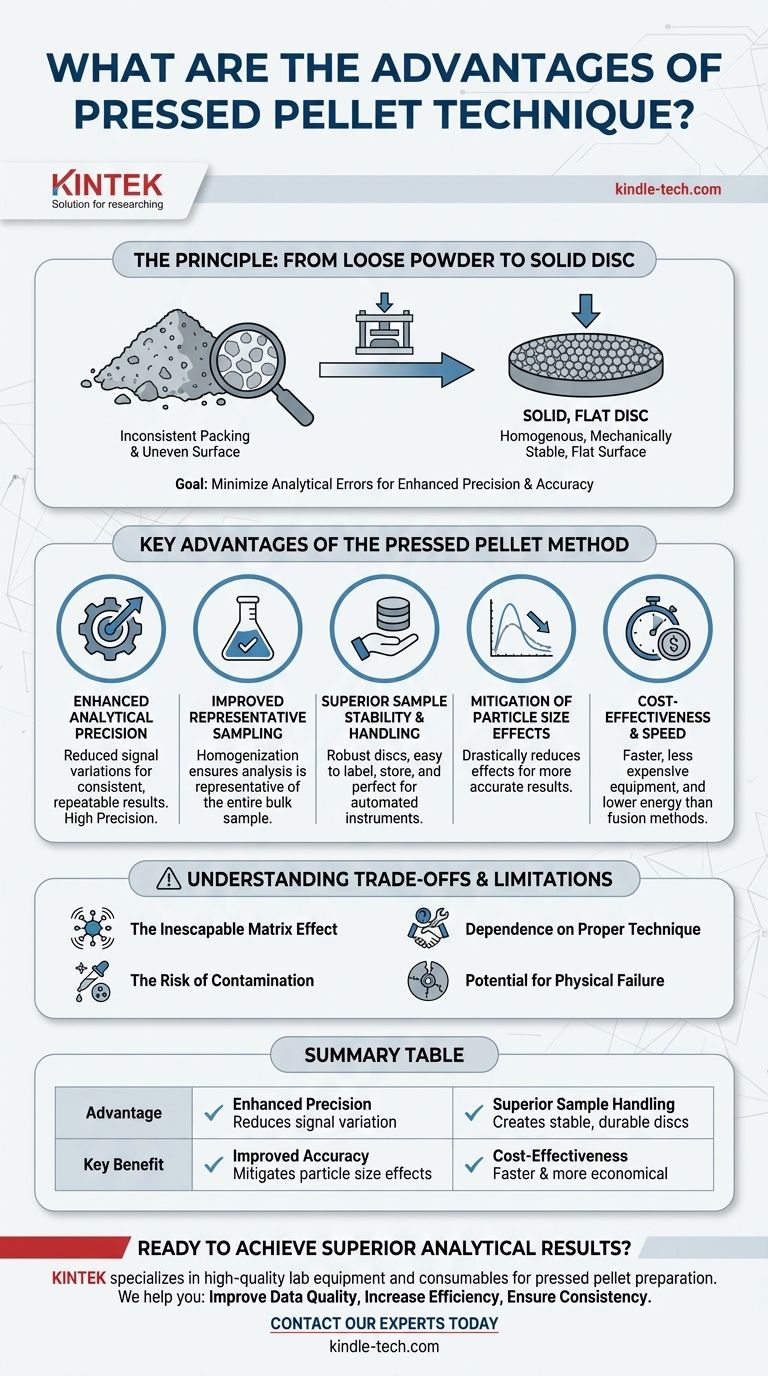

At its core, the pressed pellet technique is a method for transforming a powdered sample into a solid, flat disc to improve the quality of analytical measurements. Its primary advantages are significantly enhanced precision, better accuracy, and superior sample handling, particularly for spectroscopic methods like X-Ray Fluorescence (XRF) and Fourier-Transform Infrared Spectroscopy (FTIR).

The fundamental goal of the pressed pellet technique is to create a homogenous and mechanically stable sample with a perfectly flat surface, thereby minimizing analytical errors caused by surface irregularities and inconsistent sample density.

The Principle: Why Pressing a Pellet Works

The pressed pellet method converts a non-ideal loose powder into a near-ideal solid sample for analysis. This physical transformation is the source of its main benefits.

