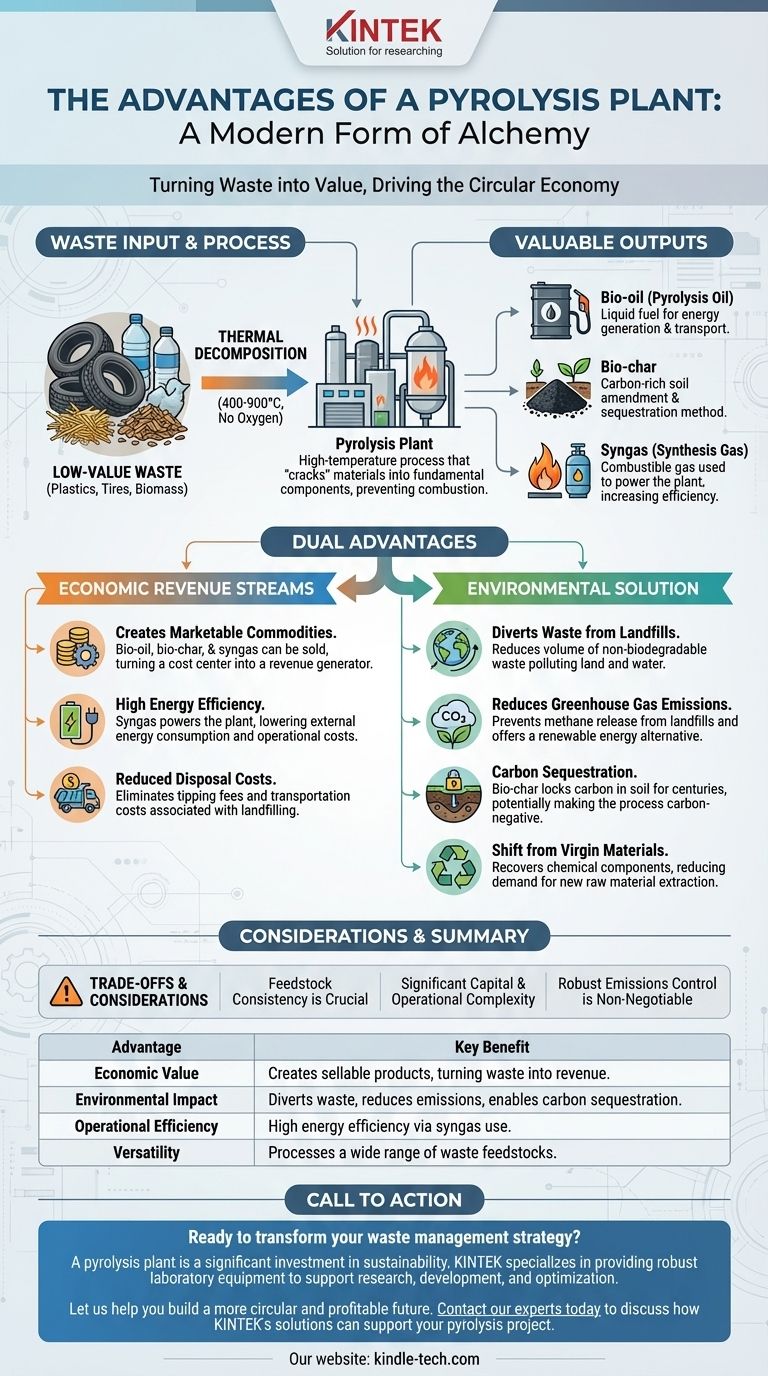

At its core, a pyrolysis plant is a modern form of alchemy. It takes low-value or costly waste materials—like plastics, old tires, and agricultural residue—and transforms them into valuable commodities. The primary advantages are twofold: it provides a powerful environmental solution for waste management while simultaneously creating new economic revenue streams from the resulting energy products.

A pyrolysis plant fundamentally changes the equation for waste. Instead of treating waste as a liability to be buried, it re-frames it as a resource to be converted into high-value products like bio-oil, bio-char, and syngas, driving progress toward a circular economy.

How Pyrolysis Creates Value from Waste

To understand the advantages of a pyrolysis plant, you must first understand the process. It is a technology designed for resource recovery through thermochemical conversion.

The Core Principle: Thermal Decomposition

Pyrolysis is the process of heating organic materials, such as plastics or biomass, to high temperatures (400-900°C) in an environment with little to no oxygen.

The absence of oxygen is critical. It prevents the material from burning (combustion) and instead causes it to thermally decompose, or "crack," into its fundamental components.

A Versatile Feedstock Portfolio

One of the technology's key strengths is its flexibility. A pyrolysis plant can process a wide range of organic and polymeric wastes that would otherwise end up in a landfill.

This includes post-consumer plastics, scrap tires, rubber waste, agricultural residues, wood waste, and other forms of biomass. This versatility allows it to adapt to various local waste streams.

The Three Primary Outputs

The decomposition process consistently yields three valuable product streams from the initial feedstock.

- Bio-oil (Pyrolysis Oil): A liquid fuel similar to crude oil that can be refined into transportation fuels or used in boilers and furnaces for heat and power generation.

- Bio-char: A stable, carbon-rich solid. It is a powerful soil amendment that improves water retention and agricultural yields, and it also serves as a method for carbon sequestration.

- Syngas (Synthesis Gas): A mixture of combustible gases. This gas is often used on-site to power the pyrolysis plant itself, making the process highly energy-efficient and reducing operational costs.

The Economic Advantages of Resource Conversion

By turning a disposal problem into a production opportunity, pyrolysis offers compelling financial benefits.

Creating Marketable Commodities

The most significant economic advantage is the creation of sellable products. Bio-oil, bio-char, and even excess syngas can be sold, turning a waste management cost center into a revenue-generating operation.

High Energy Efficiency

Modern pyrolysis plants are designed for high energy efficiency. The ability to use the produced syngas to fuel the system dramatically lowers the plant's external energy consumption and operating expenses.

Reduced Landfill and Disposal Costs

For municipalities and private companies, landfilling waste involves significant "tipping fees" and transportation costs. By diverting this waste to a pyrolysis plant, these direct costs are immediately eliminated.

The Environmental Case for Pyrolysis

Beyond the economics, pyrolysis presents a strong environmental argument for sustainable waste management.

Diverting Waste from Landfills

Pyrolysis directly addresses the growing crisis of limited landfill space. It significantly reduces the volume of non-biodegradable waste, such as plastics and tires, that pollutes land and water.

Reducing Greenhouse Gas Emissions

The technology offers a double benefit for emissions reduction. It provides a renewable energy alternative to fossil fuels and prevents the release of methane, a potent greenhouse gas, which is generated by organic waste decomposing in landfills.

Carbon Sequestration via Biochar

Bio-char is a form of inert, long-lasting carbon. When added to soil, it effectively locks that carbon away for centuries, removing it from the atmospheric cycle. This makes pyrolysis a carbon-negative technology in certain applications.

A Shift Away from Virgin Materials

By recovering the chemical components of materials like plastics and rubber, pyrolysis reduces the demand for virgin raw materials. This lessens the environmental impact associated with extraction, processing, and transportation.

Understanding the Trade-offs and Considerations

While powerful, pyrolysis technology is not a universal solution. An objective assessment requires understanding its operational realities.

Feedstock Consistency is Crucial

The quality and consistency of the waste input directly impact the quality and yield of the output products. Contaminated or highly mixed waste streams can complicate the process and reduce the value of the end products.

Capital Investment and Operational Complexity

Pyrolysis plants are sophisticated industrial facilities that require significant upfront capital investment. They also demand skilled operators to manage the process parameters and ensure safety and efficiency.

Emissions Control is Non-Negotiable

Although the core process is low-oxygen, the entire system requires robust emission cleaning and control technology. This is essential for managing any potential byproducts and ensuring compliance with environmental regulations.

Making the Right Choice for Your Goal

The advantages of a pyrolysis plant are best applied when aligned with a clear objective.

- If your primary focus is waste management and cost reduction: The key advantage is its ability to divert massive volumes of waste from landfills, eliminating tipping fees and creating revenue from a former liability.

- If your primary focus is renewable energy production: The technology's main benefit is the consistent creation of bio-oil and syngas, which serve as direct, locally-sourced replacements for fossil fuels.

- If your primary focus is meeting environmental and carbon targets: The most powerful advantage is the combination of reducing landfill methane emissions and actively sequestering carbon in the soil through biochar.

Ultimately, a pyrolysis plant provides a practical and proven tool for building a more sustainable and circular economy.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Economic Value | Creates sellable products (bio-oil, bio-char, syngas) from waste, turning a cost into revenue. |

| Environmental Impact | Diverts waste from landfills, reduces greenhouse gas emissions, and enables carbon sequestration. |

| Operational Efficiency | High energy efficiency; syngas produced can power the plant, lowering operational costs. |

| Versatility | Processes a wide range of feedstocks, including plastics, tires, and agricultural waste. |

Ready to transform your waste management strategy and unlock new revenue streams?

A pyrolysis plant is a significant investment in sustainability and profitability. At KINTEK, we specialize in providing robust laboratory equipment and consumables to support the research, development, and optimization of pyrolysis processes. Whether you are in the testing phase or scaling up your operations, our precise and reliable tools are designed to meet the demanding needs of modern laboratories.

Let us help you build a more circular and profitable future. Contact our experts today to discuss how KINTEK's solutions can support your pyrolysis project.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process