In short, press forging holds a distinct advantage over drop forging due to its application of continuous, controlled pressure. Unlike the violent, high-speed impact of a drop hammer, a forging press slowly squeezes the metal, allowing the force to penetrate deeper and more uniformly throughout the workpiece. This results in superior internal grain structure, better mechanical properties, and the ability to form larger or more complex components with higher precision.

The core difference is control versus speed. Press forging is a deliberate, controlled process ideal for part integrity and complex shapes, whereas drop forging is a rapid, impact-based process optimized for production speed and simpler forms.

The Fundamental Difference: Squeeze vs. Strike

To understand the advantages, you must first grasp the core mechanical difference between the two processes. They do not shape metal in the same way.

The Continuous Squeeze of Press Forging

A hydraulic forging press applies a continuous, controlled force to the workpiece. Think of it as slowly and powerfully closing a fist around a piece of clay.

This method allows the deformation to occur gradually, giving the material's grain structure time to flow and reorient. The force is not a momentary impact but a sustained pressure that works its way through the entire volume of the metal.

The High-Velocity Impact of Drop Forging

Drop forging, by contrast, uses the kinetic energy of a falling hammer (or a powered hammer) to strike the workpiece. This is a single, massive, high-velocity blow.

The energy is delivered almost instantaneously. While effective for shaping the surface and near-surface areas, the effect may not be as uniform or penetrate as deeply as the slow pressure of a press.

Key Advantages Driven by Controlled Pressure

The "squeeze vs. strike" principle gives press forging several critical advantages in specific applications.

Deeper, More Uniform Deformation

Because the force is applied slowly, it fully penetrates the workpiece. This ensures a consistent, refined grain structure throughout the component's cross-section, not just near the surface.

This leads to superior and more predictable mechanical properties, such as strength and fatigue resistance, which is critical for high-performance applications.

Superior Process Control

Hydraulic presses offer near-infinite control over the process. The operator can precisely manage the forming speed and the amount of force applied throughout the entire stroke.

This adaptability is essential when working with sensitive, high-strength alloys (like titanium or nickel-based superalloys) that can crack or develop poor properties if deformed too quickly.

Enhanced Die Longevity

The dies used in forging are subjected to immense stress. In drop forging, the repeated, violent impact creates significant shock and thermal fatigue, wearing dies out faster.

Press forging applies force without the high-velocity shock. This smoother loading cycle significantly reduces die wear and increases their operational lifespan, lowering long-term tooling costs.

Suitability for Large Components

The large stroke and sustained power of a hydraulic press make it the ideal choice for producing very large forgings, such as industrial shafts, turbine discs, or structural components for aerospace. A hammer simply cannot deliver enough energy in a single blow to deform such a massive volume of metal uniformly.

Understanding the Trade-offs

Choosing press forging is not without its considerations. Its advantages in quality and control come at the cost of other factors.

Cycle Time and Production Rate

The primary trade-off is speed. The deliberate, controlled stroke of a press is inherently slower than the rapid succession of blows from a drop hammer.

For high-volume manufacturing of smaller, simpler parts where speed is the dominant cost driver, drop forging is almost always the more economical choice.

Equipment and Operational Costs

Large hydraulic presses are massive, complex, and expensive pieces of machinery. Their initial capital investment is typically much higher than that of a forging hammer.

Furthermore, their slower cycle time can lead to higher operational costs per part, as the workpiece spends more time being heated and handled.

Heat Loss and Scale Formation

Because the press forging process is slower, the hot workpiece is in contact with the cooler dies for a longer duration. This can lead to greater heat loss and the formation of surface scale (oxidation).

While manageable with modern techniques, it is a factor that must be controlled to ensure proper final dimensions and surface finish.

Making the Right Choice for Your Application

Your decision must be guided by the final requirements of the component.

- If your primary focus is maximum material integrity and performance: Choose press forging for its ability to create a uniform and refined internal grain structure.

- If your primary focus is high-volume, cost-effective production of smaller parts: Drop forging is likely the better choice due to its rapid cycle times.

- If your primary focus is forming very large components or working with sensitive alloys: The control and deep-penetrating power of press forging are non-negotiable.

Ultimately, selecting the right forging method is about precisely matching the process capabilities to your material and performance goals.

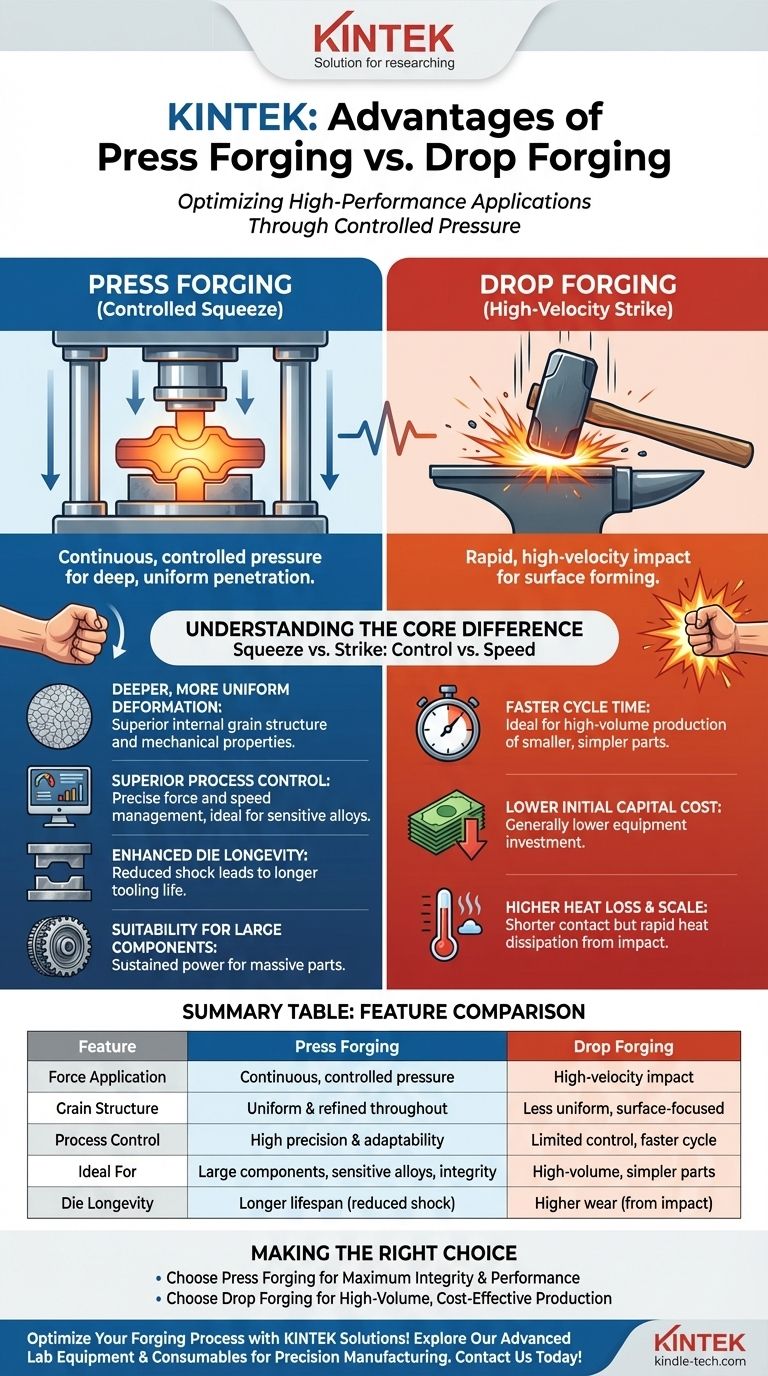

Summary Table:

| Feature | Press Forging | Drop Forging |

|---|---|---|

| Force Application | Continuous, controlled pressure | High-velocity impact |

| Grain Structure | Uniform and refined throughout | Less uniform, surface-focused |

| Process Control | High precision and adaptability | Limited control, faster cycle |

| Ideal For | Large components, sensitive alloys, high integrity | High-volume, simpler parts |

| Die Longevity | Longer lifespan due to reduced shock | Higher wear from impact |

Need to optimize your forging process for superior part quality?

At KINTEK, we specialize in providing advanced lab equipment and consumables that support precision manufacturing and material testing. Whether you're working with high-strength alloys or require equipment for quality control in forging, our solutions are designed to enhance your operational efficiency and ensure material integrity.

Let our experts help you select the right tools to achieve deeper deformation, better mechanical properties, and longer die life. Contact us today to discuss your specific needs and discover how KINTEK can support your success in high-performance forging applications.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Special Heat Press Mold for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What role do laboratory hydraulic presses and stainless steel molds play in the pre-treatment of LLZO powders? | KINTEK

- What is the role of a laboratory hydraulic press in the preparation of LiTa2PO8 (LTPO) ceramic pellets? | KINTEK

- What is the function of an ultra-high pressure hydraulic press in ceramic composites? Achieving High-Density Densification

- Why is my hydraulic press not retracting? Diagnose and Fix the Blocked Fluid Return Path

- What is the difference between hydro pneumatic press and hydraulic press? Choose the Right Press for Your Application

- What is the primary function of a high-tonnage uniaxial hydraulic press? Optimize High-Entropy Alloy Consolidation

- How does a laboratory hydraulic press address ion transport challenges in LPSC batteries? Optimize Densification Now

- What is the primary function of a hydraulic press in SiC/Al-Zn-Mg-Cu extrusion? Mastering Material Deformation