From Loose Powder to a Solid Disc

Loose powders suffer from inconsistent packing and an uneven surface, which can scatter the analytical beam (X-rays or infrared light) unpredictably.

By applying high pressure, the powder particles are compacted, eliminating voids and creating a dense, uniform disc. This ensures the analytical instrument sees a consistent and representative sample surface every time.

The Critical Role of Binders

Often, a binding agent or grinding aid (like a wax or cellulose) is mixed with the sample before pressing.

This binder acts like a glue, helping the sample particles adhere to one another. This prevents the finished pellet from cracking and makes it more durable for handling and storage.

Key Advantages of the Pressed Pellet Method

The benefits of this technique directly address common sources of error in powder analysis, leading to more reliable and repeatable results.

Enhanced Analytical Precision

A flat, dense surface reduces variations in the signal measured by the spectrometer. This means that if you measure the same pellet multiple times, you will get very consistent results, which is the definition of high precision.

Improved Representative Sampling

The process requires the sample to be finely ground and thoroughly mixed, often with a binder. This homogenization ensures that the small area analyzed by the instrument is representative of the entire bulk sample, reducing sampling errors.

Superior Sample Stability and Handling

Pressed pellets are solid, robust, and easy to handle. They can be labeled, stored for long periods for archival purposes, and are perfectly suited for automated sample changers in modern instruments without risk of spilling.

Mitigation of Particle Size Effects

In loose powders, large particles can disproportionately affect the analytical signal compared to small ones. The required fine grinding and high-pressure compaction in the pellet method drastically reduce these particle size effects, leading to more accurate results.

Cost-Effectiveness and Speed

Compared to alternative methods like fusion (where the sample is dissolved in molten glass), pressing pellets is typically faster, requires less expensive equipment, and consumes less energy. This makes it ideal for high-throughput quality control environments.

Understanding the Trade-offs and Limitations

While powerful, the pressed pellet technique is not without its challenges. Objectivity requires acknowledging where it can fall short.

The Inescapable Matrix Effect

Pressing a sample does not change its chemical composition. Therefore, matrix effects, where the presence of certain elements influences the signal from other elements, are still a major factor that must be corrected for with appropriate calibration standards.

The Risk of Contamination

Any substance added to the sample, such as a binder or grinding aid, can introduce contaminants. Likewise, the grinding equipment itself can be a source of contamination if not cleaned properly or if it is made of materials that can abrade into the sample.

Dependence on Proper Technique

The quality of the final result is highly dependent on the preparation procedure. Inconsistent grinding, improper mixing, or incorrect pressure can all lead to a poor-quality pellet and, consequently, inaccurate results.

Potential for Physical Failure

Some materials are difficult to press and may result in cracked or fragile pellets that cannot be analyzed reliably. This requires careful optimization of the binder, pressure, and dwell time.

Making the Right Choice for Your Analysis

Choosing the correct sample preparation technique depends entirely on your analytical goals, the nature of your sample, and your required level of accuracy.

- If your primary focus is high-throughput routine analysis and process control: The speed and cost-effectiveness of pressed pellets make them the superior choice.

- If your primary focus is the highest possible accuracy for certification or research: Consider fusion, as it completely eliminates particle size and mineralogical effects, though at a higher cost and complexity.

- If your primary focus is preserving a very small or precious sample: Direct analysis of loose powder may be necessary, but you must accept the trade-off of lower precision and accuracy.

Ultimately, when executed correctly, the pressed pellet technique provides an exceptional balance of sample quality, cost, and speed for a vast range of analytical applications.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Enhanced Precision | Reduces signal variation for consistent, repeatable results. |

| Improved Accuracy | Mitigates particle size effects through homogenization. |

| Superior Sample Handling | Creates stable, durable discs for easy handling and storage. |

| Cost-Effectiveness | Faster and more economical than fusion methods for routine QC. |

Ready to achieve superior analytical results in your lab?

The pressed pellet technique is a cornerstone of reliable sample preparation. KINTEK specializes in providing the high-quality lab equipment and consumables—including pellet presses, dies, and pure binders—you need to implement this method effectively.

We help you:

- Improve Data Quality: Achieve the homogeneity and flat surface essential for precise XRF and FTIR measurements.

- Increase Efficiency: Streamline your sample preparation for high-throughput environments.

- Ensure Consistency: Get reliable results batch after batch with robust equipment.

Let's optimize your sample preparation process. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms