In industrial applications, nanotubes are not a theoretical novelty but a functional material used to fundamentally enhance existing products. Their primary uses are concentrated in advanced materials science, electronics, and energy storage, where they serve as powerful additives to improve strength, conductivity, and efficiency.

The true value of nanotubes lies not in a single killer application, but in their extraordinary combination of mechanical strength, electrical conductivity, and thermal performance. Mastering their use is about leveraging these nanoscale properties to fundamentally enhance macroscale products.

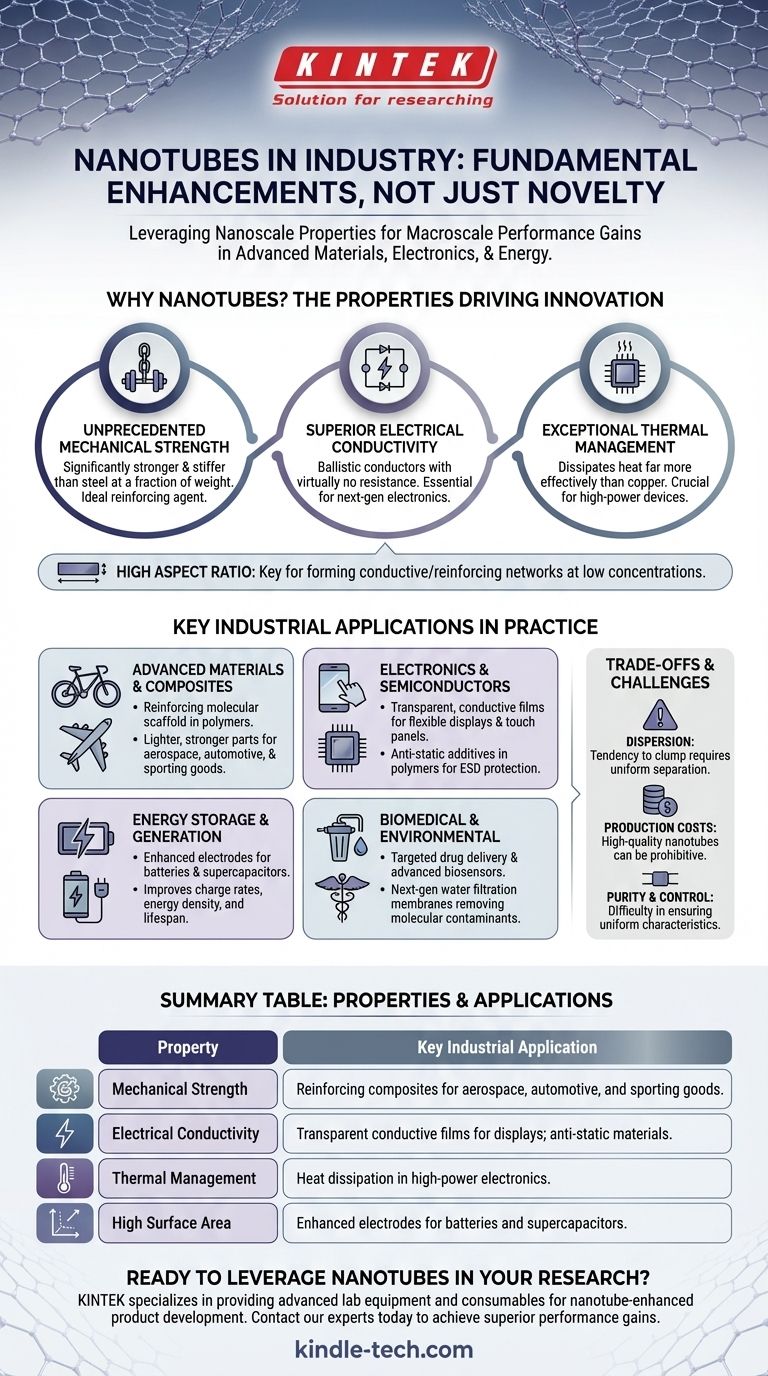

Why Nanotubes? The Properties Driving Innovation

The "special properties" of nanomaterials are what make nanotubes so valuable. Their performance metrics are often orders of magnitude greater than those of conventional bulk materials.

Unprecedented Mechanical Strength

Nanotubes, particularly carbon nanotubes (CNTs), have one of the highest tensile strengths of any known material. They are significantly stronger and stiffer than steel at a fraction of the weight.

This makes them an ideal reinforcing agent in composite materials, creating parts that are both lighter and more durable.

Superior Electrical Conductivity

Certain types of nanotubes can conduct electricity with virtually no resistance, behaving as ballistic conductors.

This property is critical for applications in next-generation electronics, from transparent conductive films for touchscreens to ultra-efficient wiring and transistors.

Exceptional Thermal Management

Nanotubes are also excellent thermal conductors, able to dissipate heat far more effectively than traditional materials like copper.

This is crucial for managing heat in compact, high-power electronics, preventing components from overheating and improving longevity.

High Aspect Ratio

Their long, thin, needle-like shape gives them a very high surface-area-to-volume ratio, also known as a high aspect ratio.

This structure is key to forming conductive or reinforcing networks within another material (like a polymer) even at very low concentrations.

Key Industrial Applications in Practice

These unique properties translate directly into tangible industrial applications that are already in the market or in late-stage development.

Advanced Materials & Composites

The most mature application is adding nanotubes to polymers. The nanotubes create a reinforcing molecular scaffold within the plastic.

This is used in high-performance sporting goods (bicycle frames, tennis rackets), aerospace components, and automotive parts to increase strength without adding weight.

Electronics & Semiconductors

Nanotubes are used to create transparent, conductive films that can replace brittle indium tin oxide (ITO) in flexible displays and touch panels.

They are also used as additives in polymers to create materials that are resistant to electrostatic discharge (ESD), which is vital for protecting sensitive electronic components.

Energy Storage & Generation

The high surface area and conductivity of nanotubes make them excellent for enhancing the electrodes in batteries and supercapacitors.

They create a conductive network that improves charge and discharge rates, increases energy density, and extends the overall lifespan of the storage device.

Biomedical & Environmental Fields

While many applications are still in research, nanotubes are being developed for highly targeted drug delivery systems and as core components in advanced biosensors.

Their unique structure is also being explored for next-generation water filtration membranes, capable of removing contaminants at the molecular level.

Understanding the Trade-offs and Challenges

Despite their immense potential, nanotubes are not a simple drop-in solution. Their adoption has been tempered by significant manufacturing and implementation hurdles.

The Problem of Dispersion

Nanotubes have a strong tendency to clump together due to van der Waals forces. If they are not properly separated and dispersed within a host material, their benefits are completely lost.

Achieving uniform dispersion at an industrial scale remains a primary technical challenge.

High Production Costs

The cost of producing high-purity, high-quality nanotubes has historically been a barrier to widespread use. While costs have decreased significantly, they can still be prohibitive for many consumer applications.

Purity and Control

It is difficult to manufacture nanotubes with uniform characteristics (e.g., diameter, length, or electronic type). This variability can lead to inconsistent performance in sensitive applications like semiconductors.

Making the Right Choice for Your Goal

The ideal application for nanotubes depends entirely on which of their unique properties you need to leverage.

- If your primary focus is lightweight strength: Incorporate them into polymer composites for aerospace, automotive, or high-performance sporting goods.

- If your primary focus is electrical performance: Explore their use in transparent conductive films, next-generation transistors, or as additives in anti-static materials.

- If your primary focus is energy efficiency: Investigate their role in creating higher-capacity battery electrodes or more efficient thermal interface materials.

Ultimately, successfully integrating nanotubes is about translating their remarkable nanoscale advantages into tangible, real-world performance gains.

Summary Table:

| Property | Key Industrial Application |

|---|---|

| Mechanical Strength | Reinforcing composites for aerospace, automotive, and sporting goods. |

| Electrical Conductivity | Transparent conductive films for displays; anti-static materials. |

| Thermal Management | Heat dissipation in high-power electronics. |

| High Surface Area | Enhanced electrodes for batteries and supercapacitors. |

Ready to leverage the power of nanotubes in your lab's materials or energy research? KINTEK specializes in providing the advanced lab equipment and consumables needed to develop and test next-generation nanotube-enhanced products. Our expertise supports your innovation in composites, electronics, and energy storage. Contact our experts today to discuss how we can help you achieve superior performance gains.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is sputtering in material science? A Guide to High-Quality Thin Film Deposition

- What are the semiconductor materials for thin film? A Guide to Silicon, Compounds & Oxides

- What are the applications of optical coating? Unlock Advanced Light Control for Your Industry

- What is a thin film in nano science? The Engineered Layer Powering Modern Technology

- What are the natural sources of graphene? Unlocking the Power of Graphite, the True Precursor

- What is the chemical solution deposition technique? A Guide to Low-Cost Thin Film Fabrication

- Are carbon nanotubes eco friendly? A Lifecycle View of Their Environmental Impact

- What are the limitations of sputtering? High Costs, Slow Speeds, and Material Damage