Physical Vapor Deposition (PVD) offers a powerful combination of material versatility, high-performance characteristics, and environmental safety. This vacuum-based coating process allows for the deposition of exceptionally thin, hard, and durable films onto a vast array of substrates. The key advantages stem from its ability to manipulate materials at an atomic level, creating surface properties that are often impossible to achieve through other methods.

PVD's fundamental advantage is its ability to engineer a material's surface for superior performance without altering the core properties of the underlying component. It provides a solution for wear, friction, and corrosion while being an environmentally responsible technology.

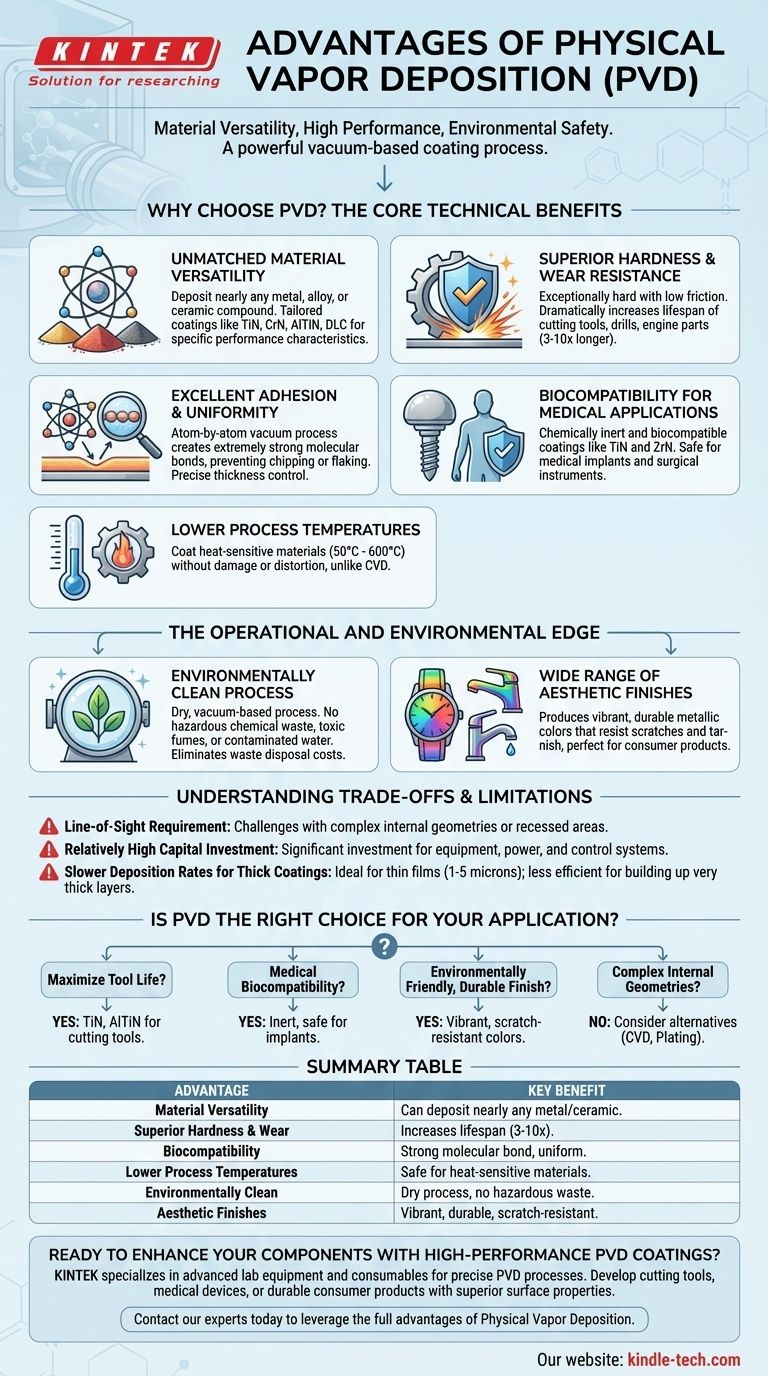

Why Choose PVD? The Core Technical Benefits

Physical Vapor Deposition is not just a single method but a family of processes (like sputtering and evaporation) that share common principles. These principles give rise to several key technical advantages.

Unmatched Material Versatility

PVD can deposit nearly any metal, alloy, or ceramic compound. This includes materials like titanium nitride (TiN), chromium nitride (CrN), aluminum titanium nitride (AlTiN), and diamond-like carbon (DLC). This allows engineers to select a coating specifically tailored to the desired performance characteristic.

Superior Hardness and Wear Resistance

PVD coatings are exceptionally hard and have a low coefficient of friction. This dramatically increases the lifespan of tools and components subjected to high wear, such as cutting tools, drills, molds, and engine parts. A coated tool can often last three to ten times longer than an uncoated one.

Excellent Adhesion and Uniformity

Because PVD is an atom-by-atom deposition process in a vacuum, the bond between the coating and the substrate is extremely strong at a molecular level. This prevents the coating from chipping or flaking. The process also allows for very precise control over film thickness, ensuring a uniform layer.

Biocompatibility for Medical Applications

Many PVD coatings, such as Titanium Nitride (TiN) and Zirconium Nitride (ZrN), are chemically inert and biocompatible. This makes them an excellent choice for medical implants, surgical instruments, and dental devices, as they will not react with the human body.

Lower Process Temperatures

Compared to alternative methods like Chemical Vapor Deposition (CVD), PVD processes can be run at much lower temperatures (typically between 50°C and 600°C). This allows for the coating of heat-sensitive materials, such as plastics, aluminum, and hardened steels, without damaging or distorting them.

The Operational and Environmental Edge

Beyond its technical performance, PVD holds significant advantages in its operational and environmental impact, making it a modern and sustainable choice.

An Environmentally Clean Process

PVD is a completely dry, vacuum-based process. Unlike traditional wet-plating methods like chrome plating, it produces no hazardous chemical waste, no toxic fumes, and no contaminated water. This eliminates the significant costs and risks associated with hazardous waste disposal.

Wide Range of Aesthetic Finishes

The PVD process can produce a vast spectrum of vibrant, metallic colors that are not just decorative but also highly durable. This makes it a popular choice for consumer products like watches, faucets, and hardware, where the finish must resist scratches and tarnish for years.

Understanding the Trade-offs and Limitations

No technology is perfect for every application. To make an informed decision, it's critical to understand the constraints of PVD.

The Line-of-Sight Requirement

PVD is a "line-of-sight" process, meaning the coating material travels in a straight line from the source to the substrate. This makes it challenging to coat complex internal geometries or deeply recessed areas. Achieving uniform coverage on complex parts requires sophisticated fixtures and rotation within the chamber.

Relatively High Capital Investment

The vacuum chambers, power supplies, and control systems required for PVD represent a significant capital investment. This can make the process less cost-effective for very simple, low-value components where the performance gains are not critical.

Slower Deposition Rates for Thick Coatings

While PVD is ideal for thin films (typically 1-5 microns), it can be slower than processes like electroplating for building up very thick layers. The process is optimized for performance-enhancing thin films, not for bulk material deposition.

Is PVD the Right Choice for Your Application?

Choosing a coating technology depends entirely on your end goal. PVD excels where surface performance is the primary driver.

- If your primary focus is maximizing tool life and wear resistance: PVD coatings like TiN or AlTiN are the industry standard for cutting tools, punches, and molds.

- If your primary focus is biocompatibility for medical devices: PVD offers inert, safe, and durable coatings ideal for implants and surgical instruments.

- If your primary focus is an environmentally friendly, durable decorative finish: PVD provides a vast range of vibrant colors with much greater scratch resistance than paint or traditional plating.

- If you are coating complex internal geometries: You must carefully consider the line-of-sight limitations and may need to explore alternative methods like CVD or specialized plating.

Ultimately, PVD empowers you to fundamentally redesign the surface of a component to meet performance demands the bulk material alone could never achieve.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Versatility | Can deposit nearly any metal, alloy, or ceramic compound. |

| Superior Hardness & Wear | Dramatically increases tool and component lifespan (3-10x). |

| Excellent Adhesion | Strong molecular bond ensures uniform, durable coating. |

| Biocompatibility | Ideal for medical implants and surgical instruments. |

| Lower Process Temperatures | Safe for coating heat-sensitive materials like plastics. |

| Environmentally Clean | Dry, vacuum-based process with no hazardous waste. |

| Aesthetic Finishes | Produces vibrant, durable, and scratch-resistant colors. |

Ready to enhance your components with high-performance PVD coatings?

KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Whether you're developing cutting tools, medical devices, or durable consumer products, our solutions can help you achieve superior surface properties like unmatched hardness, wear resistance, and biocompatibility.

Contact our experts today to discuss how we can support your laboratory's specific coating needs and help you leverage the full advantages of Physical Vapor Deposition.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the process of pyrolysis in biomass energy? A Guide to Converting Biomass into Biofuel, Biochar, and Syngas

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What temperature should Rotavap be? Master the Delta 20 Rule for Safe, Efficient Solvent Removal

- Is pyrolysis of plastic harmful? The Truth About Toxic Byproducts and Environmental Risks

- What is the function of a constant temperature orbital shaker in biomass hydrolysis? Maximize Sugar Yields

- What is the composition of pyrolysis liquids? A Deep Dive into Bio-Oil's Chemical Makeup

- How does heat treatment affect hardness? Master the Art of Controlled Hardening and Softening