At its core, ball milling is a highly versatile process used across countless industries for grinding materials into fine powders and for synthesizing new materials altogether. Its applications range from large-scale industrial tasks like cement production and mineral ore processing to high-tech research in pharmaceuticals and nanotechnology. The key to its widespread use is its ability to effectively process an incredibly diverse range of materials.

The true value of ball milling lies not in a single function, but in its fundamental versatility. By controlling the simple mechanical forces of impact and attrition, it can be adapted to achieve goals as different as simple grinding, creating novel alloys, and producing nanoparticles from nearly any starting material.

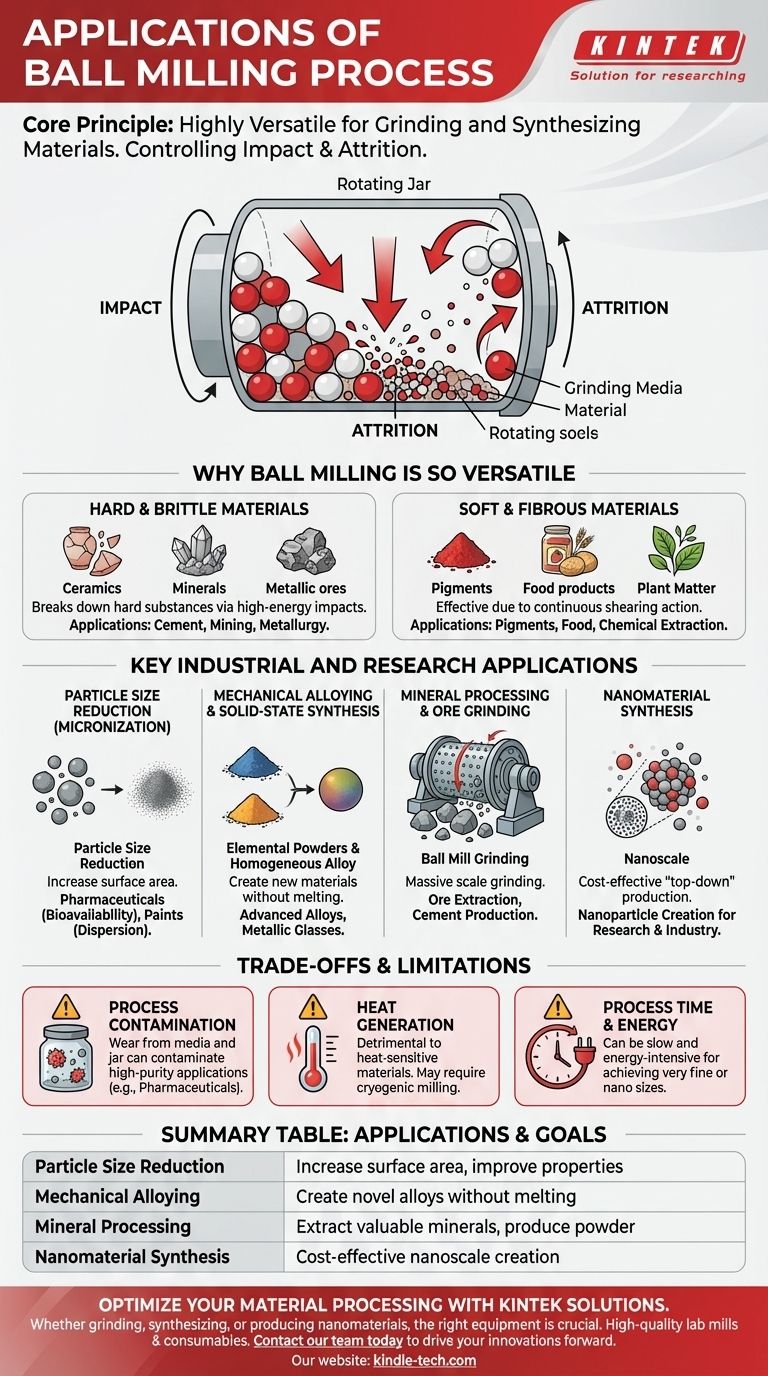

The Core Principle: Why Ball Milling is So Versatile

The power of ball milling comes from its simple yet effective mechanism. A sealed jar is partially filled with the material to be processed and a grinding medium, typically hard ceramic or steel balls. The jar is then rotated, causing the balls to cascade and fall, crushing and grinding the material.

The Mechanism of Action

The process works through two primary forces: impact and attrition. As the balls are lifted by the rotating jar, they fall and collide with the material, creating high-energy impacts that fracture it. Simultaneously, the rolling and sliding of the balls against each other and the jar wall create shearing (attrition) forces that further reduce particle size.

Processing Hard and Brittle Materials

Ball milling excels at breaking down extremely hard and brittle substances. The high-energy impacts are perfect for fracturing ceramics, minerals, and metallic ores that resist other forms of grinding. This makes it a foundational technology in mining, metallurgy, and cement manufacturing.

Processing Soft and Fibrous Materials

Conversely, the combination of impact and attrition is also effective for soft, ductile, or fibrous materials. For materials that might deform rather than break under pure impact, the continuous shearing action helps tear and grind them down. This capability is leveraged in industries processing pigments, food products, and even plant matter for chemical extraction.

Key Industrial and Research Applications

This versatility translates into a wide array of specific applications, falling into a few primary categories. Each application leverages the same core principle for a different industrial or scientific outcome.

Particle Size Reduction (Micronization)

This is the most common application. Reducing particle size increases surface area, which can dramatically alter a material's properties.

In pharmaceuticals, it's used to increase the dissolution rate and bioavailability of poorly soluble drugs. In the pigment and paint industry, it ensures uniform color and dispersion.

Mechanical Alloying and Solid-State Synthesis

Ball milling can be used to create new materials entirely. By milling different elemental powders together for extended periods, the repeated fracturing and cold-welding of particles can produce homogenous alloys at room temperature.

This process, known as mechanical alloying, is critical for creating materials that are difficult or impossible to produce through traditional melting methods, such as amorphous metals (metallic glasses) and advanced composites.

Mineral Processing and Ore Grinding

On a massive industrial scale, ball mills are used to grind crushed ore for the extraction of valuable minerals. In cement production, it is the primary method for grinding clinker into the fine powder that becomes finished cement.

Nanomaterial Synthesis

By carefully controlling milling parameters like time, speed, and ball-to-powder ratio, ball milling can be used to reduce particle sizes down to the nanoscale. This "top-down" approach is a cost-effective method for producing large quantities of certain nanoparticles for research and industrial use.

Understanding the Trade-offs and Limitations

While powerful, ball milling is not without its challenges. An objective assessment requires understanding its potential downsides.

Process Contamination

The most significant drawback is contamination from the grinding media and the jar itself. The constant impact and abrasion can cause microscopic particles of the balls (e.g., steel, zirconia, tungsten carbide) to wear off and mix with the processed powder. This is a critical concern in high-purity applications like pharmaceuticals.

Heat Generation

The mechanical energy of milling is largely converted into heat. This temperature increase can be detrimental to heat-sensitive materials, potentially causing degradation, phase changes, or unwanted chemical reactions. For such materials, cryogenic milling (milling at very low temperatures) is often required.

Process Time and Energy Consumption

Achieving very fine or nano-sized particles can be a slow and energy-intensive process, sometimes requiring milling for many hours or even days. This makes it less efficient for applications where speed is the absolute top priority and a coarser powder is acceptable.

Making the Right Choice for Your Goal

Selecting the right process depends entirely on your material and desired outcome. Ball milling is a powerful tool when its strengths are aligned with the project's needs.

- If your primary focus is cost-effective size reduction of hard materials: Ball milling is an industry-standard, reliable choice for processing minerals, ores, and ceramics.

- If your primary focus is creating novel alloys without melting: Mechanical alloying via a ball mill is one of the most effective and accessible methods available.

- If your primary focus is processing high-purity or temperature-sensitive compounds: Proceed with caution, carefully select non-reactive grinding media, and consider cryogenic options to mitigate heat and contamination.

By understanding these core applications and inherent trade-offs, you can effectively determine if ball milling is the right solution for your specific material processing challenge.

Summary Table:

| Application Category | Key Use Cases | Primary Goal |

|---|---|---|

| Particle Size Reduction | Pharmaceuticals, Paints, Pigments | Increase surface area, improve dissolution/dispersion |

| Mechanical Alloying | Advanced Alloys, Metallic Glasses | Create new materials without melting |

| Mineral Processing | Ore Grinding, Cement Production | Extract valuable minerals, produce fine powders |

| Nanomaterial Synthesis | Nanoparticle Production | Cost-effective top-down nanoscale particle creation |

Optimize Your Material Processing with KINTEK Solutions

Whether you're grinding hard materials, synthesizing novel alloys, or producing nanomaterials, the right ball milling equipment is crucial for success. KINTEK specializes in high-quality lab mills, grinding media, and consumables designed to meet the precise demands of your application while minimizing contamination and heat generation.

Our experts can help you select the ideal milling solution to enhance your research or production efficiency.

Contact our team today to discuss your specific needs and discover how KINTEK's reliable laboratory equipment can drive your innovations forward.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?