At their core, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are fundamentally different processes for applying a thin film to a material's surface. PVD is a physical process that transports a solid material in a vapor form onto a substrate, working in a "line-of-sight" manner. In contrast, CVD is a chemical process where precursor gases react on a heated surface to grow an entirely new material layer, allowing it to conform to complex shapes.

The choice between PVD and CVD is not about which is 'better,' but which is right for your specific application. PVD excels at depositing hard, thin coatings on surfaces that cannot tolerate high heat, while CVD is the superior method for creating uniform coatings on complex, non-line-of-sight geometries.

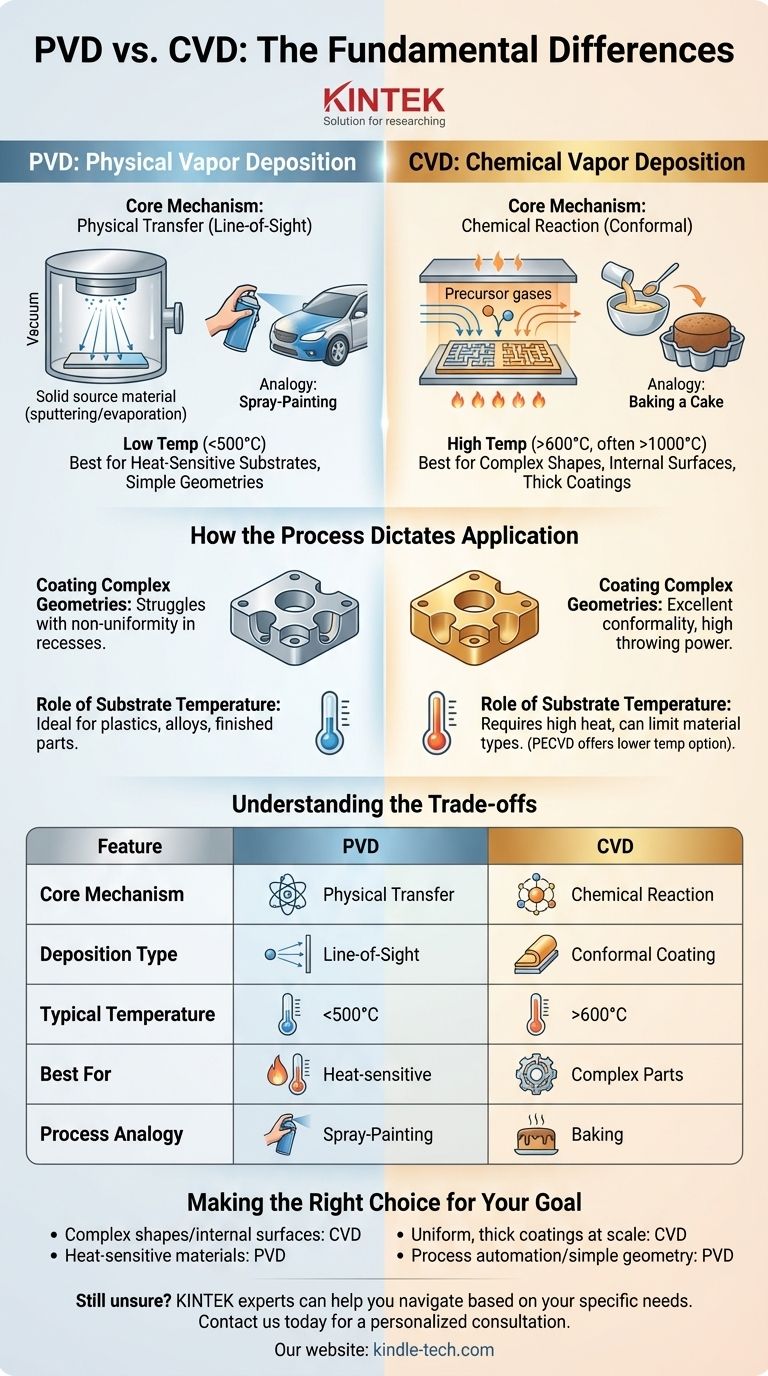

The Fundamental Difference: Physical vs. Chemical

The names "Physical Vapor Deposition" and "Chemical Vapor Deposition" directly describe their core mechanisms. This distinction is the source of all their respective advantages and disadvantages.

PVD: A "Line-of-Sight" Physical Transfer

In PVD, a solid source material is vaporized inside a vacuum chamber through methods like sputtering or evaporation. This vapor then travels in a straight line and condenses onto the substrate, forming a thin film.

Think of it like spray-painting a car. The paint only lands where you aim the nozzle; it cannot easily coat the inside of the door handles or deep crevices.

Because it is a physical transfer and not a chemical reaction, PVD can be performed at relatively low temperatures, making it suitable for a wider range of substrate materials.

CVD: A Chemical Reaction on a Surface

In CVD, the substrate is placed in a chamber and heated. Volatile precursor gases are then introduced, which react or decompose on the hot surface to form the desired solid film.

This is more like baking a cake. The ingredients (gases) mix and transform under heat to create something new (the film), filling every corner of the pan (the substrate) uniformly.

This chemical reaction typically requires high temperatures to activate. The result is a highly conformal coating that perfectly covers even complex shapes and internal surfaces.

How the Process Dictates the Application

The core mechanism of each method directly impacts its suitability for different engineering goals.

Coating Complex Geometries

CVD's primary advantage is its excellent conformality. Because the deposition is driven by a chemical gas-phase reaction, it is not a line-of-sight process.

This allows CVD to uniformly coat deep recesses, holes, and other intricate shapes with high "throwing power."

PVD, being a line-of-sight process, struggles with this. Surfaces not directly facing the vapor source will receive little to no coating, creating non-uniformity and potential points of failure.

The Role of Substrate Temperature

PVD processes generally operate at lower temperatures, often below 500°C. This makes PVD ideal for coating heat-sensitive substrates like plastics, certain alloys, or finished components that cannot risk thermal distortion.

Traditional CVD requires much higher temperatures, often exceeding 600°C or even 1000°C, to drive the chemical reactions. This can limit the types of materials that can be coated without damage or alteration.

However, a variant called Plasma-Enhanced CVD (PECVD) uses plasma to assist the chemical reaction, allowing for significantly lower substrate temperatures and broadening its range of applications.

Understanding the Trade-offs

Choosing a deposition method requires an objective look at the practical costs, safety, and complexity involved.

Cost and Throughput

The economics of PVD and CVD are nuanced. PVD often requires specialized, high-vacuum equipment, which can lead to a higher initial capital investment.

CVD can be more economical for high-volume production or for creating very thick coatings due to its characteristically high deposition rates. However, the cost of precursor gases and energy for heating can increase operational expenses.

Safety and Environmental Concerns

PVD is generally considered a cleaner process, as it does not typically involve toxic or corrosive chemicals. The primary hazard is physical, related to the integrity of the high-vacuum chamber.

CVD processes, by their nature, often utilize harmful, toxic, or flammable precursor gases. This necessitates sophisticated safety protocols, gas handling systems, and waste abatement, adding to process complexity and cost.

Equipment and Complexity

PVD systems can often be more compact and require less physical space than their CVD counterparts. The processes can also be more easily automated for certain applications.

CVD can be a more complex process to manage due to the precise control of gas flows, temperature uniformity, and reaction chemistry required to achieve a consistent, high-quality film.

Making the Right Choice for Your Goal

Your decision should be driven by the non-negotiable requirements of your project: part geometry, substrate material, and desired coating properties.

- If your primary focus is coating complex shapes or internal surfaces: CVD is the superior choice due to its non-line-of-sight chemical reaction process.

- If your primary focus is coating heat-sensitive materials: PVD is the correct path, as it operates at significantly lower temperatures.

- If your primary focus is achieving uniform, thick coatings economically at scale: CVD often provides the best results due to its higher deposition rates.

- If your primary focus is process automation on a finished part with a simple geometry: PVD systems are often more compact, automated, and avoid high thermal loads.

Ultimately, understanding these core principles empowers you to select the deposition method that aligns perfectly with your engineering requirements.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Mechanism | Physical transfer of vaporized material | Chemical reaction of precursor gases |

| Deposition Type | Line-of-sight | Conformal (non-line-of-sight) |

| Typical Temperature | Low (<500°C) | High (often >600°C) |

| Best For | Heat-sensitive substrates, simple geometries | Complex shapes, internal surfaces, thick coatings |

| Process Analogy | Spray-painting | Baking a cake |

Still unsure which deposition method is right for your application?

KINTEK specializes in lab equipment and consumables, serving laboratory needs for thin-film deposition and material science. Our experts can help you navigate the PVD vs. CVD decision based on your specific substrate materials, part geometries, and coating requirements.

Contact us today for a personalized consultation to ensure you select the optimal process for your project's success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- What is the difference between CVD and PVD process? A Guide to Choosing the Right Coating Method

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What are the advantages of PECVD over CVD? Achieve High-Quality Thin Films at Lower Temperatures

- What are the examples of CVD method? Discover the Versatile Applications of Chemical Vapor Deposition