At its core, a benchtop muffle furnace delivers precise thermal processing capabilities in a compact, accessible form factor. The primary benefits center on providing highly uniform heat distribution, sophisticated temperature and process control, and robust safety features, all while maintaining lower relative energy consumption compared to larger industrial units.

A benchtop muffle furnace is not merely a small, high-temperature oven. It is a precision instrument designed to bring repeatable, industrial-grade thermal processing from the factory floor to the laboratory or workshop.

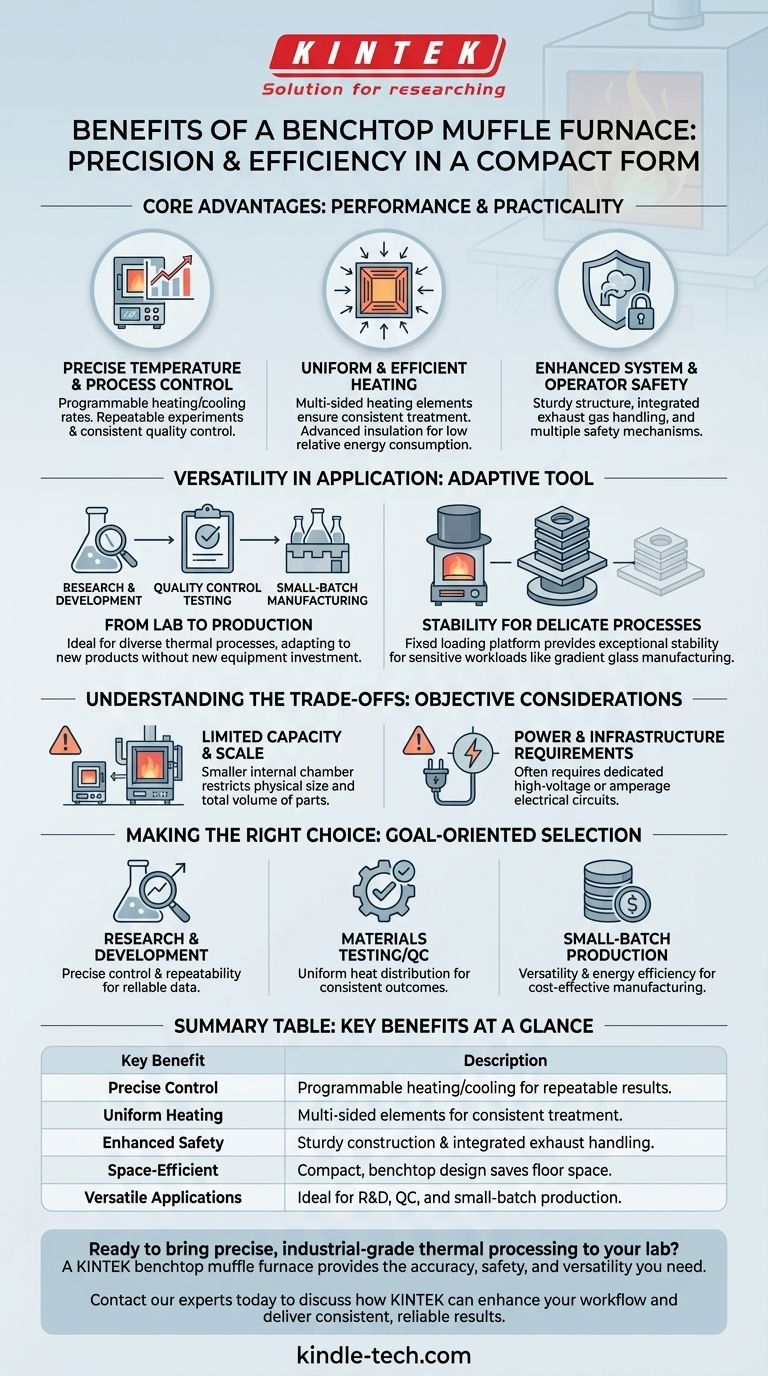

The Core Advantages of a Benchtop Design

The value of a benchtop furnace stems from its ability to combine high performance with operational practicality for smaller-scale applications.

Precise Temperature and Process Control

The defining feature of a quality muffle furnace is its ability to execute a thermal profile with high accuracy. This allows for repeatable experiments and consistent quality control in materials processing. Modern units offer programmable controls that manage not just the target temperature, but the rate of heating and cooling, as well as dwell times.

Uniform and Efficient Heating

These furnaces are engineered for uniform heat distribution, often featuring heating elements on multiple sides. This ensures that the entire workload receives the same thermal treatment, which is critical for consistent results. This design, combined with advanced insulation, leads to efficient heat protection and low relative energy consumption.

Enhanced System and Operator Safety

Designed for lab and workshop environments, these units incorporate multiple safety mechanisms. A sturdy structure provides durability, while integrated systems safely handle exhaust gases produced during processes like ashing or debinding. This built-in safety protects both the user and the integrity of the heating systems.

Versatility in Application

Beyond raw performance, the practical design of a benchtop furnace makes it a versatile tool for a wide range of tasks.

From Research to Small-Scale Production

The same furnace can be used for diverse thermal processes, from materials research and quality control testing to small-batch manufacturing of specialized components. This versatility allows an organization to adapt to new products and procedures without investing in new equipment.

Stability for Delicate Processes

Certain designs, like a top-hat furnace, feature a fixed loading platform. This provides exceptional stability for delicate workloads, such as stacked arrays of small parts or processes like gradient glass manufacturing where any shift during heating could compromise the final product.

Simplified Use and Maintenance

Benchtop units are designed to be straightforward to operate and maintain. This accessibility ensures that researchers and technicians can focus on their work rather than on managing complex industrial machinery.

Understanding the Trade-offs

While highly capable, a benchtop muffle furnace is not the solution for every thermal processing need. Objectivity requires acknowledging its limitations.

Limited Capacity and Scale

The most apparent trade-off is size. By definition, a benchtop unit has a smaller internal chamber than a floor-standing industrial furnace. This restricts the physical size and total volume of the parts that can be processed at one time.

Power and Infrastructure Requirements

While more efficient than larger models, these are still high-power devices. They often require dedicated electrical circuits with higher voltage or amperage than a standard wall outlet can provide, which can be a significant installation consideration.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your primary application.

- If your primary focus is research and development: The value lies in the precise temperature control and process repeatability, ensuring reliable experimental data.

- If your primary focus is materials testing or quality control: The key benefit is the uniform heat distribution, which guarantees consistent sample preparation and testing outcomes.

- If your primary focus is small-batch or prototype manufacturing: The furnace's versatility and energy efficiency provide a cost-effective solution for producing high-value, specialized parts.

Ultimately, choosing a benchtop muffle furnace is an investment in bringing precise, repeatable, and safe thermal processing directly to your workspace.

Summary Table:

| Key Benefit | Description |

|---|---|

| Precise Control | Programmable heating/cooling rates for repeatable results. |

| Uniform Heating | Multi-sided heating elements ensure consistent thermal treatment. |

| Enhanced Safety | Sturdy construction and integrated exhaust gas handling. |

| Space-Efficient | Compact, benchtop design saves valuable floor space. |

| Versatile Applications | Ideal for R&D, quality control, and small-batch production. |

Ready to bring precise, industrial-grade thermal processing to your lab or workshop?

A benchtop muffle furnace from KINTEK provides the accuracy, safety, and versatility you need for research, testing, and small-scale production. Our expertise in lab equipment ensures you get the right solution for your specific application.

Contact our experts today to discuss how a KINTEK benchtop furnace can enhance your workflow and deliver consistent, reliable results.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- What is the use of furnace in laboratory? Unlock Material Transformation for Your Research

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics