A suitable hot zone is the functional heart of any high-temperature furnace, and its design has a profound impact on operational success. Choosing the right one directly improves the quality and consistency of your production process through superior temperature uniformity, extends the furnace's service life, and significantly reduces long-term maintenance and operational costs.

The effectiveness of a furnace is not just about reaching high temperatures; it's about how efficiently and consistently it delivers that heat. A well-designed hot zone achieves this by minimizing its own energy absorption and maximizing thermal stability, directly impacting both product quality and total cost of ownership.

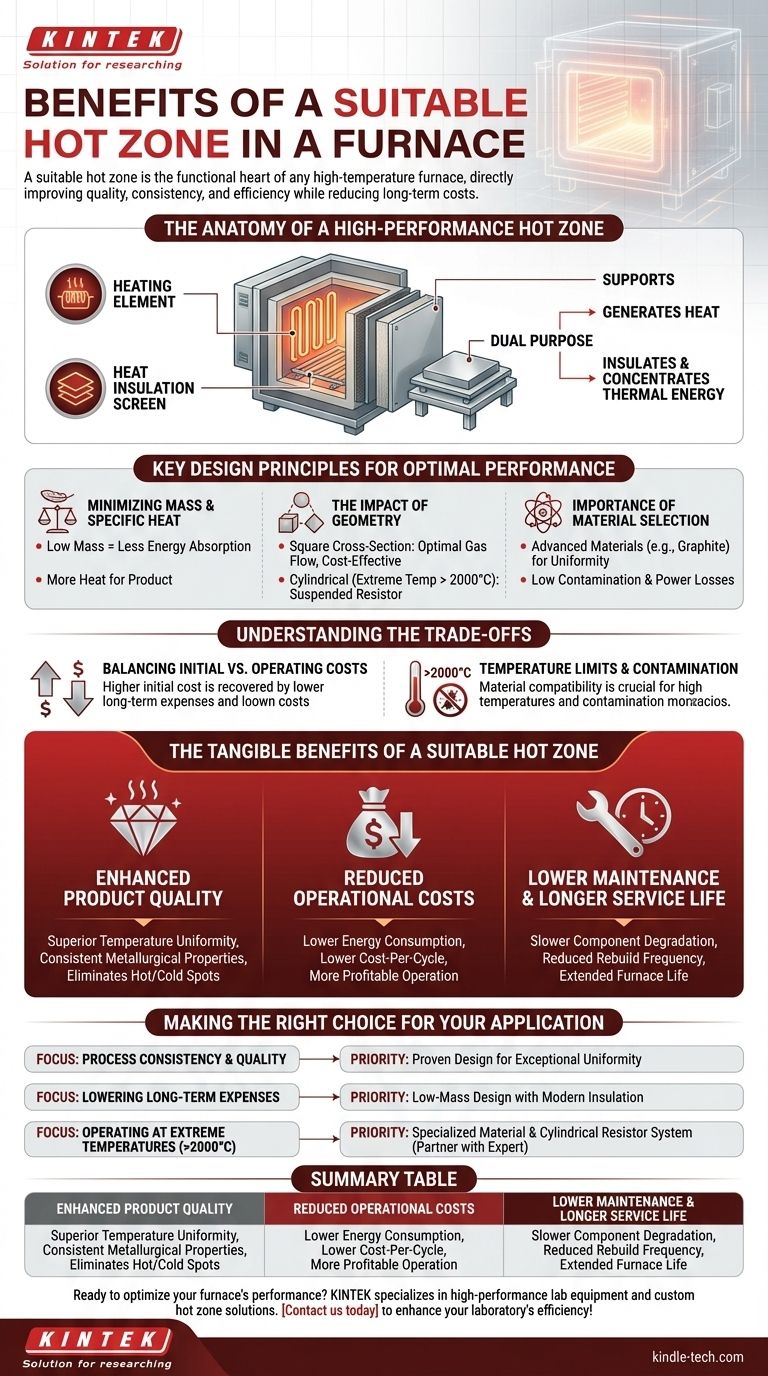

The Anatomy of a High-Performance Hot Zone

A hot zone is the core internal assembly where the heating of the workload takes place. Understanding its components and purpose is key to appreciating its importance.

Core Components

The hot zone is an engineered system primarily composed of a heating element, a heat insulation screen (or pack), and supports to hold the product being treated.

The Central Purpose: Heating and Insulating

This system has a critical dual role. Its first job is to generate heat, and its second, equally important job, is to insulate that thermal energy, concentrating it on the workload and preventing its loss to the cooler parts of the furnace.

Key Design Principles for Optimal Performance

The "suitability" of a hot zone comes down to specific design principles that govern its efficiency and effectiveness. These choices determine how well the furnace performs in a given application.

Minimizing Mass and Specific Heat

An ideal hot zone should be designed with low mass and low specific heat. This is a critical principle for energy efficiency.

Less mass means less energy is wasted heating the furnace components themselves, allowing more thermal energy to be absorbed by the actual product load.

The Impact of Geometry

The physical shape of the hot zone influences both performance and cost. A square cross-section is often preferred as it promotes optimal gas flow and is more cost-effective relative to its useful volume.

For extremely high temperatures, typically above 2000°C, options become more limited, often requiring a suspended cylindrical resistor design.

The Importance of Material Selection

Choosing the correct materials is crucial for performance. Early furnace designs were often all-metal, but modern hot zones commonly use advanced materials like graphite for insulation and components.

The right materials ensure the furnace can maintain uniform temperatures, operate with low contamination, and minimize power losses, especially at very high temperatures.

Understanding the Trade-offs

Selecting a hot zone isn't just about picking the most advanced option; it's about matching the technology to the application and budget.

Balancing Initial vs. Operating Costs

A hot zone engineered with low-mass components and superior insulation might have a higher initial purchase price.

However, this initial investment is often recovered through significantly lower long-term operating costs due to reduced energy consumption and less frequent maintenance cycles.

Temperature Limits Define Your Options

The required operating temperature is the single biggest factor dictating your design choices. As you push into higher temperature ranges, the list of viable materials and proven geometries shrinks considerably.

Contamination and Atmosphere Control

The materials used in the hot zone directly interact with the furnace atmosphere. An unsuitable material can outgas or react with the process, leading to product contamination and inconsistent results. This makes material compatibility a non-negotiable factor.

The Tangible Benefits of a Suitable Hot Zone

When these design principles are correctly applied to your specific process, the benefits are clear and measurable.

Enhanced Product Quality

The single greatest benefit is superior temperature uniformity. A well-engineered hot zone distributes heat evenly across the workload, ensuring consistent metallurgical properties and eliminating hot or cold spots that ruin products.

Reduced Operational Costs

By minimizing energy absorption and preventing heat loss, a suitable hot zone directly lowers electricity consumption. This translates to a lower cost-per-cycle and a more profitable operation.

Lower Maintenance and Longer Service Life

Using the right materials for the temperature and atmosphere means the hot zone components degrade far more slowly. This reduces the frequency of costly rebuilds and extends the overall service life of the furnace.

Making the Right Choice for Your Application

Selecting the optimal hot zone requires aligning its design with your primary operational goals.

- If your primary focus is process consistency and product quality: Prioritize a design proven to deliver exceptional temperature uniformity for your specific load and temperature range.

- If your primary focus is lowering long-term operational expenses: Focus on a low-mass design with modern insulation materials to minimize energy consumption over the life of the furnace.

- If your primary focus is operating at extreme temperatures (above 2000°C): Your choices are specialized; partner with an expert to configure the appropriate material and cylindrical resistor system for your needs.

Ultimately, selecting the right hot zone is a direct investment in the efficiency, reliability, and quality of your entire thermal processing operation.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Enhanced Product Quality | Superior temperature uniformity ensures consistent metallurgical properties. |

| Reduced Operational Costs | Lower energy consumption and cost-per-cycle. |

| Longer Service Life | Slower component degradation reduces maintenance frequency. |

Ready to optimize your furnace's performance? KINTEK specializes in high-performance lab equipment and consumables, including custom hot zone solutions tailored to your thermal processing needs. Our expertise ensures your furnace delivers consistent quality, energy efficiency, and long-term reliability. Contact us today to discuss how we can enhance your laboratory's efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi-zone Laboratory Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing