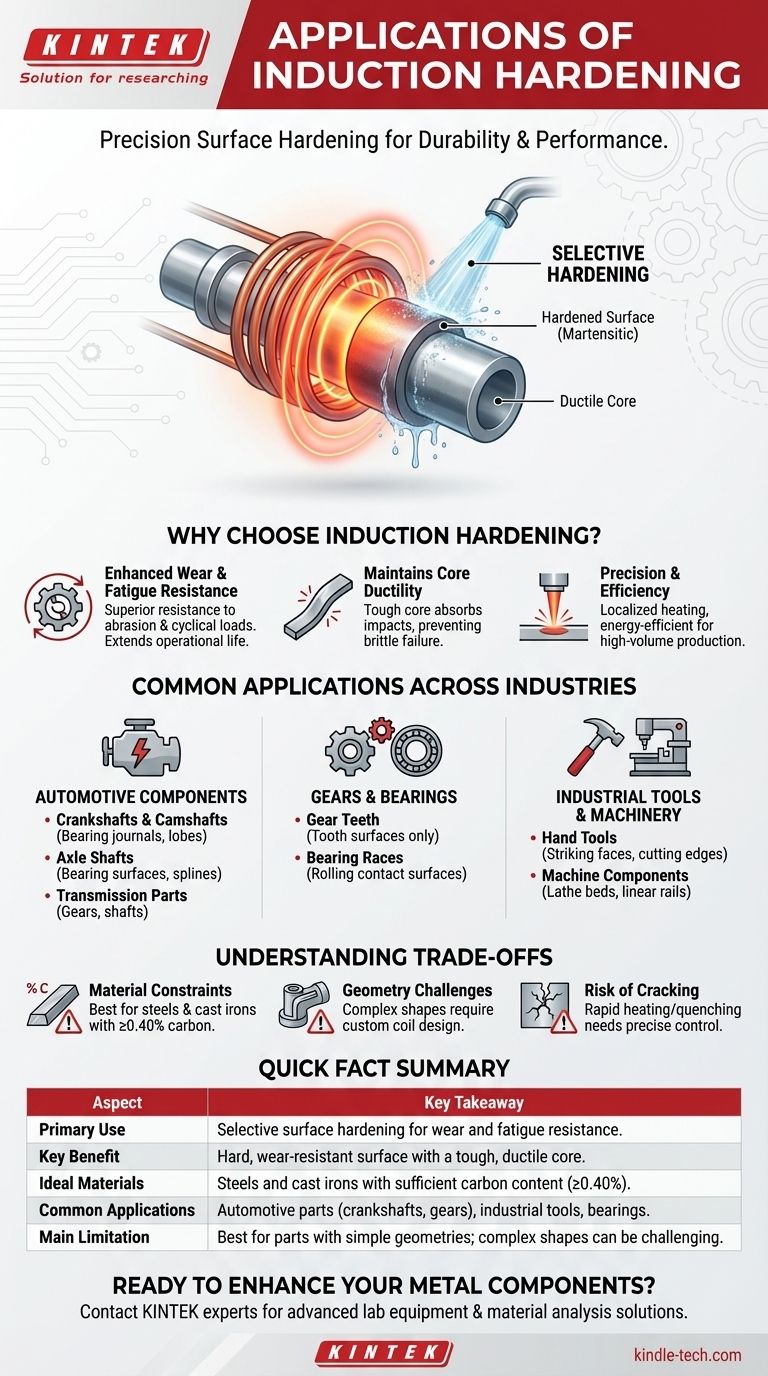

At its core, induction hardening is used to create highly durable, wear-resistant surfaces on metal components, particularly in demanding industrial and automotive applications. Its primary use is on parts like crankshafts, camshafts, gears, and axles, where specific areas must withstand intense friction and stress while the rest of the component remains tough and resilient.

The true value of induction hardening isn't just making a part harder; it's the ability to selectively harden only the critical surfaces. This precision allows engineers to create components with a hard, wear-resistant outer shell and a ductile, tough inner core, achieving the best of both properties in a single part.

Why Choose Induction Hardening?

Induction hardening is a form of surface heat treatment. It solves the fundamental engineering challenge of needing a material to be both hard (to resist wear) and tough (to resist fracture). By treating only the surface, it avoids making the entire component brittle.

The Principle of Selective Hardening

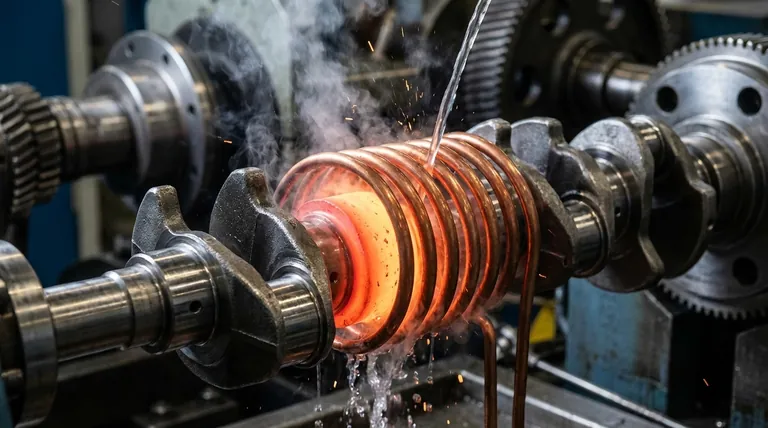

The process uses a high-frequency alternating current passed through a copper coil. This creates a powerful, rapidly changing magnetic field that heats the surface of a conductive part, like steel or cast iron, placed within it.

Once the surface reaches the required temperature, it is immediately quenched in water or another medium. This rapid heating and cooling cycle alters the steel's microstructure on the surface, making it extremely hard.

Enhancing Wear and Fatigue Resistance

The primary benefit of this hard surface is superior resistance to wear and abrasion. For components like camshafts, which are in constant contact with other parts, this dramatically extends their operational life.

Furthermore, the process creates compressive stresses in the hardened layer. This residual stress helps counteract tensile forces that lead to fatigue cracks, significantly improving the part's fatigue resistance under cyclical loads.

Maintaining Core Ductility

Because the heating is rapid and localized to the surface, the core of the component is unaffected. It retains its original, softer, and more ductile properties.

This dual-property nature is critical. The tough core can absorb impacts and handle torque without fracturing, while the hard case handles the surface wear. This prevents the kind of catastrophic brittle failure that would occur if the entire part were hardened through.

Common Applications Across Industries

The unique combination of a hard surface and a tough core makes induction hardening invaluable for high-performance mechanical parts.

Automotive Components

This is the most common application area. Parts must endure millions of cycles in demanding environments.

- Crankshafts & Camshafts: The bearing journals and lobe surfaces are hardened to resist constant friction and high contact stress.

- Axle Shafts: The body must handle torsion, but the bearing surfaces and splines require hardness for wear resistance.

- Transmission Parts: Gears and shafts are selectively hardened on their contact surfaces to prevent wear and pitting.

Gears and Bearings

For any gear system, only the tooth surfaces need to be hard. Induction hardening allows for precise treatment of the gear teeth without making the entire gear brittle, which could lead to tooth fracture under high torque. Similarly, bearing races require a hard surface to handle the rolling contact fatigue from ball or roller bearings.

Industrial Tools and Machinery

Many tools and machine parts benefit from localized hardening.

- Hand Tools: The striking face of a hammer or the cutting edge of an axe is hardened to prevent deformation.

- Machine Components: Parts like lathe beds or linear rails are hardened on their sliding surfaces to maintain precision and resist wear over time.

Understanding the Trade-offs

While powerful, induction hardening is not a universal solution. Understanding its limitations is key to using it effectively.

Material Constraints

The process works best on ferrous metals like steel and cast iron with sufficient carbon content (typically 0.40% or higher). The carbon is what allows the material's crystal structure to change and create the hard martensitic phase upon quenching.

Geometry and Coil Design

The shape of the induction coil is critical, as it dictates the heating pattern. For simple cylindrical parts, this is straightforward. However, for components with complex geometries, designing and building an effective coil can be difficult and expensive.

Risk of Cracking

The rapid heating and quenching that define the process create significant internal stresses. If not properly controlled—for example, if heating is uneven or quenching is too severe for the material—it can lead to surface cracking or distortion of the part.

Making the Right Choice for Your Goal

Deciding on a hardening process requires matching the method's strengths to your component's specific performance requirements.

- If your primary focus is extreme wear resistance on a specific surface: Induction hardening is an ideal choice, especially for high-volume production of parts with relatively simple geometries.

- If your primary focus is improving fatigue life in a high-stress area: The compressive residual stress from induction hardening provides a significant advantage over through-hardening methods.

- If your primary focus is hardening a complex shape or a non-ferrous material: You should investigate alternative methods, such as nitriding for complex shapes or other specialized surface treatments for different materials.

Ultimately, choosing induction hardening is a strategic decision to create a component that is not just strong, but intelligently engineered for its specific purpose.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Use | Selective surface hardening for wear and fatigue resistance. |

| Key Benefit | Hard, wear-resistant surface with a tough, ductile core. |

| Ideal Materials | Steels and cast irons with sufficient carbon content (≥0.40%). |

| Common Applications | Automotive parts (crankshafts, gears), industrial tools, bearings. |

| Main Limitation | Best for parts with simple geometries; complex shapes can be challenging. |

Ready to enhance the performance and lifespan of your metal components?

At KINTEK, we specialize in providing advanced lab equipment and consumables for material testing and process development, including solutions for heat treatment analysis. Whether you're developing a new component or optimizing an existing hardening process, our expertise can help you achieve superior results.

Contact our experts today to discuss how KINTEK can support your laboratory's needs in materials science and engineering.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

People Also Ask

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing