The statement that heat cannot travel in a vacuum is false. Heat travels from the Sun to the Earth through the vast vacuum of space every day. This is possible because heat transfer is not a single process but occurs through three distinct mechanisms, one of which—thermal radiation—does not require any medium to propagate.

The core confusion arises from grouping all heat transfer together. While conduction and convection require a physical medium and are stopped by a vacuum, thermal radiation travels freely through a vacuum in the form of electromagnetic waves.

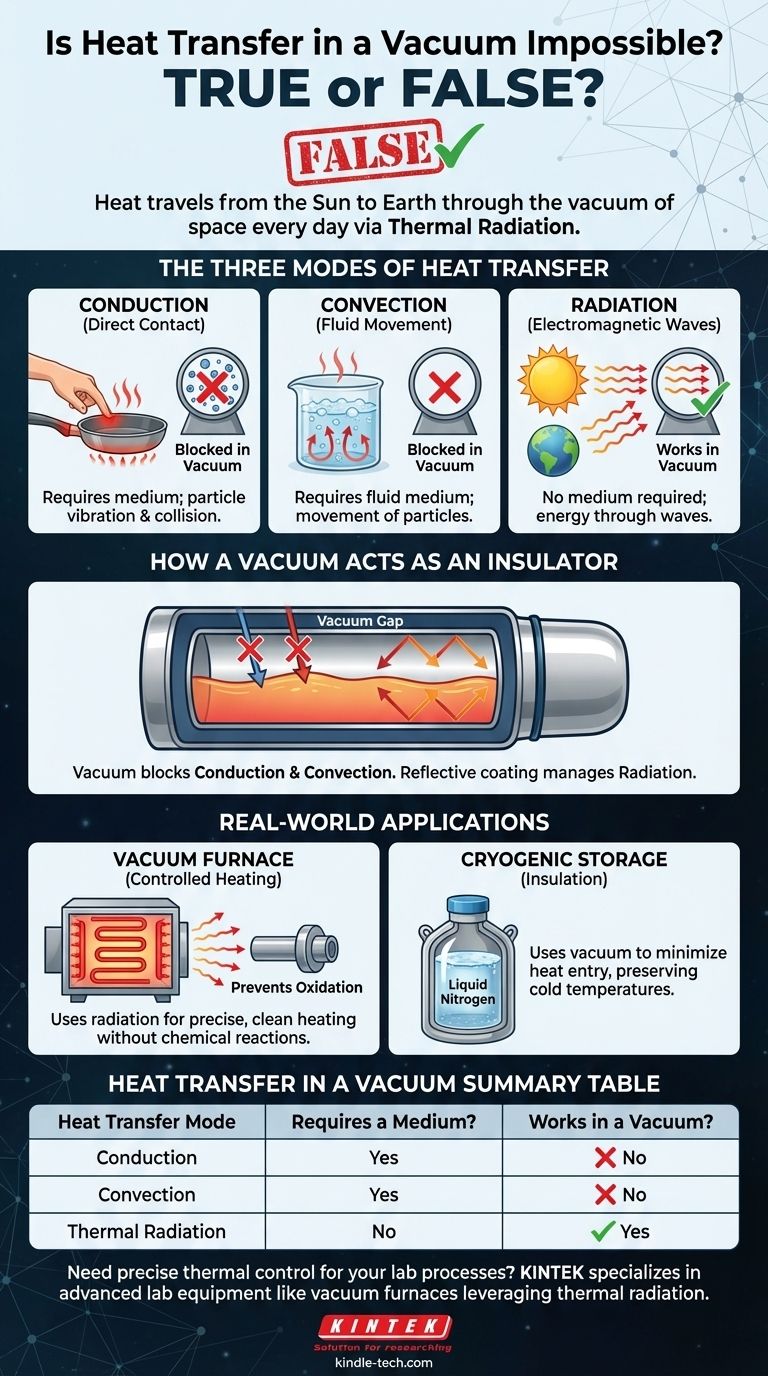

The Three Modes of Heat Transfer

To understand why heat can travel in a vacuum, you must first understand that "heat transfer" is a category, not a single event. It describes energy moving from a hotter object to a colder one through three different processes.

Conduction: Heat Through Direct Contact

Conduction is the transfer of heat through the vibration and collision of adjacent particles. Imagine holding the metal handle of a hot pan; the heat travels from the pan into your hand through conduction.

A vacuum, by definition, is a space with virtually no particles. Without particles to vibrate and collide, conduction cannot occur across a vacuum.

Convection: Heat Through Fluid Movement

Convection is the transfer of heat through the movement of fluids (liquids or gases). When you boil water, the hotter water at the bottom rises, transferring heat to the cooler water at the top. This movement is called a convection current.

Since a vacuum contains no fluid medium to move and carry energy, convection is also impossible in a vacuum.

Radiation: Heat Through Electromagnetic Waves

Thermal radiation is the transfer of heat in the form of electromagnetic waves, primarily in the infrared spectrum. Unlike conduction and convection, it does not require any medium.

Every object with a temperature above absolute zero emits thermal radiation. This is how the heat from a campfire reaches your face without the air itself having to move, and it is the exclusive method by which the sun's energy crosses space to warm the Earth.

How a Vacuum Acts as an Insulator

The common understanding of a vacuum as a great insulator (like in a thermos flask) is correct, but it's crucial to know why.

Stopping Conduction and Convection

A thermos, or vacuum flask, has an inner and outer wall separated by a vacuum. This vacuum layer is exceptionally effective at preventing heat from moving via conduction or convection between the two walls.

This is the primary reason vacuums are used for insulation. They create a barrier that physically stops the two most common forms of heat transfer we experience on Earth.

The Lingering Role of Radiation

Even in a thermos, heat can still be lost or gained through radiation across the vacuum gap. To combat this, the walls of vacuum flasks are coated with a reflective material (like silver).

This shiny surface reflects thermal radiation back towards its source, minimizing radiative heat transfer. This highlights that a vacuum only stops conduction and convection, while radiation must be managed separately.

Understanding the Trade-offs: Heat in Practice

The principles of heat transfer in a vacuum have critical real-world applications, particularly in industrial processes like metallurgy.

The Purpose of a Vacuum Furnace

In manufacturing, some metals are heat-treated in a vacuum furnace. The goal here is not to prevent heating but to create a pure, controlled environment.

By removing air, the vacuum prevents chemical reactions like oxidation (rusting) or decarburization, which would damage the metal's surface at high temperatures. The heat is intentionally applied inside the furnace, typically using heating elements that transfer energy to the metal primarily through radiation.

A Vacuum as a Tool, Not a Barrier

This shows the dual nature of a vacuum. It is used as a barrier to unwanted matter (like oxygen) while still allowing the controlled transfer of energy (heat via radiation). The process leverages the fact that radiation works perfectly well in a vacuum.

How to Apply This Knowledge

Understanding the distinction between heat transfer modes is key to solving different engineering and scientific challenges.

- If your primary focus is insulation (like in cryogenics or a thermos): Your goal is to use a vacuum to eliminate conduction and convection, then use reflective surfaces to minimize the remaining heat transfer from radiation.

- If your primary focus is material processing (like in a vacuum furnace): You are using the vacuum to create a non-reactive environment, while intentionally using thermal radiation to heat the material in a controlled way.

- If your primary focus is understanding physics (like the Earth and Sun): The key principle is that energy from a star travels across the void of space exclusively as electromagnetic radiation.

By separating the modes of transfer, you can see a vacuum not as a simple barrier to heat, but as a precise tool for controlling it.

Summary Table:

| Heat Transfer Mode | Requires a Medium? | Works in a Vacuum? |

|---|---|---|

| Conduction | Yes | No |

| Convection | Yes | No |

| Thermal Radiation | No | Yes |

Need precise thermal control for your lab processes? KINTEK specializes in advanced lab equipment like vacuum furnaces that leverage thermal radiation for pure, contamination-free heating. Whether your focus is on material processing, insulation, or research, our solutions provide the exact environment you need. Contact us today to discuss how we can support your laboratory's specific heating and thermal management challenges!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is the vacuum heat treatment cycle? Achieve Superior Material Purity and Precision

- Why is environmental control within a vacuum furnace important for diffusion bonding? Master Titanium Alloy Laminates

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality