superior choice, especially for coating complex 3D structures in semiconductor fabrication.

- If your primary focus is maximum deposition speed: You may need to consider other methods like Atmospheric Pressure CVD (APCVD) or plasma-enhanced techniques, but be prepared for a trade-off in film quality.

- If you are working with temperature-sensitive substrates: You must explore lower-temperature alternatives like Plasma-Enhanced CVD (PECVD), as the high heat of LPCVD will be unsuitable.

By understanding these core principles, you can confidently select the deposition technique that best aligns with your engineering goals.

Summary Table:

| Key Advantage | Description |

|---|---|

| Superior Uniformity | Minimizes gas depletion for consistent film thickness across a batch of wafers. |

| Excellent Conformality | Uniformly coats complex 3D structures, trenches, and sharp corners. |

| High Film Purity | Suppresses gas-phase reactions, resulting in fewer defects and impurities. |

| High Batch Throughput | Enables efficient processing of multiple closely-spaced wafers simultaneously. |

| Trade-off: Slower Speed | Lower pressure reduces deposition rate, prioritizing quality over speed. |

| Trade-off: High Temperature | Requires high heat (often >600°C), limiting use with temperature-sensitive materials. |

Need to deposit high-quality, uniform thin films for your semiconductor or advanced materials project?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for processes like LPCVD. Our expertise ensures you achieve the film uniformity, conformality, and purity critical for high-performance devices.

Contact our experts today to discuss how our solutions can enhance your deposition process and manufacturing yield.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty