In modern surface engineering, the benefits of the Physical Vapor Deposition (PVD) process center on its ability to apply exceptionally hard, corrosion-resistant, and pure coatings. This advanced vacuum deposition technique enhances a component's durability and performance far beyond what traditional methods can achieve, while also offering significant environmental advantages over processes like electroplating.

The core value of PVD is not just applying a coating, but fundamentally re-engineering a component's surface at a microscopic level. It is the go-to process when performance, precision, and purity are non-negotiable requirements for the final product.

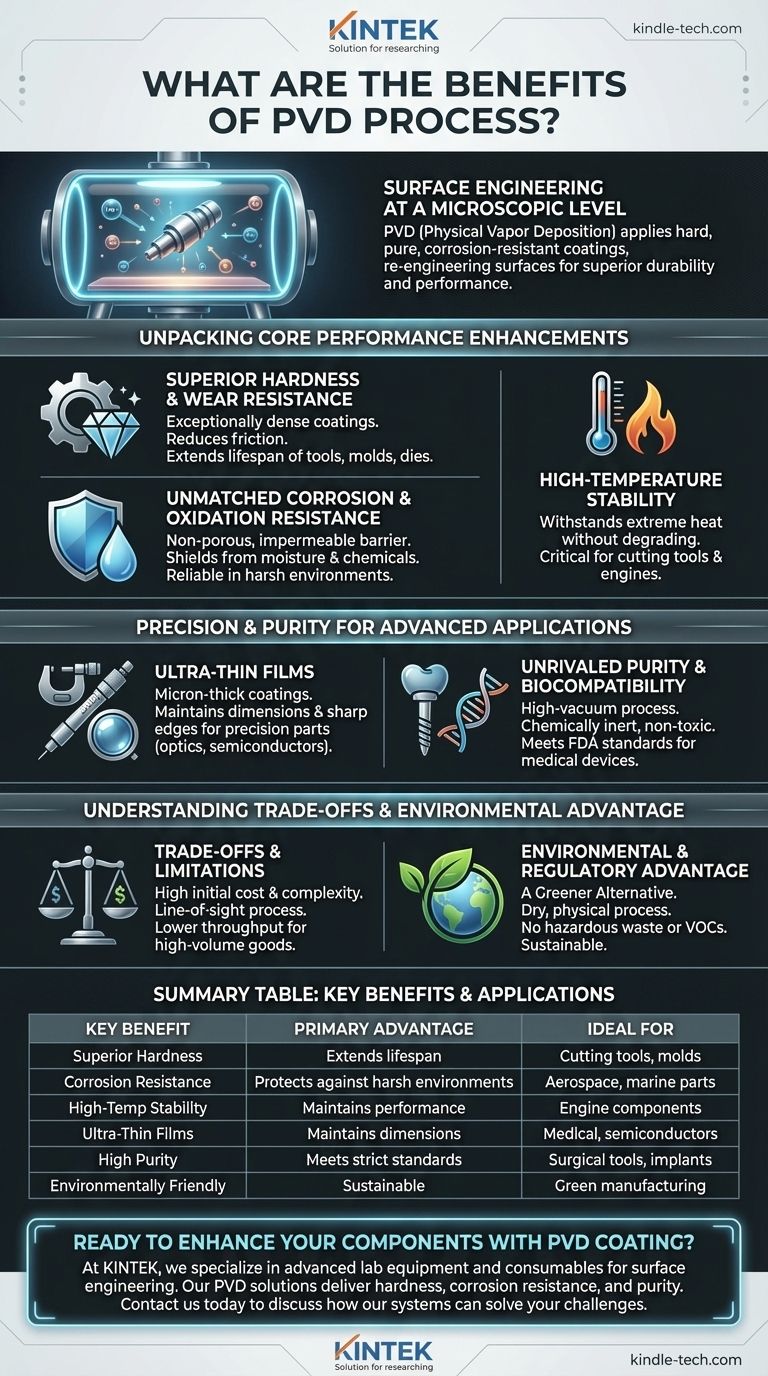

Unpacking the Core Performance Enhancements

PVD is chosen when a standard surface is not enough. The process creates a thin-film coating that is metallurgically bonded to the substrate, delivering a range of functional improvements.

Superior Hardness and Wear Resistance

PVD coatings are exceptionally hard and dense. This dramatically improves a component's resistance to abrasion, erosion, and general wear and tear.

By reducing friction between moving parts, PVD coatings can significantly extend the operational lifespan of tools, molds, dies, and other high-stress mechanical components.

Unmatched Corrosion and Oxidation Resistance

The coating layer created by PVD is non-porous and acts as an impermeable barrier. This shields the underlying material from moisture, salts, and aggressive chemicals.

This level of protection makes PVD-coated parts far more resistant to corrosion and oxidation than those treated with electroplating, allowing them to function reliably in harsh environments.

High-Temperature Stability

Many PVD coatings are designed to withstand very high temperatures without degrading, oxidizing, or losing their hardness.

This thermal stability is critical for applications like cutting tools, which generate immense heat during operation, as well as for components in aerospace and automotive engines.

Precision and Purity for Advanced Applications

Unlike bulk coating methods, PVD offers a level of control that is essential for high-technology and medical industries.

The Advantage of Ultra-Thin Films

PVD can deposit films that are just a few microns thick. This means the coating adds its protective properties without changing the part's critical dimensions, surface finish, or sharp edges.

This is vital for precision components like injection molds, optical lenses, and semiconductor devices where even minute changes in geometry would lead to failure.

Unrivaled Purity and Biocompatibility

The process takes place in a high-vacuum chamber, which prevents any contaminants from being incorporated into the coating. The result is an extremely pure, high-performance film.

Because they are chemically inert and non-toxic, many PVD coatings meet stringent regulatory standards (like those from the FDA) and are considered biocompatible, making them the standard for medical implants and surgical tools.

Understanding the Trade-offs and Limitations

While powerful, PVD is not the right solution for every application. Acknowledging its limitations is key to making an informed decision.

Initial Cost and Throughput

PVD equipment represents a significant capital investment. The process itself, which involves creating a vacuum and depositing material slowly, can have a lower throughput than bulk methods like electroplating.

This often makes it less economical for low-cost, high-volume consumer goods where ultimate performance is not the primary driver.

Process Complexity and Maintenance

Operating a PVD system requires skilled technicians and a controlled environment. The vacuum pumps, power supplies, and cooling systems all require regular maintenance to ensure consistent quality.

Line-of-Sight Deposition

PVD is a "line-of-sight" process, meaning it coats the surfaces it can "see" from the source material. Coating complex internal geometries or deeply recessed areas can be challenging and may require specialized part rotation and fixtures.

The Environmental and Regulatory Advantage

One of the most compelling reasons to adopt PVD is its minimal environmental footprint compared to legacy processes.

A Greener Alternative

Traditional coating methods like electroplating and painting involve wet chemical baths that produce hazardous sludge and volatile organic compounds (VOCs).

PVD is a dry, physical process. It produces no hazardous waste and emits no harmful chemicals, making it a clean and sustainable manufacturing choice.

Making the Right Choice for Your Goal

Selecting a coating process depends entirely on the specific goals of your project.

- If your primary focus is maximum durability and component lifespan: The superior hardness and wear resistance of PVD make it the clear choice for high-stress tools, dies, and mechanical parts.

- If your primary focus is high-purity or biocompatible applications: PVD's clean, vacuum-based process is essential for medical implants, electronics, and food-grade equipment.

- If your primary focus is high-volume, low-cost production: The investment and cycle times of PVD may make traditional methods a more economical choice, provided their performance is sufficient.

- If your primary focus is environmental compliance: PVD offers a significant advantage by eliminating the hazardous waste streams associated with older coating technologies.

Ultimately, PVD is less a simple coating and more a strategic investment in the performance, longevity, and compliance of your most critical components.

Summary Table:

| Key Benefit | Primary Advantage | Ideal For |

|---|---|---|

| Superior Hardness & Wear Resistance | Extends lifespan of high-stress components | Cutting tools, molds, dies |

| Exceptional Corrosion/Oxidation Resistance | Protects against harsh environments | Aerospace, automotive, marine parts |

| High-Temperature Stability | Maintains performance under extreme heat | Engine components, industrial tools |

| Ultra-Thin, Precision Coatings | Maintains part dimensions and sharp edges | Medical devices, semiconductors, optics |

| High Purity & Biocompatibility | Meets strict FDA/medical standards | Surgical tools, medical implants |

| Environmentally Friendly Process | No hazardous waste or chemicals | Sustainable manufacturing |

Ready to enhance your components with PVD coating?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Our PVD solutions deliver the hardness, corrosion resistance, and purity your critical components demand. Whether you're in medical device manufacturing, aerospace, or precision tooling, we provide the technology and expertise to achieve superior performance and compliance.

Contact us today to discuss how our PVD systems can solve your specific coating challenges and add value to your production process.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating